Application of Anti-Static/ESD Polycarbonate Sheet

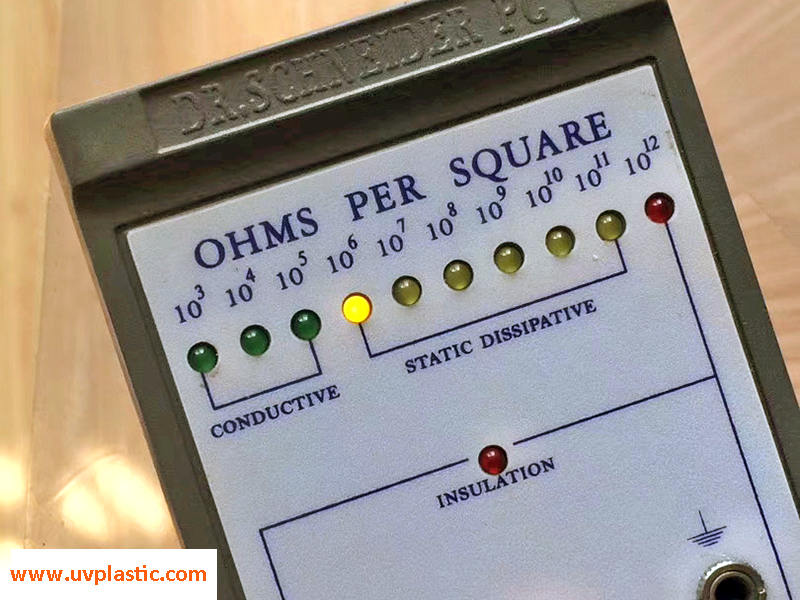

Anti-static polycarbonate is a metal and plastic-coated polycarbonate layer that prevents static electricity from developing on the plastic sheets. We also know it as electrostatic dissipative (ESD) polycarbonate. ESD is effective at preventing and controlling the generation of static electricity on the polycarbonate sheet’s surface.

Anti Static polycarbonate sheeting is extremely strong and resistant to abrasions and chemicals. You can cut it into a variety of shapes and sizes according to specific industrial requirements. Weather, humidity, and fog do not affect the anti-static polycarbonate sheet. In the meantime, some of its excellent features are lightweight, chemical resistant, flame retardant, and enhanced hardness.

Since it is resistant to turbocharging throughout all situations, manufacturers worldwide are using these anti-static polycarbonate sheets regularly.

Application of Anti-Static Polycarbonate Sheet

Anti-static polycarbonate sheets are famous for their excellent features. When properly grounded, an anti-static polycarbonate sheet resists static electricity and cannot produce an electrostatic charge. It can protect against electrostatic damage and quality defects. This anti-static plastic sheet is ideal for production and assembly environments that are electrostatically sensitive.

Here are the main applications of anti-static polycarbonate sheets that manufacturing companies use widely.

Electrical and Electronics Industry

ESD polycarbonate plastic is an excellent option for manufacturing applications where ESD could cause rejects or latent damage to sensitive electronic devices. In the semiconductor, electrical, and micro-manufacturing industries, it is perfect for use.

We are all probably aware that electrostatic discharge can damage electrical components and equipment. And, as these pieces of equipment get smaller and smaller, their vulnerability to static damage grows. Several changes have been made in the electrical and electronics industry to reduce losses caused by electrostatic discharge.

Anti-static sheets in operating rooms, for example, can help avoid static discharges, which can cause machine overload or even explosion. It also provides workers with a safe working environment. It often transports electronic equipment that is susceptible to static discharge in antistatic bags.

Apart from antistatic properties, antistatic polycarbonate sheets are popular for their chemical, wear, and scratch resistance.

Oil and Gas Industry

The oil and gas industry uses anti-static polycarbonate sheets in areas where there are many flammable liquids. Electrostatic charges can build up in such compounds, causing them to burst. Especially for the pipelines and hoses which transport oil and gases from one location to another.

Manufacturers use antistatic coatings on pipelines and hoses to prevent fires and explosions caused by static sparks. This reduces the risk of electrostatic discharge.

Manufacturers use filters in refining plants to clean oil until it is transferred. Dust and other particles, which are often attracted by static buildup, can clog these filters.

In this situation, antistatic coatings help avoid static buildup, which can lead to dust accumulation. It’s essential to keep in mind that dust can clog the filter and cause harm.

Friction is also a medium for static buildup, which is pretty common in the oil and gas industry. Anti Static polycarbonate sheets on fuel tanks are often used to prevent this. These coatings pull static electricity away from gasoline tanks.

Steel Industry

Anti-static polycarbonate sheets have become more common among manufacturers in this industry. Because they help them meet their steel equipment delivery requirements to other suppliers and end-users.

Manufacturers use it to help deaden tone, provide wear and abrasion resistance, nonstick release, and partial scratch protection in products and finishes.

Aerospace Industry

The aviation industry is popular for carrying heavy loads and a high volume of traffic. If it permits the static discharge to build upon aviation surfaces, substantial risks and damages can occur.

As a result, the anti statistical formulation is used to avoid static accumulation on floors and equipment surfaces in this situation. This protects aviation personnel and any facilities that could be damaged as a result of the incident.

Anti Static polycarbonate sheet is ideal for preventing static accumulation on equipment surfaces and floors in the aviation industry. Moreover, static wicks are installed in airplanes to help avoid the static buildup that could cause lighting to form. Anti-static polycarbonate sheets are also used on aircraft transparencies and other body materials.

Textile

The anti-static polycarbonate sheet is used in the textile industry to prevent electrostatic damage. It also extends the life of textile components by increasing wear resistance and lowering friction while improving nonstick efficiency. Moreover, it helps to reduce worker safety risks caused by static buildup on surfaces.

It is applied in many areas, including machine rolls, dryer casings, and fabrics. Besides, you will find anti-static sheets on surgical clothing, machinery, and floors to help minimize dust attraction.

Food Processing Industry

Anti-static polycarbonate sheets are usually used to improve the efficiency of food processing equipment, specifically on dishwashing machines, bakeware, cookware, flooring, and other food-processing machinery.

We all know that the food and beverage industries require high hygiene standards. An anti-static polycarbonate sheet does not attract contaminants. That’s why it is perfect for food processing without affecting the quality of the end product.

Automotive Industry

In the automotive industry, anti-static coatings are used to minimize friction, enhance corrosion resistance, and extend automotive components’ lives.

Body shafts, metal parts, bearings, and handguns are often covered with an ESD coating. It’s often used on surfaces in automobiles that are vulnerable to static buildup.

Home Applications

Nowadays, antistatic coatings are seen on floors at home to help avoid electrostatic discharge. Because it can destroy machinery, cause fires, and even shock residents. Specifically, on the kitchen cookware and cutlery, anti-static polycarbonate sheets make them non-stick, wear-resistant, and simple to clean.

Conclusion

Anti-static Polycarbonate Sheet is easier to fold, slice, thermoform, print, or drill depending on the particular design specifications. Moreover, it helps to remove charges and dust from the soil. That’s why it is prominent in multiple industrial areas like doors, windows, covers, and guards for electronic equipment, assembly machines, instruments, conveyor line covers, transparent room partitions, process equipment, and automation equipment.