Machining High-Quality Polycarbonate Parts

If you’re familiar with the machining process, you probably know that it is one of the most effective and efficient manufacturing processes for all industries.

And today, we’ll cover how and why polycarbonate plastic is used for machining. So, if you’re interested in machining plastic material or machining in general, you’ll find this guide very interesting.

So stay tuned and keep reading!

What is Machining Polycarbonate?

Machining is a subtractive manufacturing process that removes the material from the workpiece to create the desired shape. The process is mostly automated. However, it requires engineers and workers to make commands and to maintain the process smoothly.

But mostly, machining polycarbonate is a computer-operated manufacturing process that is run by extensive tools in dedicated facilities.

Why is machining polycarbonate so popular?

As everyone knows that polycarbonate sheet offers excellent processability.

Machining polycarbonate is considered one of the best ways to get a plastic part in most industries, which is for a good number of reasons. But a suitable machining solution will allow you to have the desired parts precisely like your design.

In a cost-efficient and effective way, machining can produce the replica of any critical design in a large number quickly, which makes it a favorite among both buyers and manufacturers.

Plexiglass sheet also offers good processability, but it is the different way between machining acrylic and polycarbonate. For example, you can cold-bend a polycarbonate sheet, but you have to heat-bend an acrylic sheet. This article is to teach you how to bend acrylic sheets.

Can you machine plastic?

The answer is YES and NO. Plastic can be machined, but you have to ask which one? Because stronger plastics can be machined quickly and successfully while soft plastics are not suitable for machining.

Initially, only metal elements were considered to be machined. Because of the increased demand for complicated plastic designs and the plastic industry’s improvement, plastic has also become a good component of this process.

Today almost 82% of the plastic parts are the result of machined plastic. As it offers excellent tolerance and surface finishing, the demand for plastic machining is increasing day by day.

Machining Polycarbonate

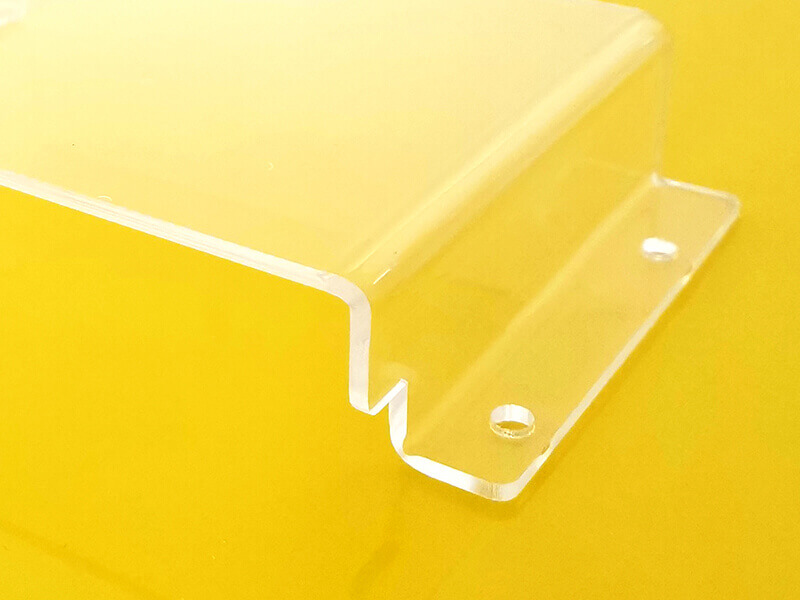

As I have said earlier, only the most substantial grades of plastic materials can be machined. And you probably know how strong and rigid polycarbonate is.

So, machining polycarbonate is very easy and provides an excellent result. Or in other words, we can say that the machinability of the polycarbonate plastic is perfect.

Polycarbonate offers great tolerance and excellent surface finishing, making it more eligible for critical industries like aerospace or marine.

Why use polycarbonate machining?

Machining is great for critical and complex designs. It allows you to replicate a very complex design accurately in less time and at a low cast.

When we talk about the elements for this process, metal comes first in our minds. But because of the advancement of technologies and the exceptionally well performance of polycarbonate plastic, it has become a great option for this.

Today, machined polycarbonate parts and products are everywhere. From the marine industry to the aerospace industry, polycarbonate machined parts are performing well in all sectors.

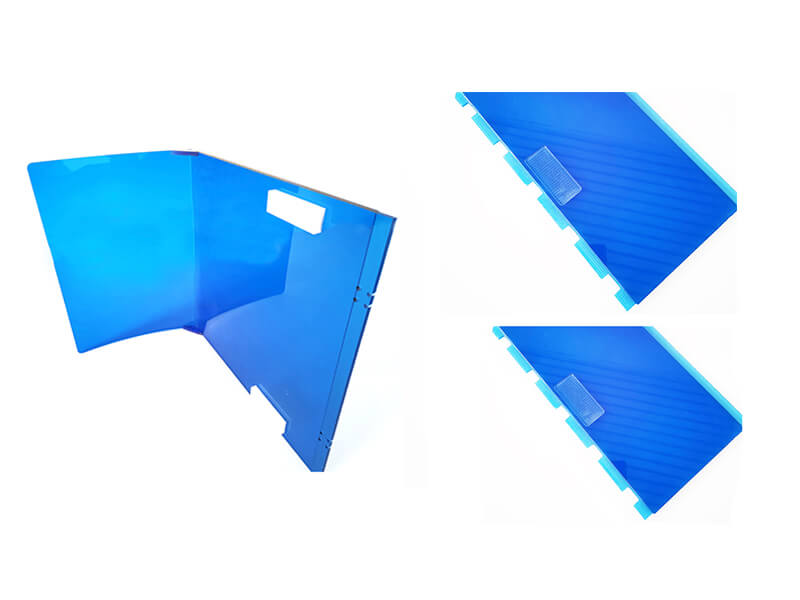

Custom Polycarbonate Parts

Polycarbonate is widely used for greenhouses, roofing, doors and other applications. But because of the extreme strength and rigidity it offers, it is now used in various other industries.

Like automotive, medical and aerospace use custom polycarbonate parts regularly. Wherever possible, buyers try to replace the metal parts with plastic.

The reason is quite simple, aluminum or other metal is significantly heavier than plastic. And for the automotive or aerospace industry, weight is a significant factor to consider.

So, the demand for custom PC parts arose. There are many custom machined polycarbonate parts that are being manufactured for medical, aerospace, automotive, and various other industries.

The parts are very lightweight with high precision and better build quality. These qualities make it a great alternative for metal parts.

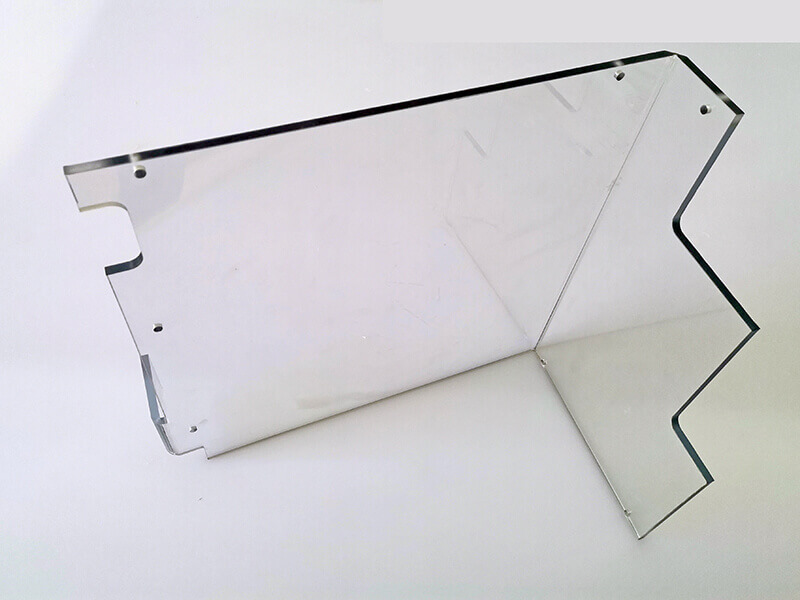

How to Machine Polycarbonate?

Machining plastic is not very different from machining metals like aluminum. However, the process becomes a lot easier and more efficient with plastic. As it is easier to cut compared to metal, manufacturers need less strength in their cutting tools.

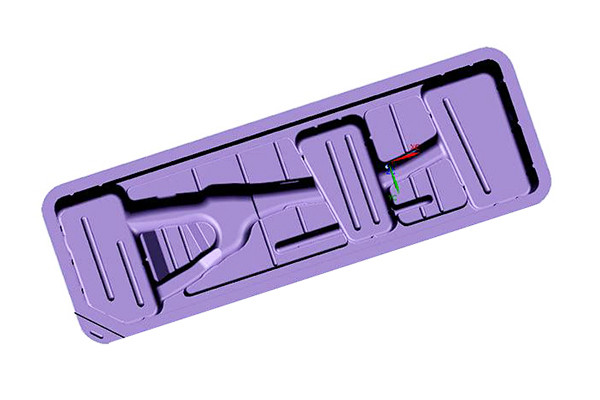

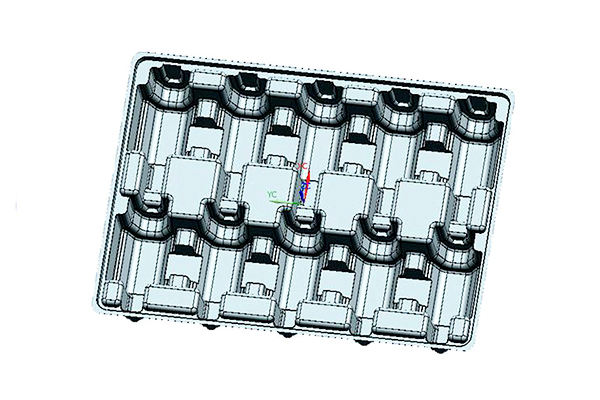

The process begins with a design. Buyers usually have a design of their desired product. We, manufacturers, make a CAD/CAM 3D model on it in the computer-based on that design.

As you know, the process is highly dependent on computers and automated cutting tools. We need to give the exact command to make this work.

After the design is done, we give instructions to the computers which control the cutting tool. The tool then removes unwanted elements from the polycarbonate workpiece and based on the design, creates the final parts. UVPLASTIC is a leading manufacturer of polycarbonate sheets in China, meantime, the subsidiary-UVACRYLIC is a ONE-STOP supplier of plexiglass. They provide an integrated machining solution.

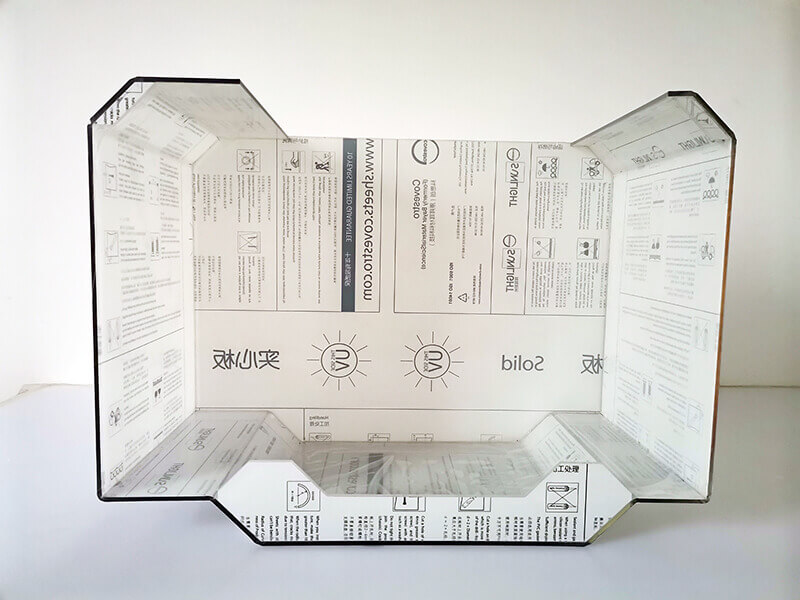

Can UVPLASTIC Help You with Polycarbonate Machining?

UVPLASTIC is one of the leading and most reputable plastic manufacturing companies in China. With over 16 years of experience, we have been serving both local and global suppliers with quality plastic parts and materials.

If you need custom or premade machined polycarbonate parts, you’re in the right place! UV Plastic offers the highest quality and precise CNC machined polycarbonate parts that will satisfy all your requirements.

Not only that, we offer extensive support from the beginning stage of your project to make it successful. Starting from your design to choosing the suitable material, you’ll find UV Plastic by your side all the time.

Our state-of-the-art machining tools and dedicated facility with highly experienced engineers will ensure you get the best output from us.

Final Thoughts

Machining is an excellent method of manufacturing. And it makes the application of plastic even more useful and suitable for critical parts.

If you require exact parts with great strength and lighter weight, polycarbonate machining is the right option for you.

If you need any help or information on this, feel free to reach out to us and we will be happy to assist you on your next project.