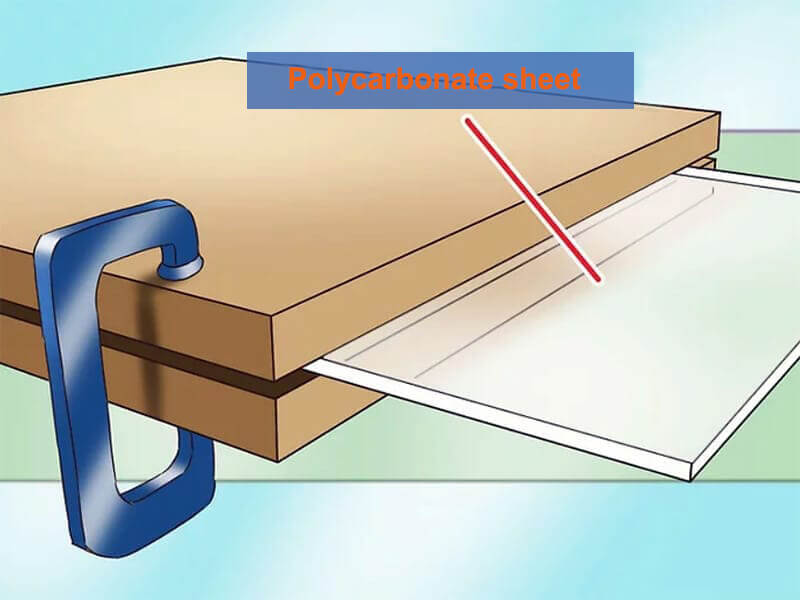

Bending Polycarbonate

Related Machining Process

Bending polycarbonate is a popular process for machining custom polycarbonate parts when you use it for windscreens, Protective covers of machines, or gauges. But do you know how to bend polycarbonate? And how to choose a supplier for your bending polycarbonate parts? Today, we will discuss it.

What is polycarbonate?

Polycarbonate is a tough, transparent engineering plastic. It offers outstanding strength, stiffness, and impact resistance. It can be manufactured into flat sheets, rods, tubes, and complicated shapes by injection molding. It also offers good weather resistance when used outside. Otherwise, the natural color is transparent and can be manufactured to be colored. Polycarbonate sheets can be solid and hollow types, the standard widths are 1220mm and 2100, Max. width is 2700mm. Length can be customized because it is extruded. Here are some polycarbonate sheets on the market:

| Polycarbonate type | Description | Thickness range | Width |

|---|---|---|---|

| Solid polycarbonate sheet | A flat polycarbonate sheet, transparent or colored. | From 1mm to 40mm | 1220mm, 2100mm, 2700mm |

| Multi-wall polycarbonate sheet | It is a hollow sheet, transparent or colored, twin wall, honeycomb wall. | From 4mm to 40mm | 1220mm, 2100mm |

| Corrugated Polycarbonate | Normally used for a roofing sheet | From 0.8mm to 2mm | From 600mm to 1200mm |

| Polycarbonate film | Used for a sign, eyeglass, printing parts | From 0.125mm to 0.8mm | 1220mm |

| Polycarbonate rod | For more information, please send an e-mail to [email protected] | ||

| Polycarbonate tube | For more information, please send an e-mail to [email protected] |

Bending polycarbonate methods

There are many methods to bend polycarbonate sheets according to shape, size, thickness, quantity, and the tools that you have. Let’s discuss them one by one:

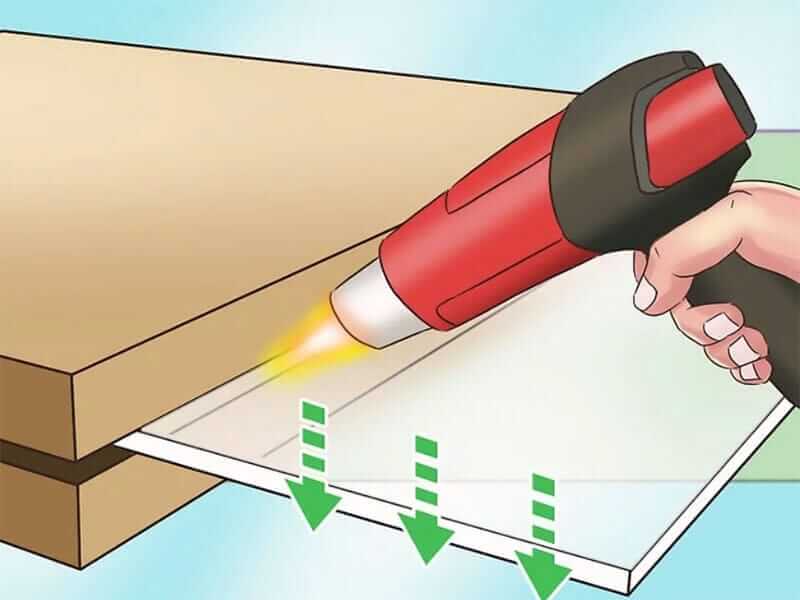

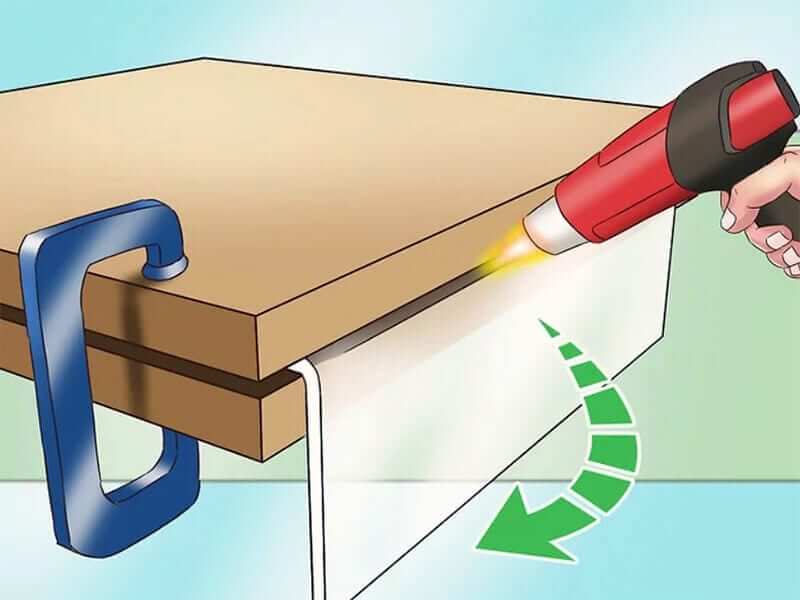

Bending Polycarbonate by heat gun

It is a manual process to bend polycarbonate, therefore, the operator needs to be patient enough, or the small bubbles will appear in the heating area. The operator just heats polycarbonate sheets back and forth to the soft temperature from 260 to 320 Fahrenheit degrees (130 or 160 centigrade degrees). If you can’t test the temperature, you can try to bend it when heating.

| Bending Method | Advantage | Disadvantaged |

|---|---|---|

| By heat gun | 1. Very easy to work; 2. Cheap tool; 3. Good for small parts; 4. Easy to bend 90 degrees; | 1. Low accuracy; 2. Low efficiency; 3. Maybe small bubbles appear; 4. Not suitable for big parts; 5. Maybe a wooden mold is needed; |

Tips for bending polycarbonate by heat gun

Bending Polycarbonate by hot wire angle bender

Hotwire angle bender is a popular tool to bend polycarbonate to some angles at the factory and small workshop. The metal wire will be heated by using electricity. Here are some tips when bending polycarbonate by hot wire bender:

| Bending Method | Advantage | Disadvantaged |

|---|---|---|

| By hot wire angle bender | 1. Efficiency; 2. Excellent accuracy with mold; 3. Can bend polycarbonate with a large range of thickness; 4. Without small bubbles; 5. Friendly with small quantities and big quantities; | 1. Not an automatic tool; 2. Need electricity; |

Curving Polycarbonate roofing sheet

Polycarbonate sheets can be curved to an arch when used as roofing sheets without heating according to the minimum radius.

Minimum curving radius = thickness multiply by 150

Such as, if you curve 5mm polycarbonate,the minimum radius is 750mm

Tips for installing polycarbonate roofing sheet

| Thickness of Polycarbonate | Minimum Bending Radius |

|---|---|

| 2 mm | 300 mm |

| 3 mm | 450 mm |

| 4 mm | 600 mm |

| 5 mm | 750 mm |

| 6 mm | 900 mm |

Cold Bend Polycarbonate by press brake

Polycarbonate is a group of thermoplastics and practically unbreakable and can be bent cold in various thicknesses. Press brake can bend polycarbonate sheet with varies thickness from 1.5mm to 6mm.

| Bending Method | Advantage | Disadvantaged |

|---|---|---|

| By press brake | 1. High efficiency; 2. Low cost; 3. Without small bubbles; 4. Friendly with small quantities and big quantities; 5. Angle tolerance is ±5 degrees; 6. Size tolerance is ±0.5 mm; | 1. The press brake is expensive; 2. Need experience in bending polycarbonate; |

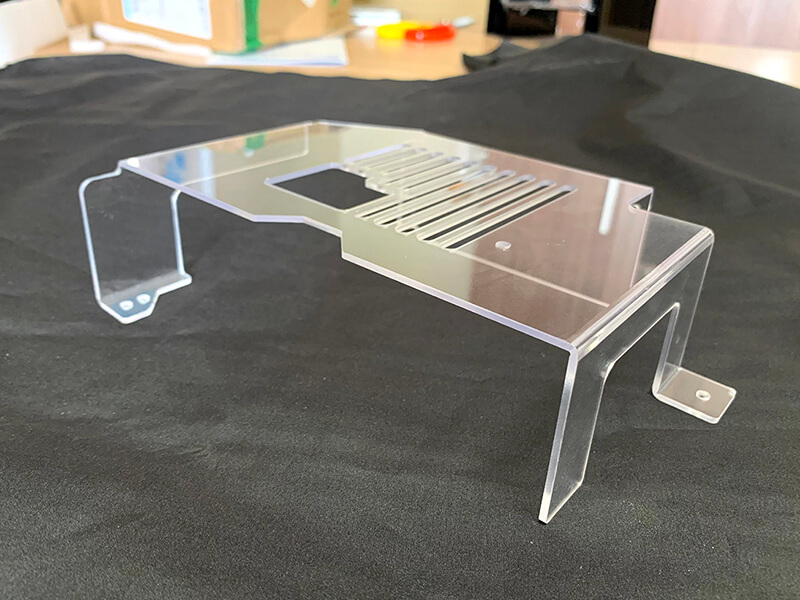

Bending polycarbonate by Thermoforming

When you need to bend polycarbonate in a high-quality and intricate shape, thermoforming polycarbonate will be a good choice. The normal methods are vacuum forming, pressure forming, and injection forming.

| Bending Method | Advantage | Disadvantaged |

|---|---|---|

| By thermoforming polycarbonate | 1. High efficiency; 2. Excellent surface; 3. Friendly with intricate shape; 4. Best method for windshield; | 1. The mold is expensive; 2. Not good for small quantities; |

Frequently Asked Questions about Bending Polycarbonate

Can you bend polycarbonate?

Yes, you can bend it according to the minimum curving radius.

Can polycarbonate be bent with heat?

Yes, the suitable bending temperature is from 260 to 320 Fahrenheit degrees (130 or 160 centigrade degrees).

How do you bend polycarbonate by hand at home?

You can use a heat gun to bend thicker polycarbonate sheets and use a manual brake to bend a thin polycarbonate sheet.

Can you fold polycarbonate?

Yes, you can fold polycarbonate sheets with less than 3mm thickness.

At what temperature does polycarbonate soften?

The soften polycarbonate temperature is from 260 to 320 Fahrenheit degrees (130 or 160 centigrade degrees).

Can you bend twin wall polycarbonate?

Yes, twin wall polycarbonate can be cold cold-curved, the minimum curving radius is 175 times more than the thickness.

How long will polycarbonate last?

It is about 10 years or 15 years.

Conclusion

Bending polycarbonate is one of most popular the machining methods. If you are looking for a supplier of bending polycarbonate, UVPLASTIC will be a trustworthy one. Send mail to [email protected], you will know more information.

UVPLASTIC is one of the leading manufacturers of polycarbonate in China, meantime, we provide machining services. Today, we are providing machining services to more than 2000 clients from more than 40 countries.