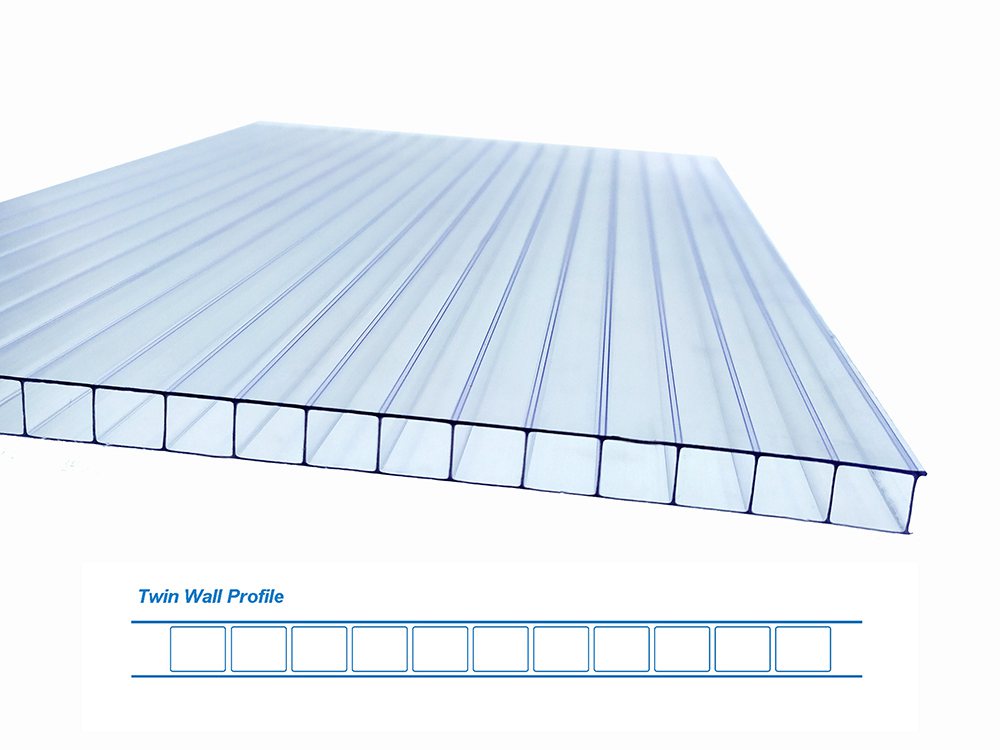

Twin-Wall Polycarbonate Sheet

Product Description

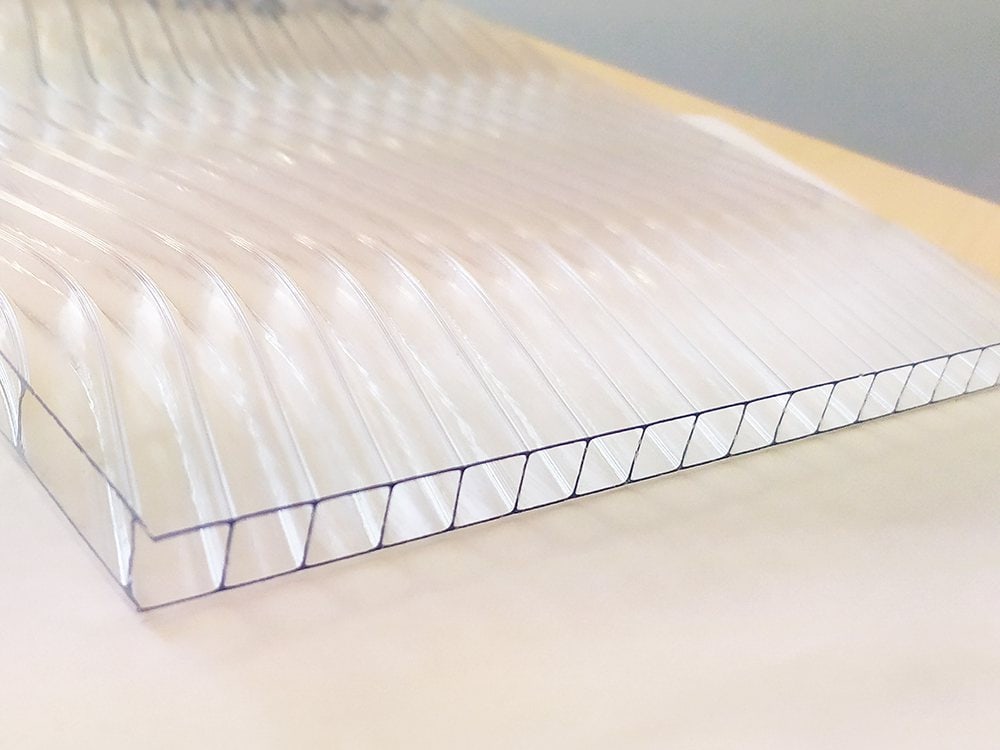

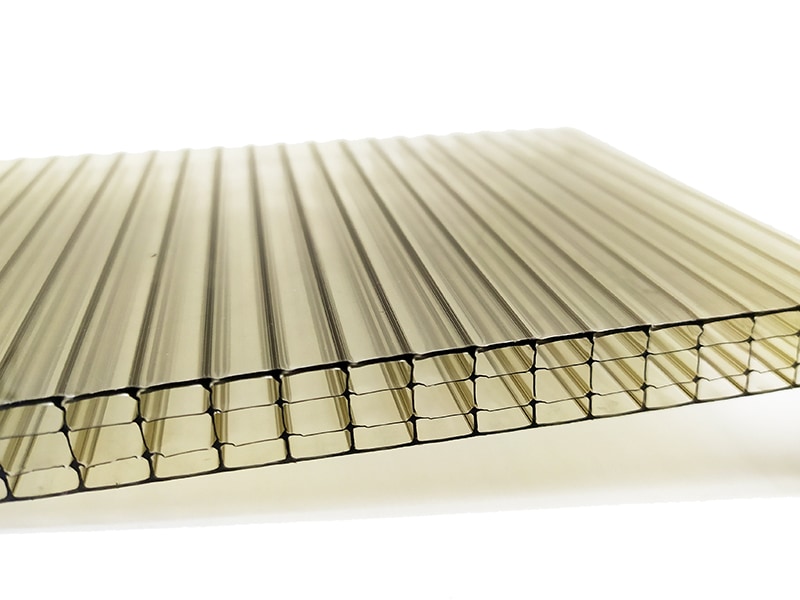

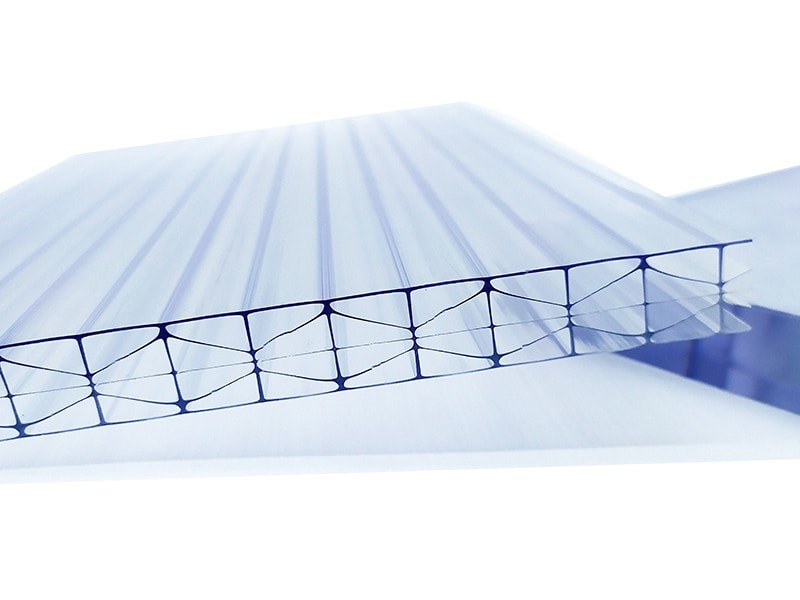

Twin-Wall Polycarbonate Sheet offers a rectangular insulation space inside to reduce thermal energy transfer. Meantime, it creates a stronger, lighter weight and more impact resistance structure. Some people call it a “double-wall polycarbonate sheet”.

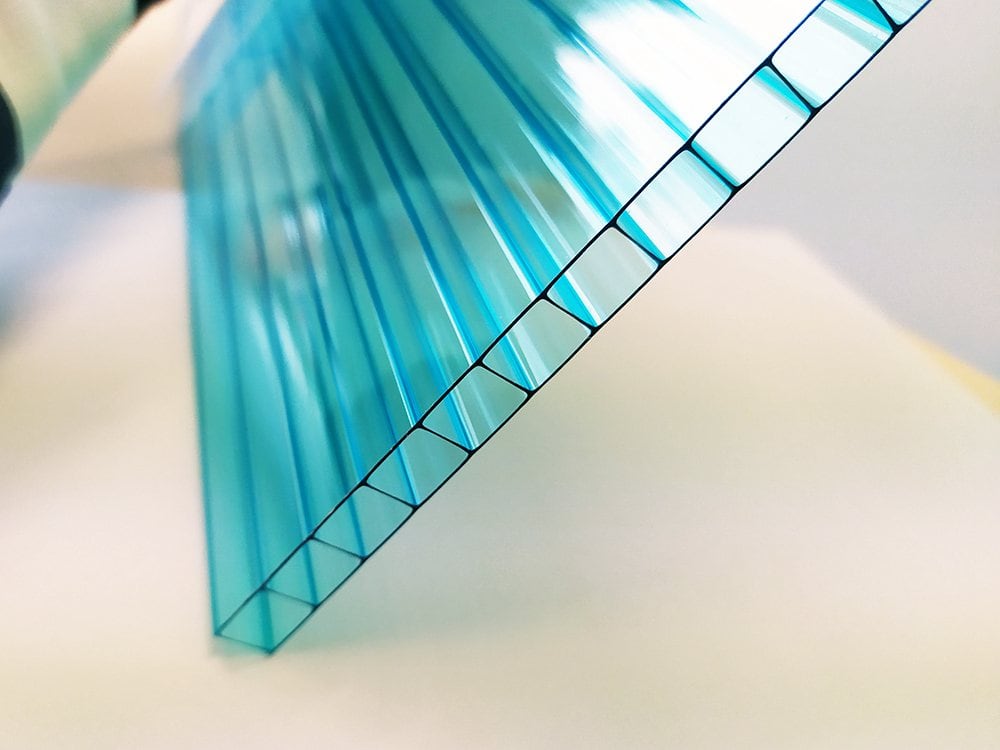

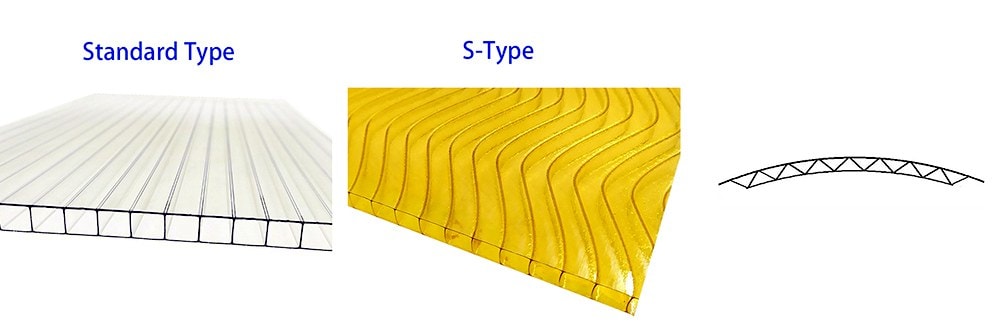

UVPLASTIC offers standard and S-Line twin wall polycarbonate sheet, the thickness ranges from 4mm to 12mm. Clear and tinted colors are available.

With the co-extruded UV protective layer, twin wall polycarbonate sheet can be used exterior, it offers great weatherability even under intensive ultraviolet rays, the lifespan is more than 10 years or 15 years.

Twin wall polycarbonate sheets are used widely for the commercial greenhouse, mini-greenhouse, sunroom, garden Restaurant, etc.

Product Specification

| Model | Thickness | U-Value (W/m²·°K) | Light Transmission, clear, % | Width 700 (mm) | Width 1050 (mm) | Width 2100 (mm) |

|---|---|---|---|---|---|---|

| UVMPC-TW(S)-4 | 4 mm | 3.96 | 82% | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-6 | 6 mm | 3.56 | 80% | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-8 | 8 mm | 3.26 | 79% | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-10 | 10 mm | 3.02 | 78% | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-12 | 12 mm | 2.78 | 76% | ✔ | ✔ | ✔ |

- Other Typical Dimensions are available, such as 4×8 ft, 2x3m;

- Max. Length is 12m;

- Custom width is available;

- Polycarbonate fabrication services are available;

- It is free to cut polycarbonate to size according to clients’ requirement;

| Model | Description |

|---|---|

| UVMPC-TW-U1 | Standard type Twin wall polycarbonate sheet with co-extruded UV protective on one side |

| UVMPC-TWS-U1 | S-line twin wall polycarbonate sheet with co-extrude UV protective on one side |

| UVMPC-TW-U1A | Standard type twin wall polycarbonate sheet with co-extrude UV protective on one side and anti fog coating on inside for greenhouse |

| UVMPC-TWS-U1A | S-line twin wall polycarbonate sheet with co-extrude UV protective on one side and anti fog coating on inside for greenhouse |

| UVMPC-TW-U2 | Standard type twin wall polycarbonate sheet with co-extrude UV protective on two side |

| UVMPC-TWS-U2 | S-line twin wall polycarbonate sheet with co-extrude UV protective on two side |

Physical Properties

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Light transmittance | D-1003 | % | >76 |

| Heat deflection temperature (HDT) | D-648 | °C | 140 |

| Service Temperature – Short term | °C | -50 to +120 | |

| Service Temperature – Long term | °C | -40 to +100 | |

| Impact falling dart | ISO 6603/1 | J | 40-400 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Practical thermal expansion/contraction | mm/m | 3 |

Default third-party testing organization is SGS

Color Description

| Model | Clear | Bronze | White opal | Green | Blue | Custom Color |

|---|---|---|---|---|---|---|

| UVMPC-TW(S)-4 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-6 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC(S)-TW-8 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-10 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-TW(S)-12 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |