Best Polycarbonate Roofing Panels You Could Find

Leading Manufacturer of Polycarbonate Roofing System in China

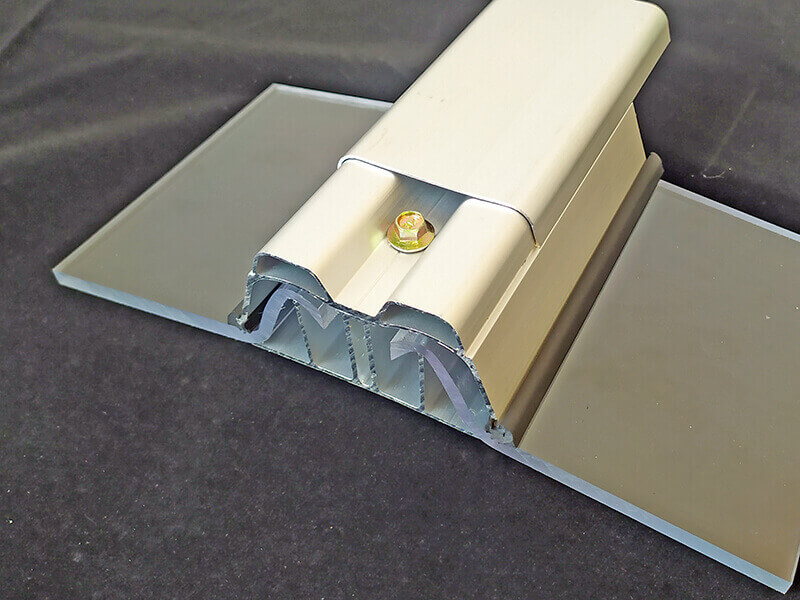

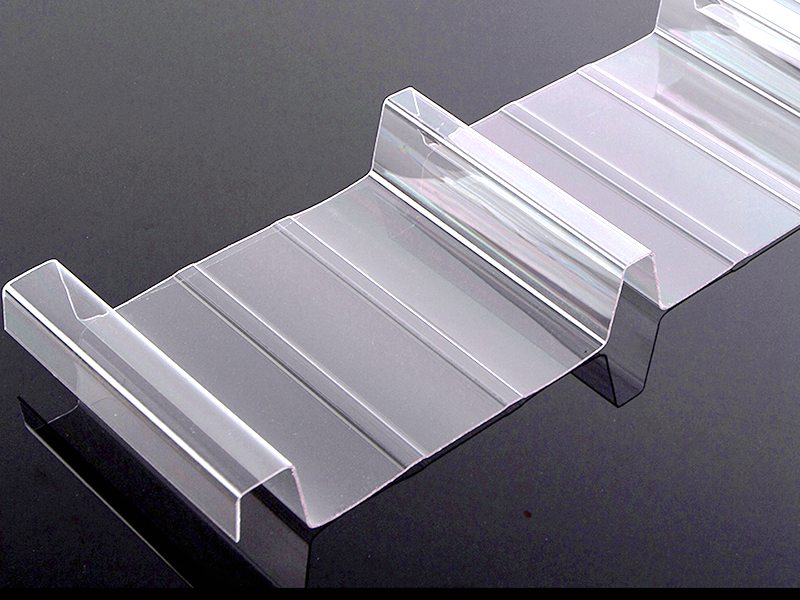

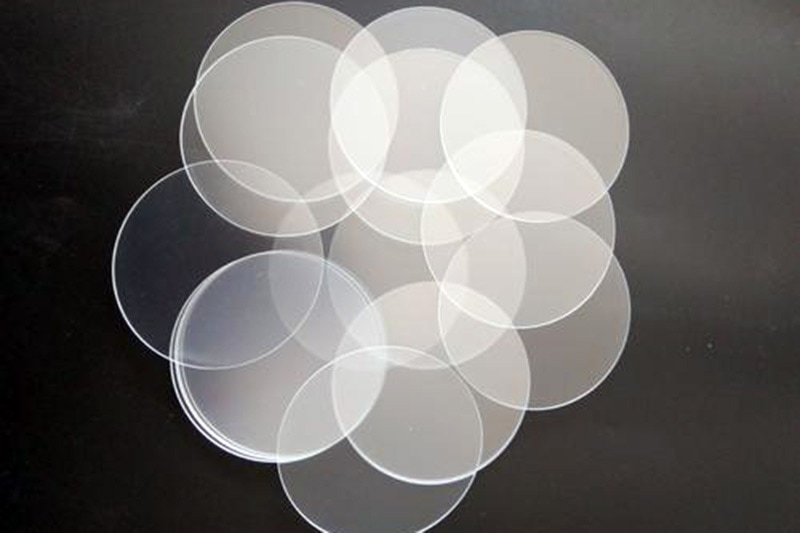

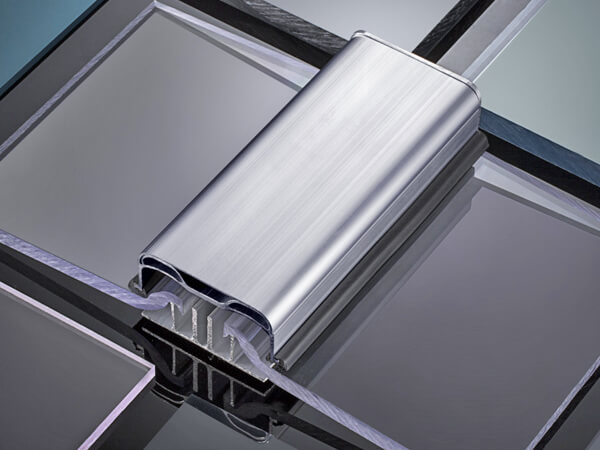

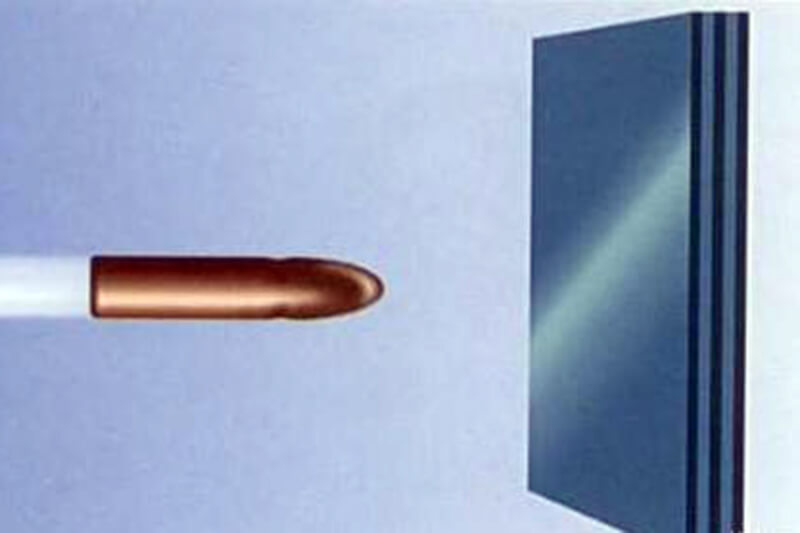

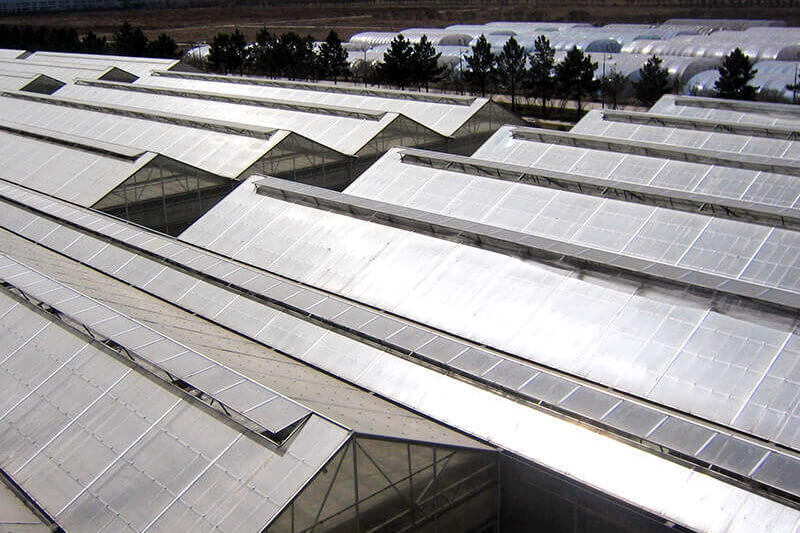

Polycarbonate Roofing Panel is one of the integrated roofing systems with “lock catch structure”, which is safe, durability, excellent impact resistance, and easy to install, it is also called “polycarbonate roofing sheets”, which is the best roofing solution for a commercial building, industrial building, stadium, airport, railway station, skylight, greenhouse, walkway, carport, etc.

UVRPC is the family code of UVPLASTIC™ Polycarbonate Roofing Panels, which offers standard widths and flexible length options. Meantime, UVRPC Polycarbonate Roofing Panels have different thicknesses and structures according to different loads, you can find detailed information from the following Products Specification.

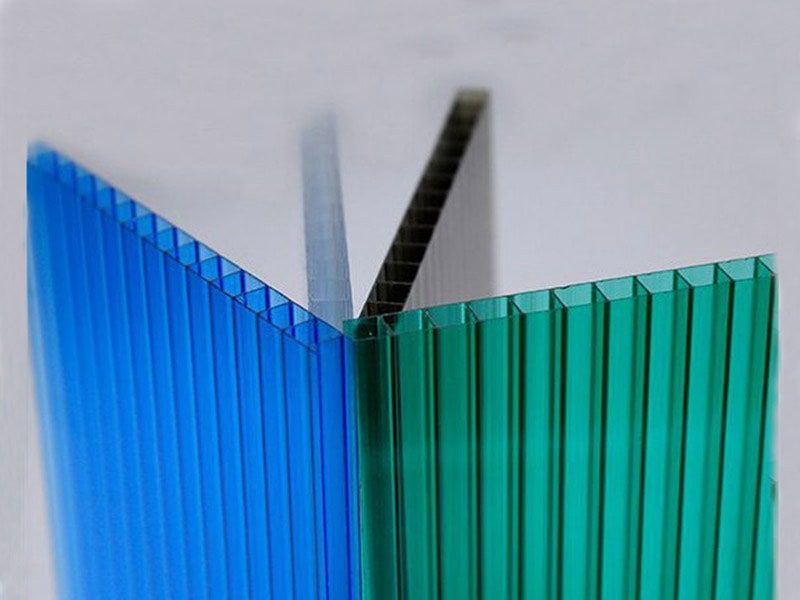

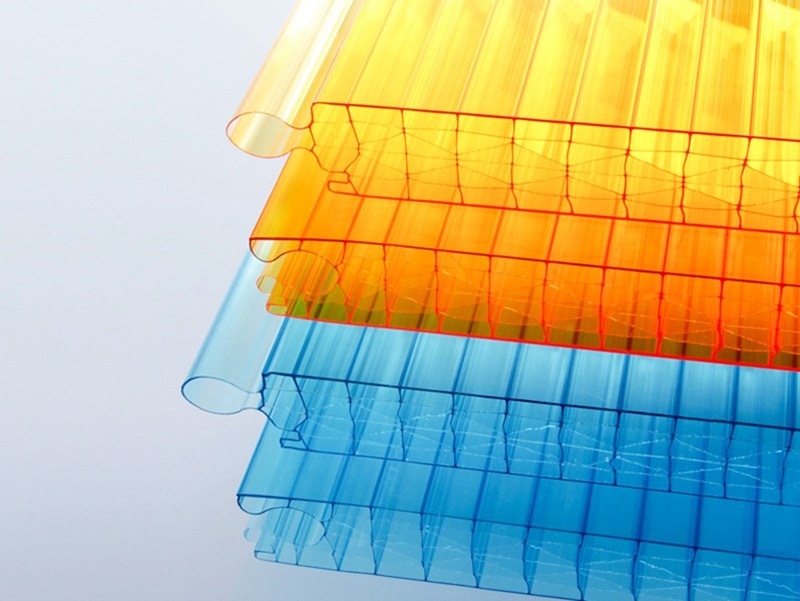

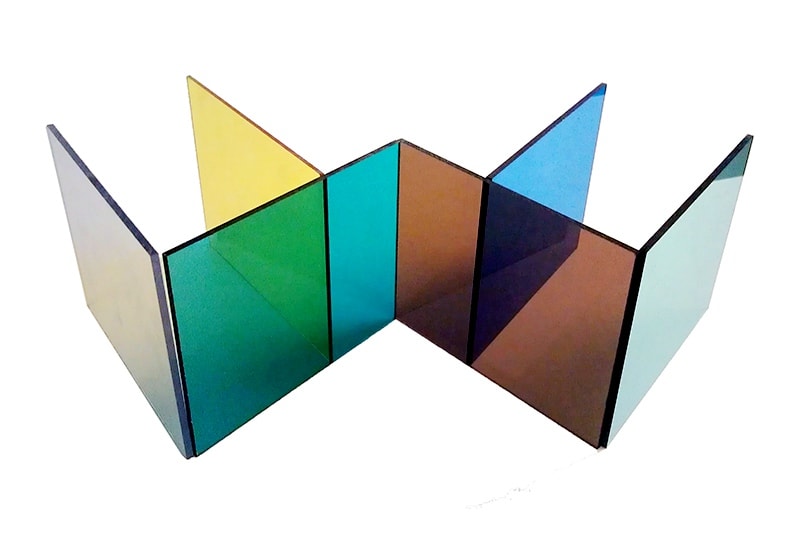

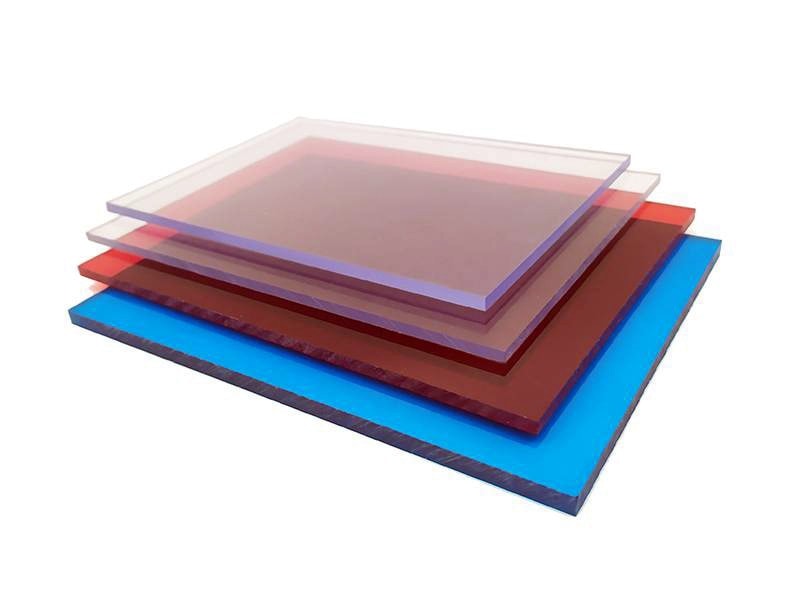

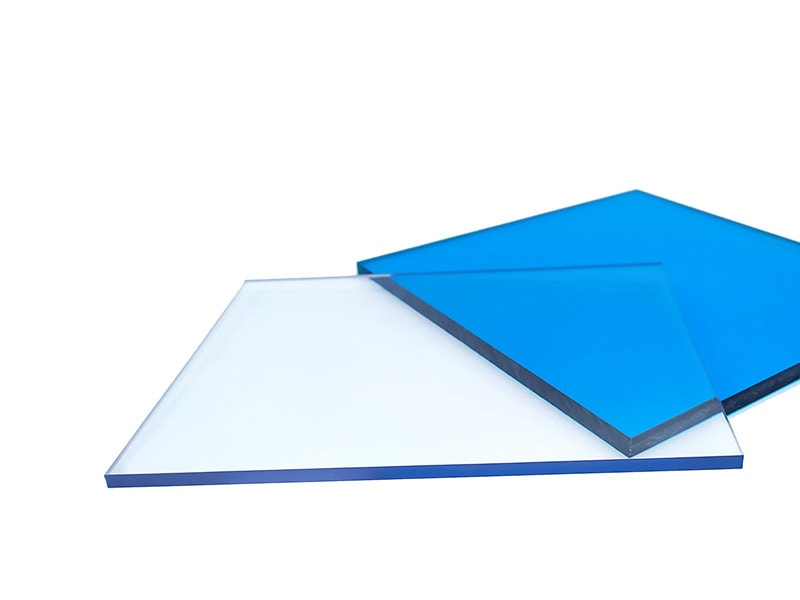

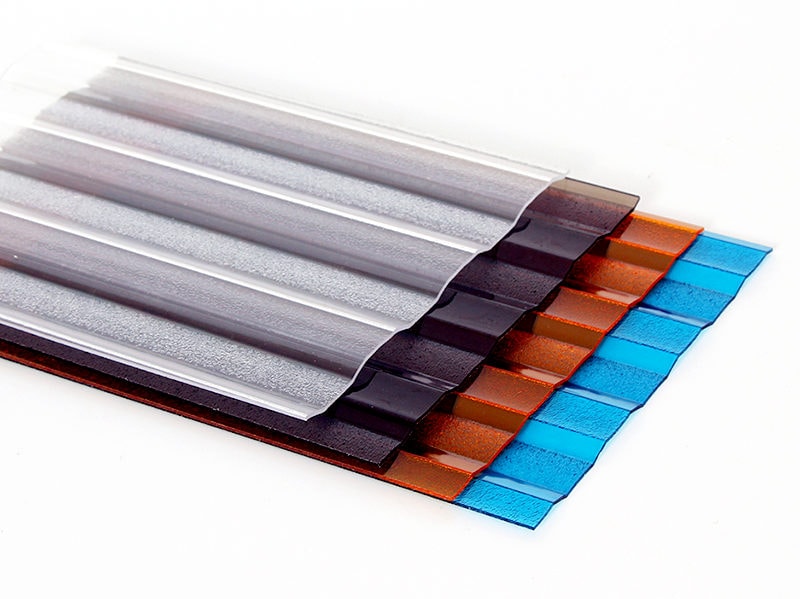

UVRPC Polycarbonate Roofing Panels offer a wide variety of color options, like clear, Bronze, Opal White, Green, Blue, etc. It offers different colors on different surfaces, such as Bronze on one side, Opal White on another side. Otherwise, it can offer a Bright Surface or a solar control function, which can block the infrared heat of sunshine, help to control the temperature in the building, meantime, it keeps the great light transmittance of the skylight roof for a more comfortable environment.

UVRPC Polycarbonate Roofing Panels are 100% leakage-proof and dustproof. With the excellent UV coating technology, UVPLASTIC coats the UV protective layer on one or two sides, therefore, the lifespan of Polycarbonate Roofing Panels is about 15 years.

UVPLASTIC™ Polycarbonate Roofing Panels Specification

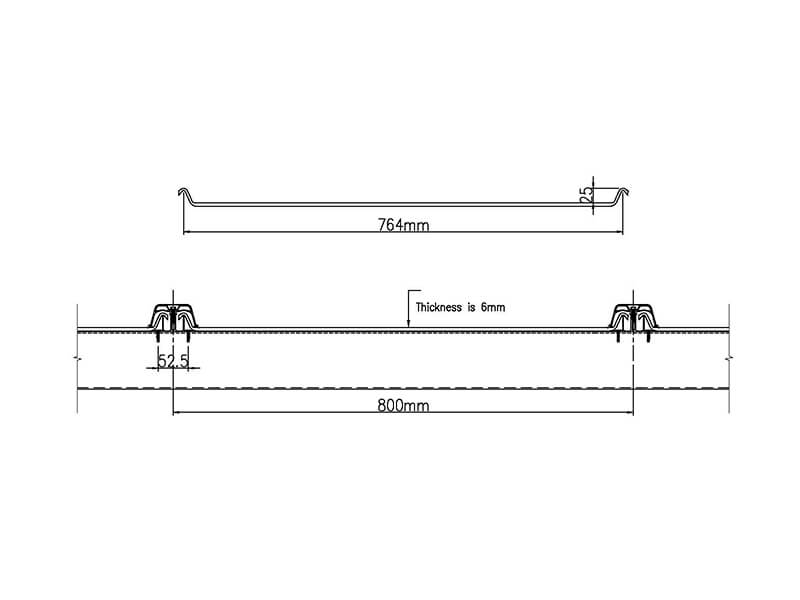

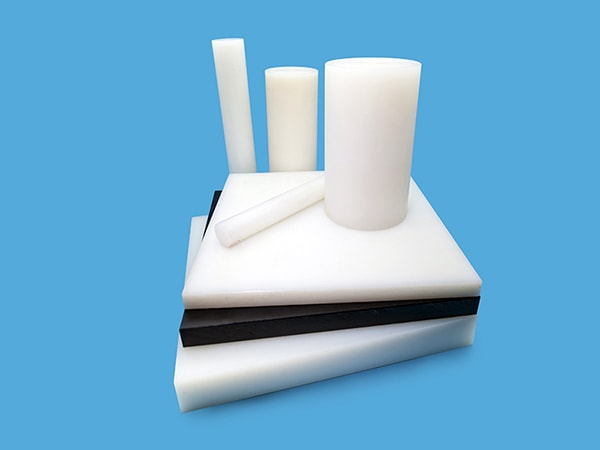

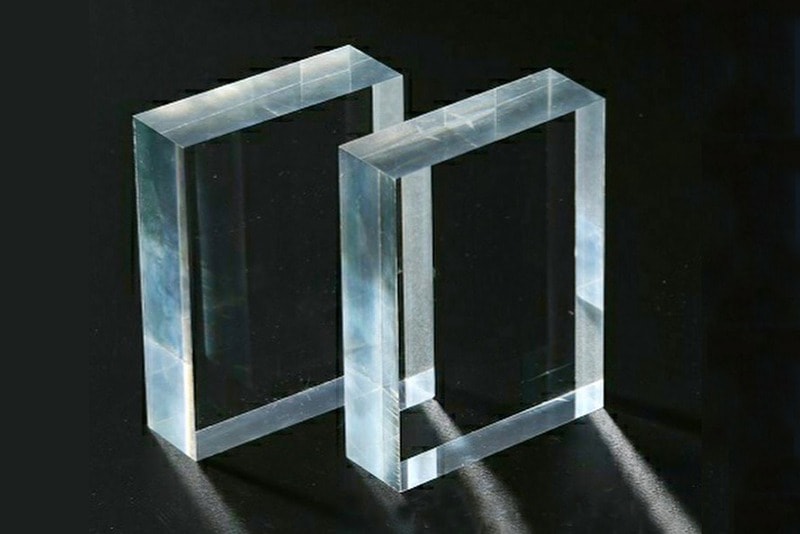

Standard Size for UVRPC Solid Polycarbonate Roofing Panel

| Product Name | Model | Width (mm) | Thickness (mm) | Weight (Kg/sqm) |

|---|---|---|---|---|

| Solid Polycarbonate Roofing Panel | UVRPC-SO-5 | 1050 | 5 | 6 |

| Solid Polycarbonate Roofing Panel | UVRPC-SO-6 | 800 | 6 | 7.2 |

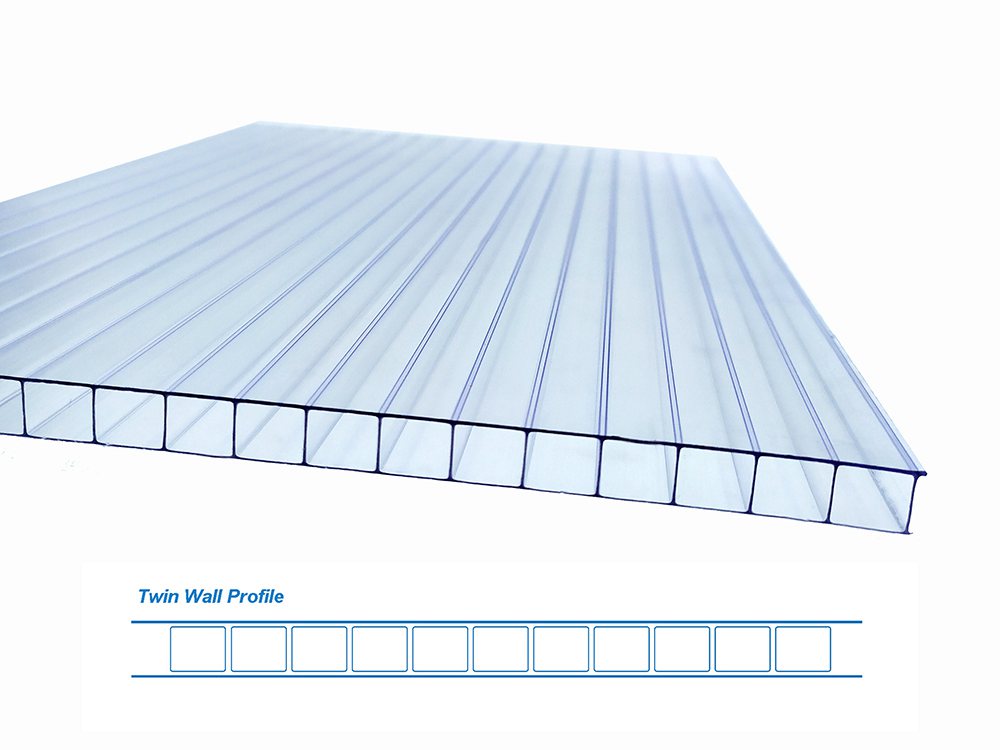

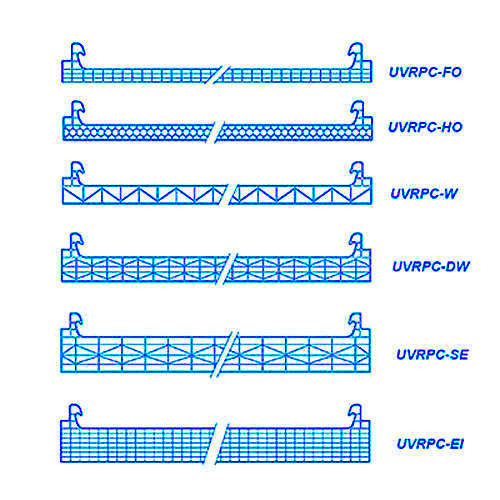

Standard Size for UVRPC Hollow Polycarbonate Roofing Panels

| Product Name | Model | Width (mm) | Thickness (mm) | U-value (W/sqm*K) |

|---|---|---|---|---|

| Four Wall Polycarbonate Roofing Panel | UVRPC-FO | 600 | 6, 8, 10 | From 2.63 to 2.41 |

| Honeycomb Polycarbonate Roofing Panel | UVRPC-HO | 600 | 8, 10, 12 | From 2.45 to 1.98 |

| W-Type Polycarbonate Roofing Panel | UVRPC-W | 700 | 8, 10, 12, 16 | From 2.63 to 2.41 |

| Double W-Type Polycarbonate Roofing Panel | UVRPC-DW | 800 | 12, 16, 18 | From 1.81 to 1.53 |

| Six Wall Polycarbonate Roofing Panel | UVRPC-SI | 600 | 10, 15, 20 | From 2.3 to 1.4 |

| Seven Wall Polycarbonate Roofing Panel | UVRPC-SE | 1040 | 16, 20, 25 | From 1.6 to 1.39 |

| Eight Wall Polycarbonate Roofing Panel | UVRPC-EI | 1040 | 16, 20 25, 30 | From 1.56 to 1.38 |

Note

UVMPC Multi Wall Polycarbonate Sheets Range

| Model | Description |

|---|---|

| UVRPC-U1 | Standard polycarbonate roofing panel with the co-extruded UV Coating Lyer on one side |

| UVRPC-U1A | The co-extruded UV protective on one side and anti-fog coating layer on another side |

| UVRPC-U2 | The co-extruded UV protection on both sides |

| UVRPC-SO | Solar control polycarbonate roofing panels |

Colors for UVRPC Polycarbonate Panels

| Item | Colors Description |

|---|---|

| Normal Colors | Clear, Bronze, Opal White, Green, Blue |

| Double Colors on Both Surfaces | Bronze/Opal White, Solar Control/Opal White |

| Solar Control Colors | Reflective grey, reflective blue, Solar Ice, Pearl, Absorbed Green, Absorbed Blue |

| Bright Surface | Clear, Bronze, Opal White, Green, Blue |

Custom colors are available subject to MOQ.

Physical Properties

| Item | Test Method | Testing Condition | Unit | Value |

|---|---|---|---|---|

| Density | D-792 | g/cm3 | 1.2 | |

| Short Term Service Temperature | °C | from -50 to +130 | ||

| Long Term Service Temperature | °C | from -40 to +100 | ||

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 | |

| Thermal Conductivity | C-177 | W/m K | 0.21 | |

| Tensile Strength at Yield | D-638 | 10 mm/min | Mpa or N/mm² | >65 |

| Tensile Strength at Break | D-638 | 10 mm/min | MPa or N/mm² | >60 |

| Elongation at Yield | D-638 | 10 mm/min. | % | 6 |

| Elongation at Break | D-638 | % | >95 | |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | MPa | 2350 |

| Flexural Strength | D-790 | 1.3 mm/min. | MPa | 100 |

| Flexural Modulus | D-790 | 1.3 mm/min. | MPa | 2600 |

Note

Default third-party testing organization is SGS;

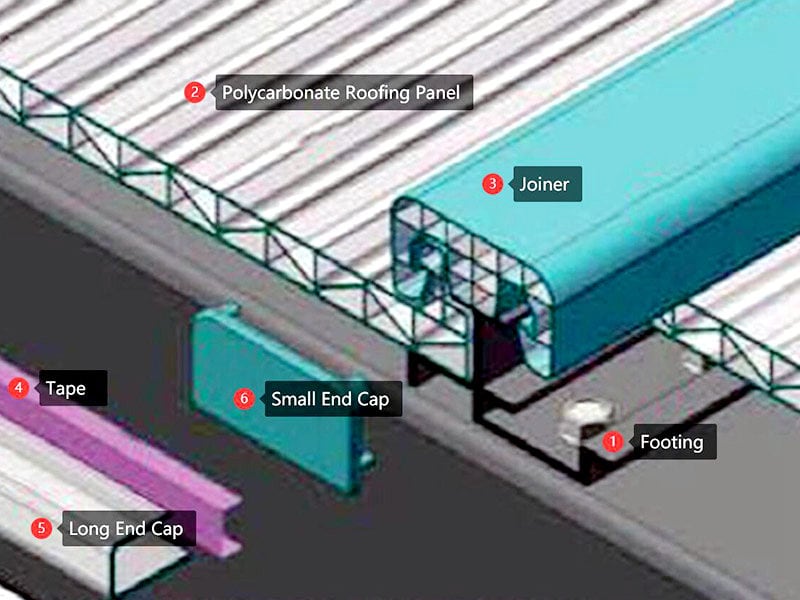

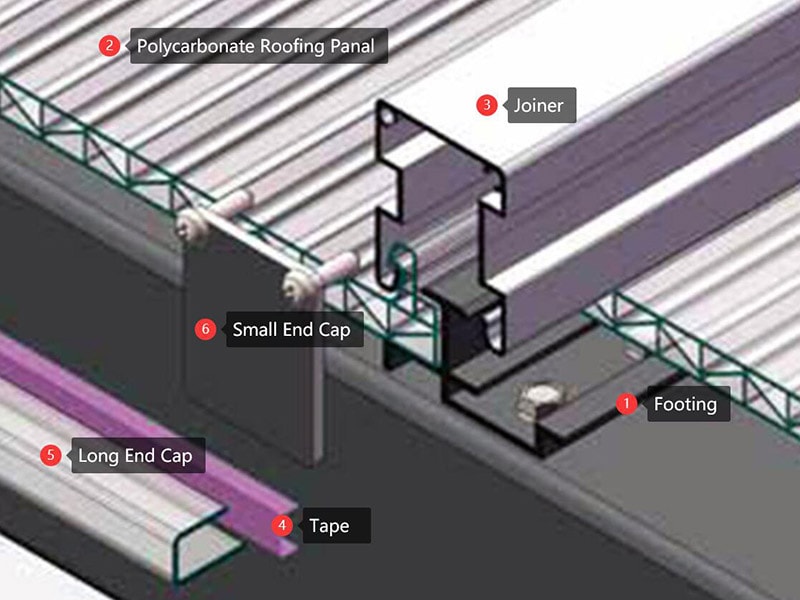

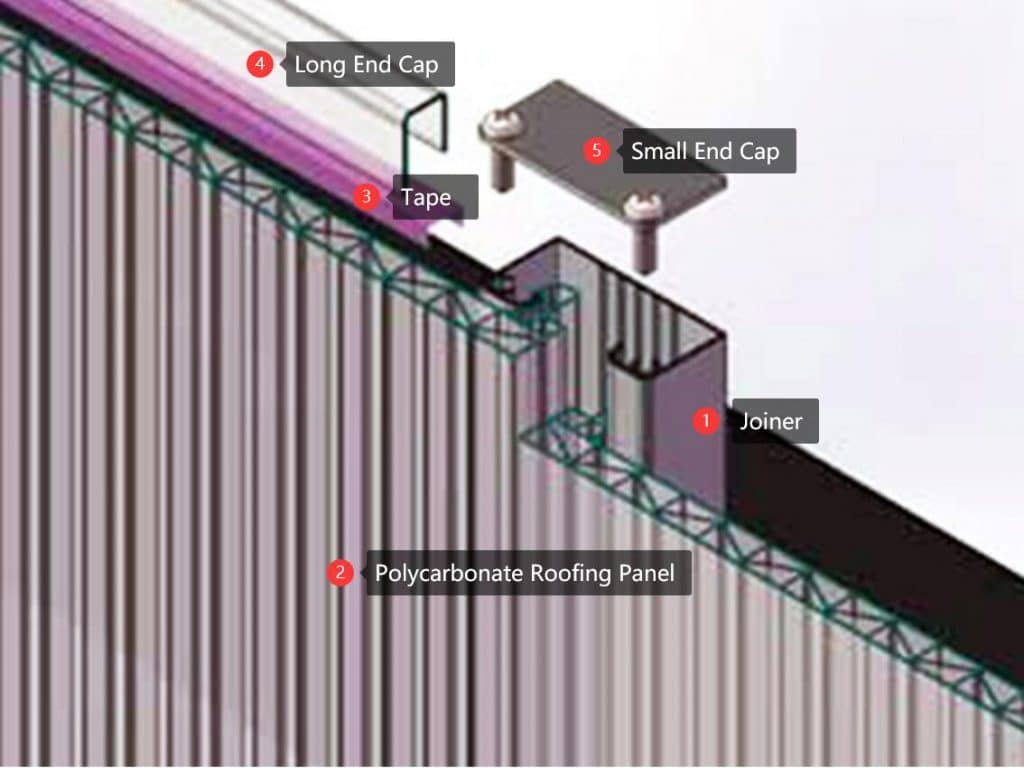

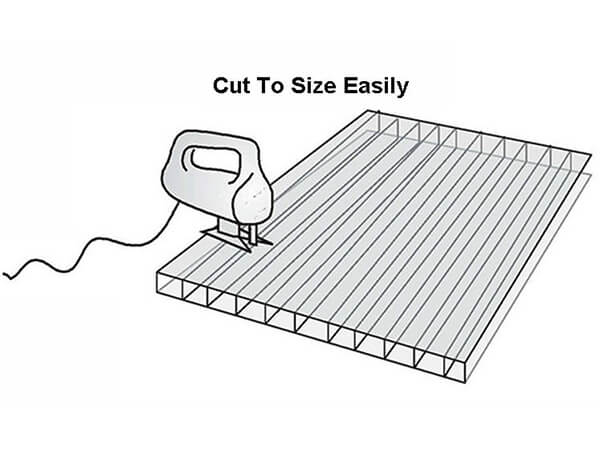

There are three installation methods for polycarbonate roofing panels, please check the following details:

- Using a screw to connect the Footing and the Joist;

- Installing Polycarbonate Roofing Panel on right position;

- Using a wooden mallet to knock on Jointer (PC);

- Adhere the Tape on the end serface of polycarbonate roofing panel;

- Install the Long End Cap (PC);

- Install the Small End Cap (PC);

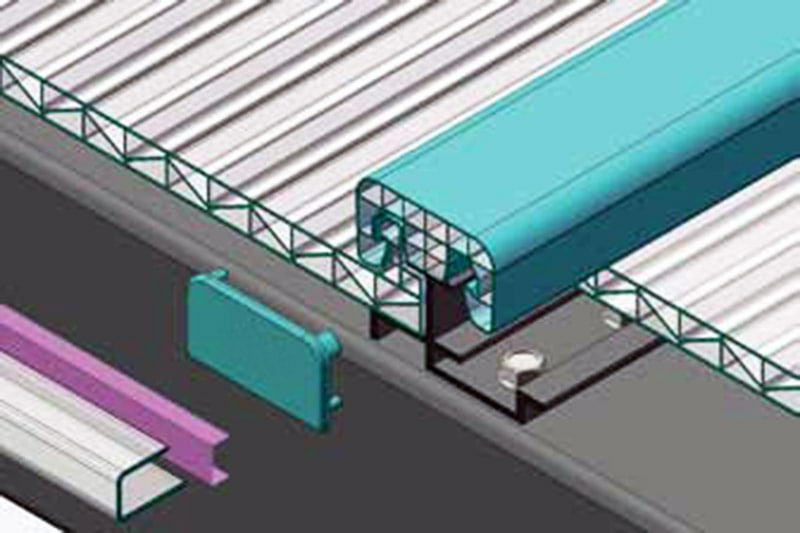

- Using a screw to connect the Footing and the Joist;

- Installing Polycarbonate Roofing Panel on right position;

- Using a wooden mallet to knock on Jointer (AL);

- Adhere the Tape on the end serface of polycarbonate roofing panel;

- Install the Long End Cap (AL);

- Install the Small End Cap (AL);

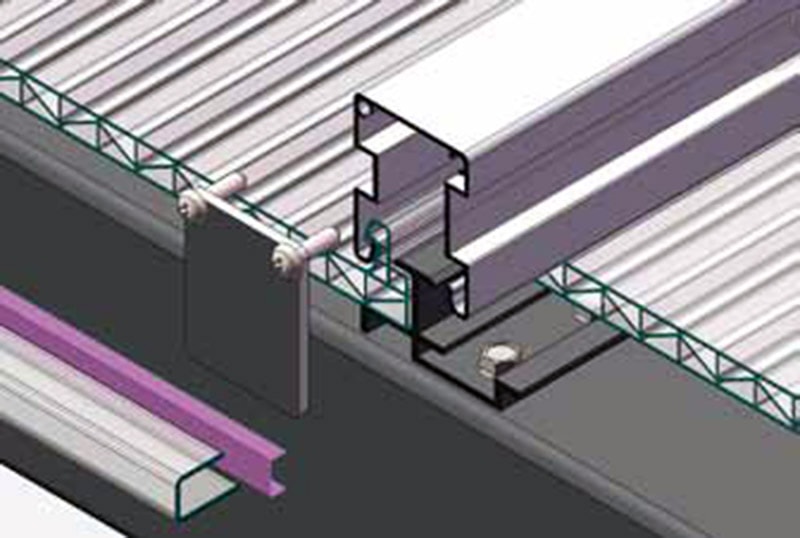

Polycarbonate Roofing Panel can be used for facade system, please see the following installation:

- Using a screw to connect the Joiner (AL) and the Joist;

- Installing Polycarbonate Roofing Panel on right position;

- Adhere the Tape on the end serface of polycarbonate roofing panel;

- Install the Long End Cap (AL);

- Install the Small End Cap (AL);

Download Catalogs

Main Benefits

UL Flammability Standard Released By Underwriters Laboratories

Part of UVRPC Polycarbonate Roofing Panel can meet the V-0, Class A/B fire rating according to UL94/ASTM E84

Restriction Of Hazardous Substances

UVPLASTIC offers environmentally-friendly polycarbonate sheets and meets RoHS and REACH

For A Fast Quotation, You Need To Tell Us The Following Information

Structure

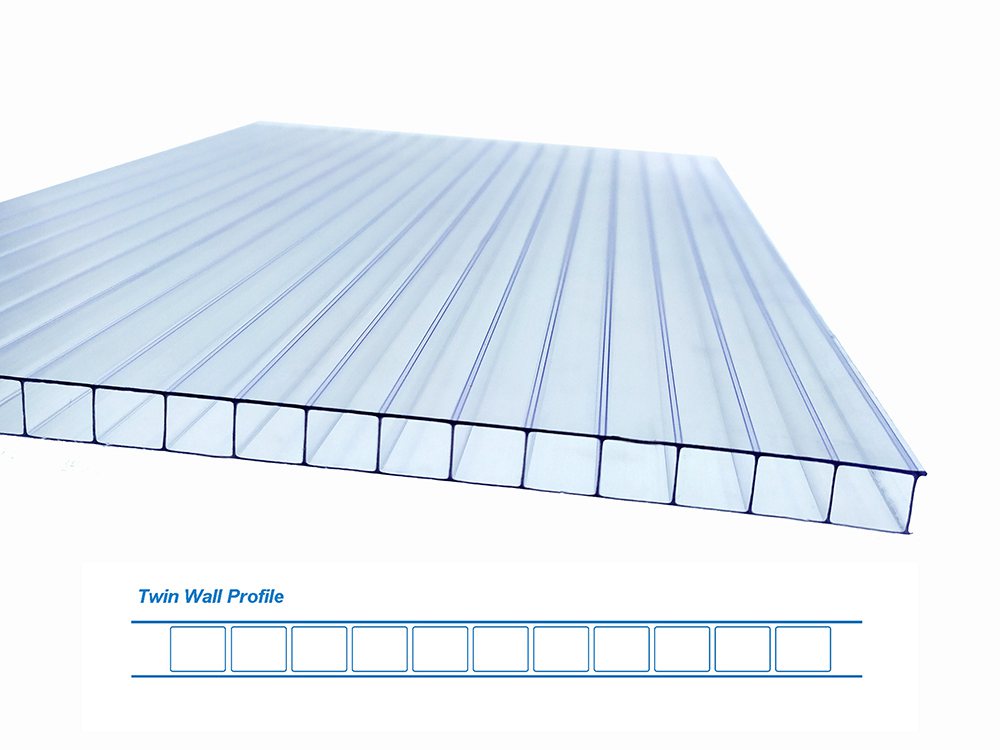

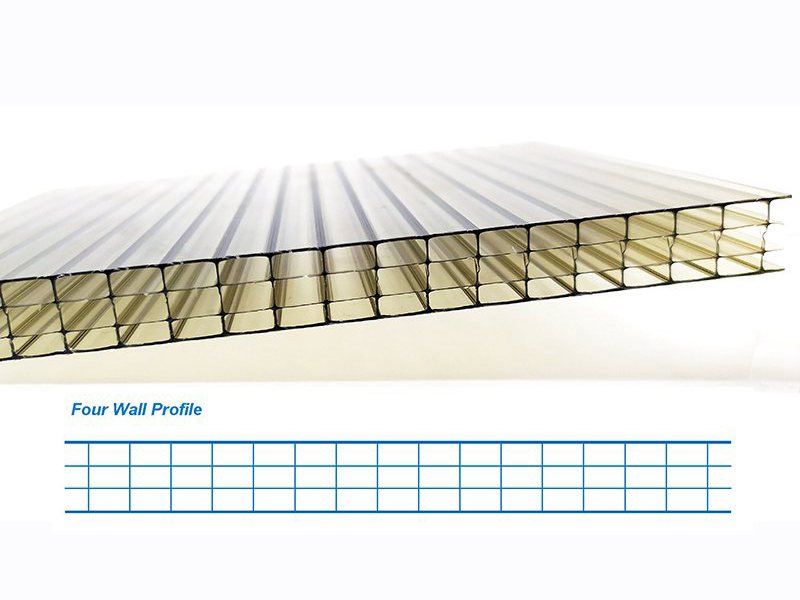

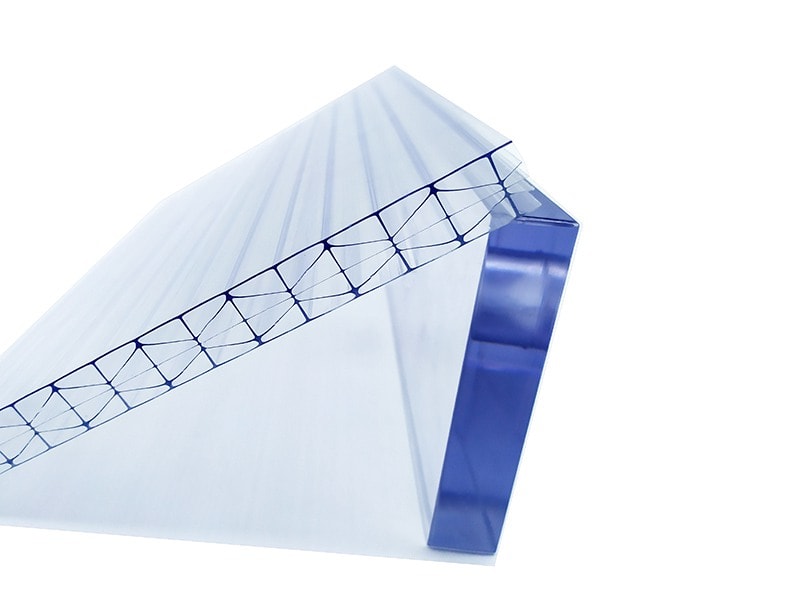

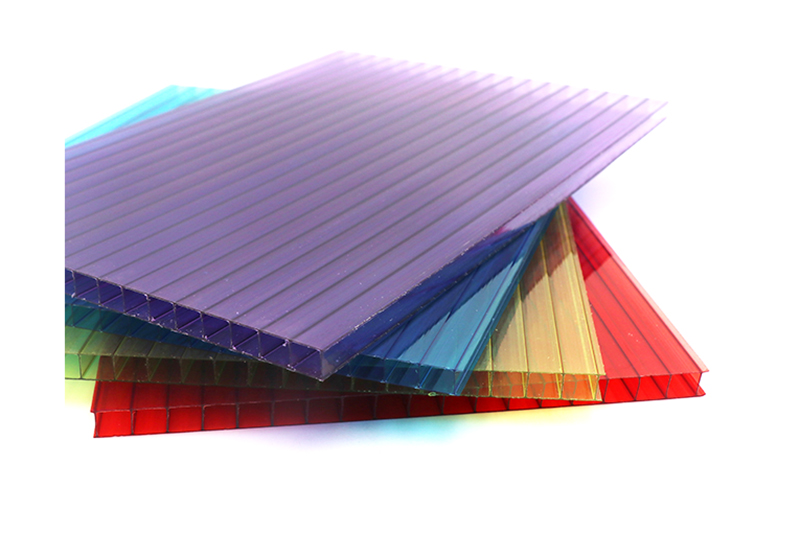

UVRPC Polycarbonate Roofing Panels offer many structures, such as Four Wall, Honeycomb Wall, W-Type Wall, Double W-Type, Seven Wall, and Eight Wall Structure, they have different widths.

Length

UVRPC Polycarbonate Roofing Panels offer standard width for each structure. The length can be customized, but we recommend the less 12m length for shipping easily. Meantime, we will submit the accessories list.

Coating Layer

The standard polycarbonate Roofing Panel has one-side UV protective layer, the client can require us to coat UV layers on both sides or UV coating layer on one side, anti-fog coating on another side for the greenhouse.

Quantity

The more quantity results in the low production cost, therefore, clients will get a better price according to quantity. We will have MOQ requirements for custom and colored polycarbonate roofing panels.

Application

Tell us your application, we have more than 15 years of experience in polycarbonate roof panels, our engineers can confirm your choice will be the best one and give more suggestions to meet your budget.