Leading Supplier of Anti-fog Polycarbonate

Best Anti-Fog Polycarbonate Sheet Supplier In China

Anti-fog Polycarbonate Sheet Introduction

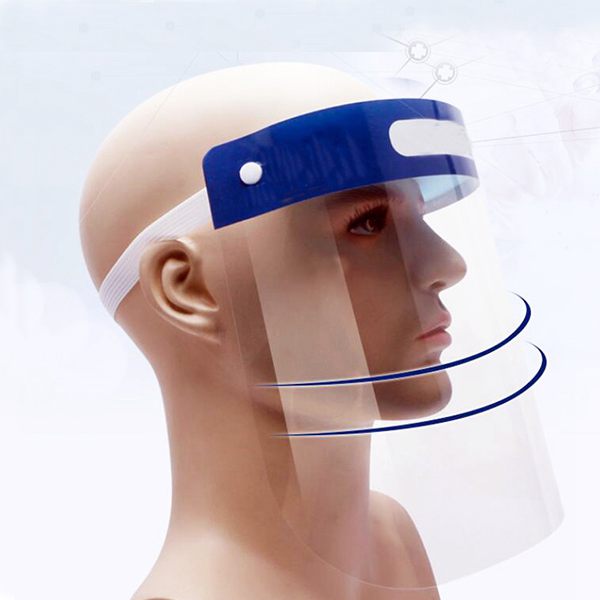

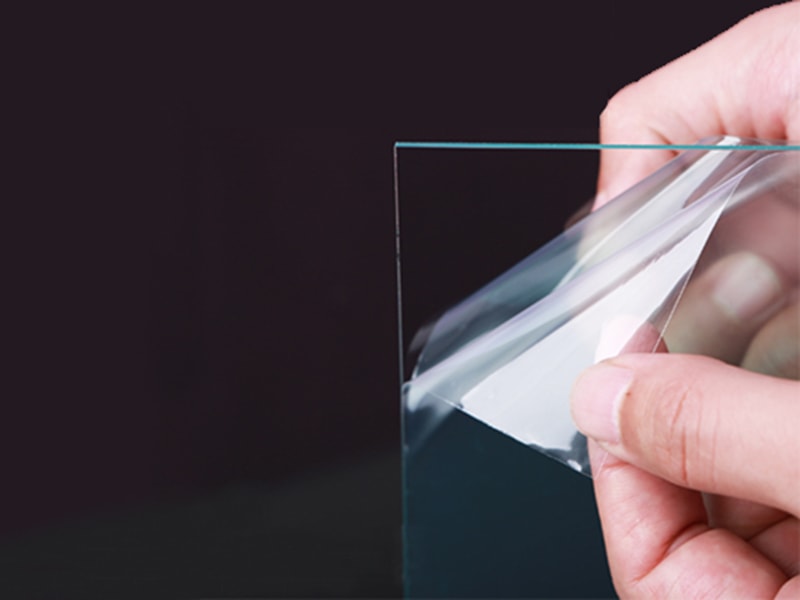

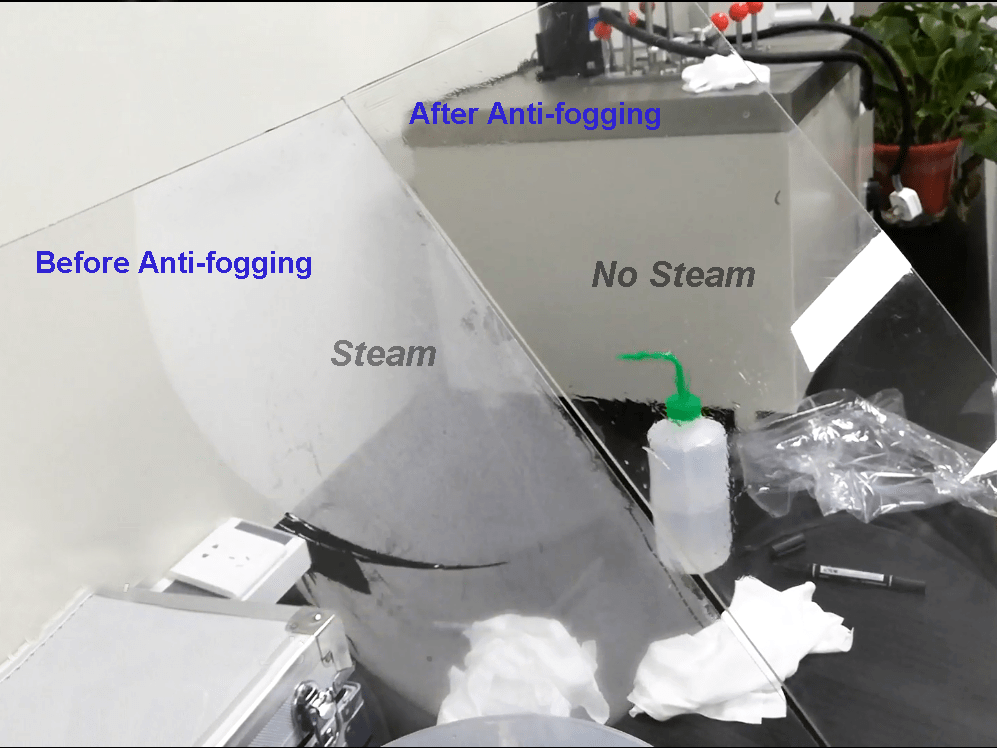

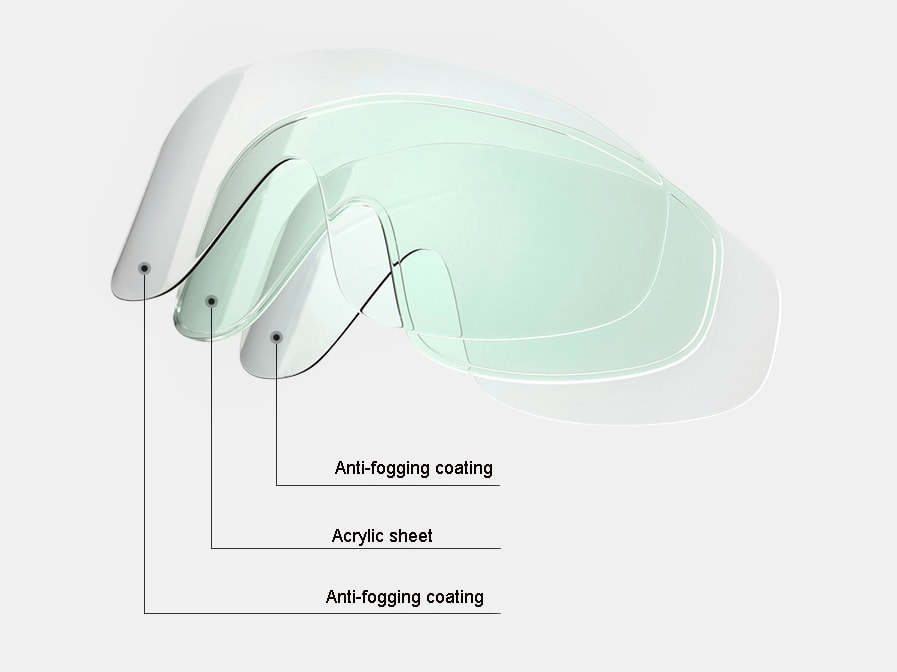

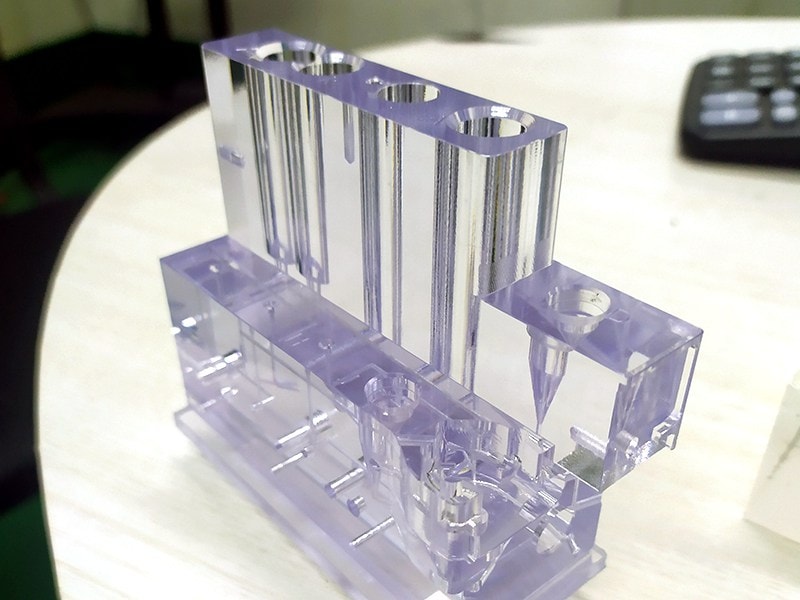

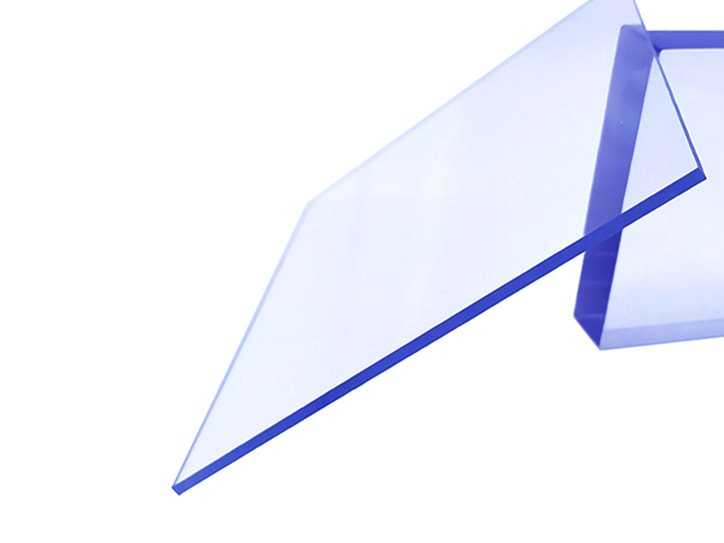

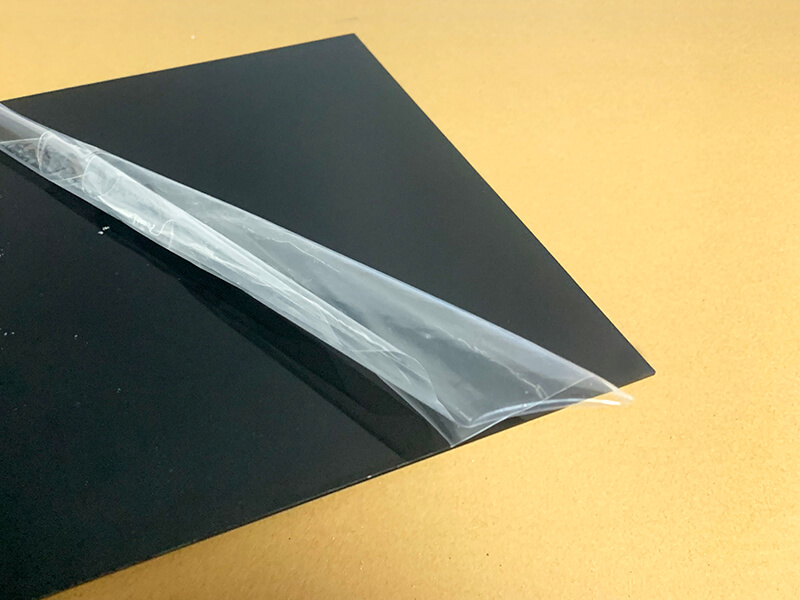

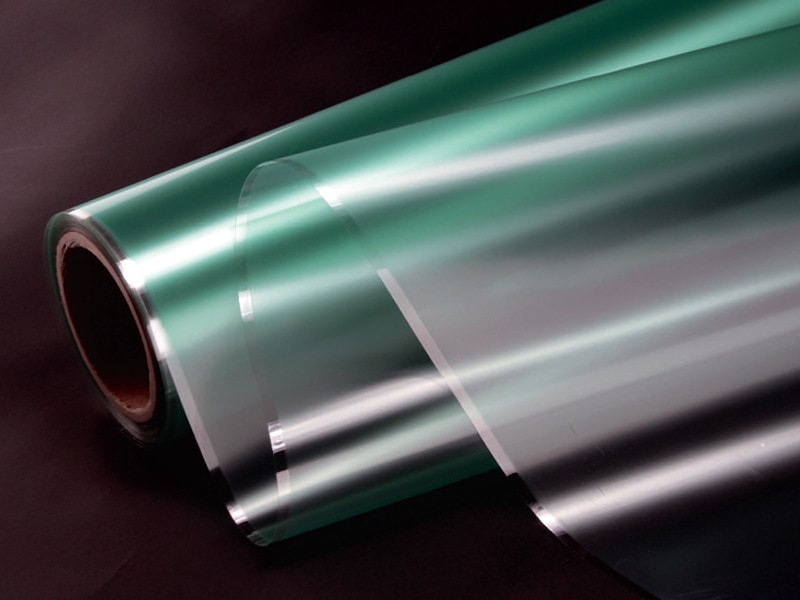

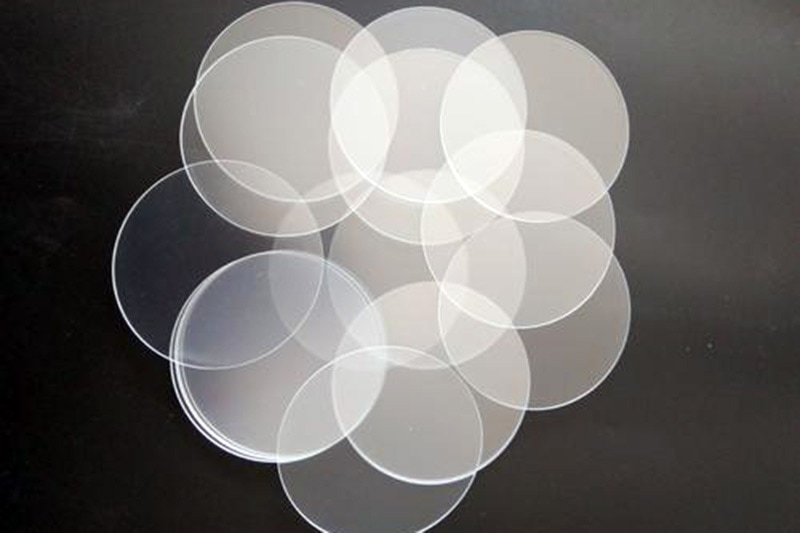

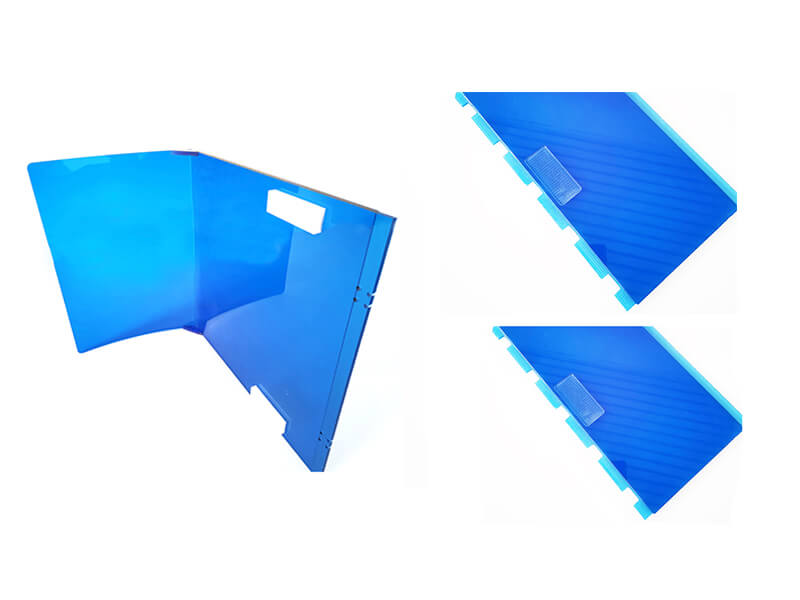

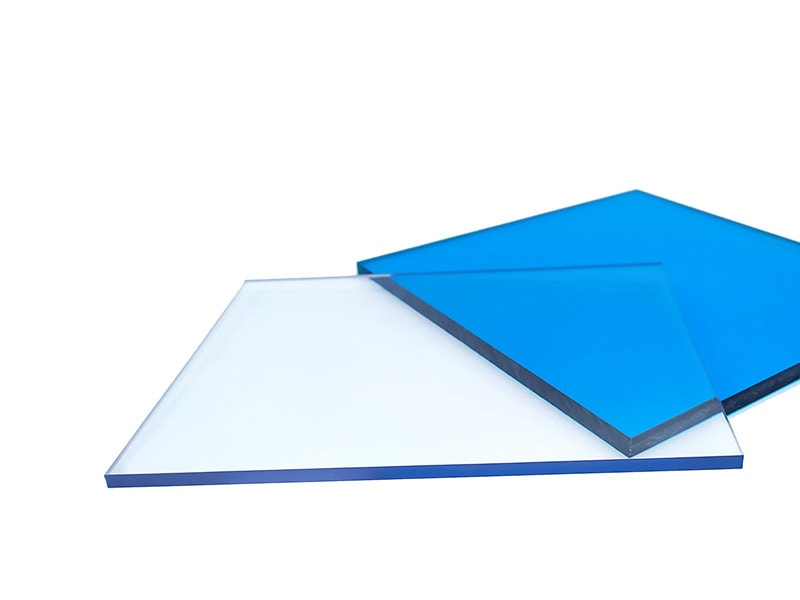

Anti-fog polycarbonate sheet is an optical grade polycarbonate, used for face masks, Snorkel masks, and helmet visors. It is coated with anti-fog coating, which is high-quality hydrophilic material on both sides, therefore it offers excellent anti-fogging properties and excellent anti-scratch performance, and superior water films for optimum clarity under high humidity conditions, even water.

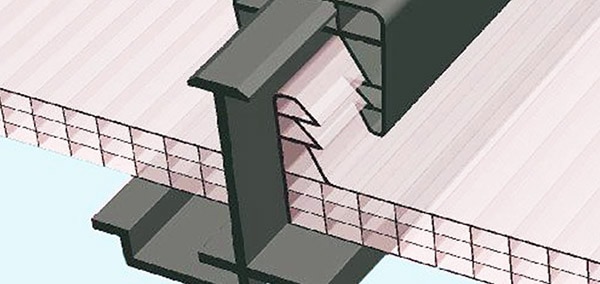

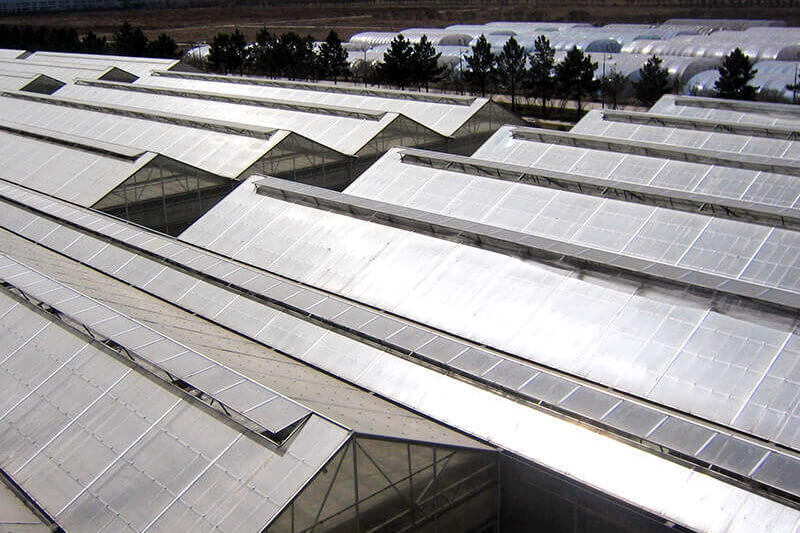

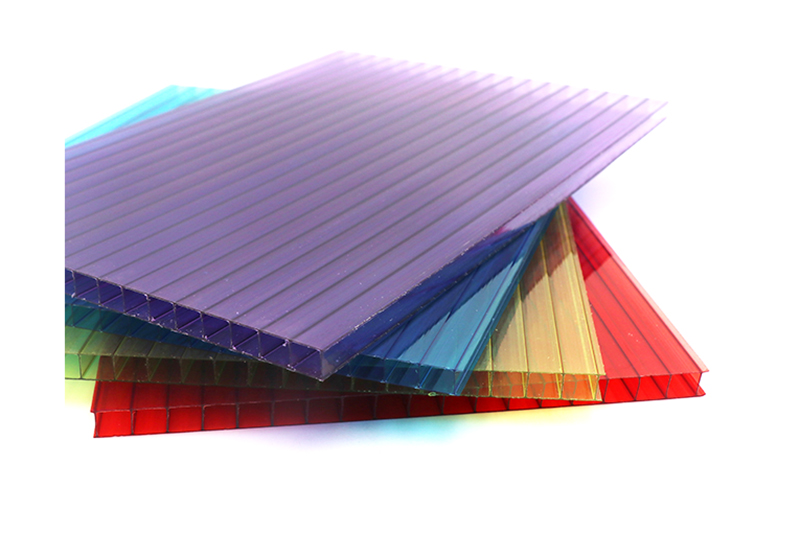

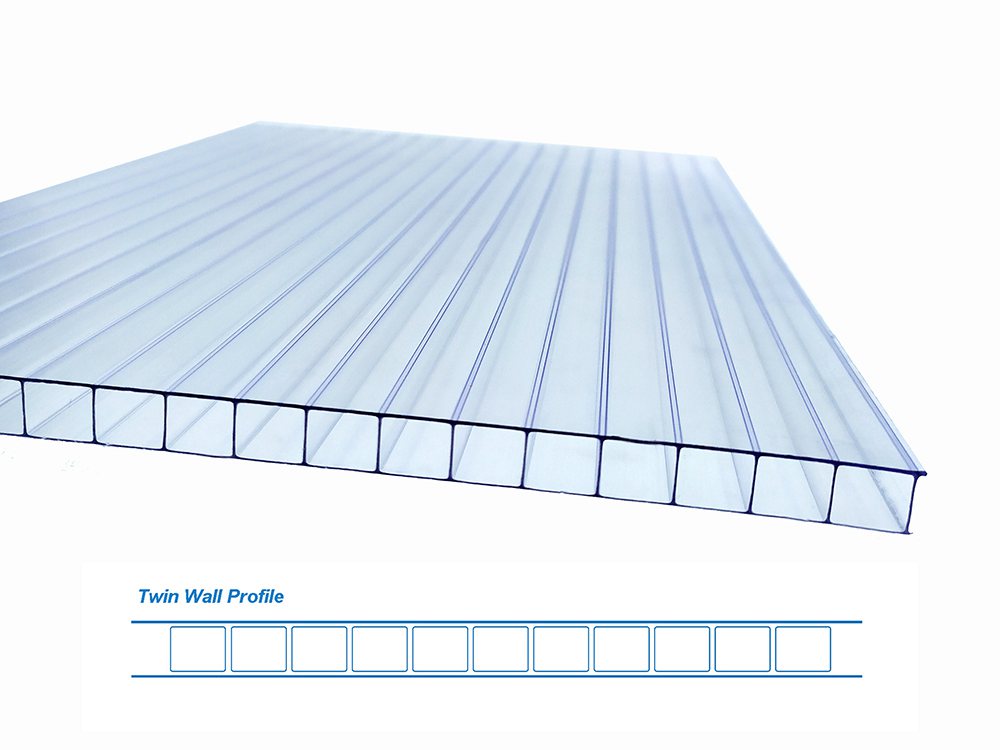

UVFPC-AF is the family code of UVPLASTIC anti-fog polycarbonate sheet, the thickness is from 0.125mm to 14mm. It is the right material for visual applications, such as medical face shield, eye shields, safety face shields, ski goggles lenses, racing goggles lens, UV face shield, sanitary mask, polycarbonate lenses, gear masks, and more. Otherwise, the anti-fog coating can be used for a multiwall polycarbonate sheet for greenhouse applications.

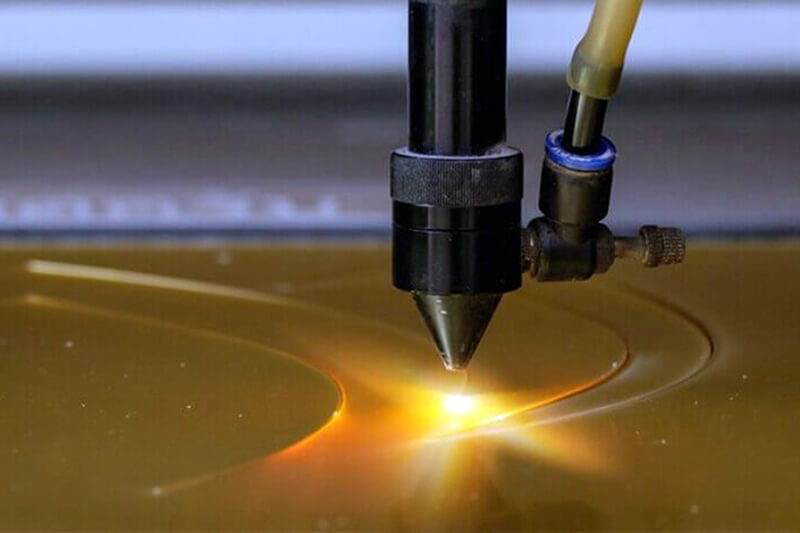

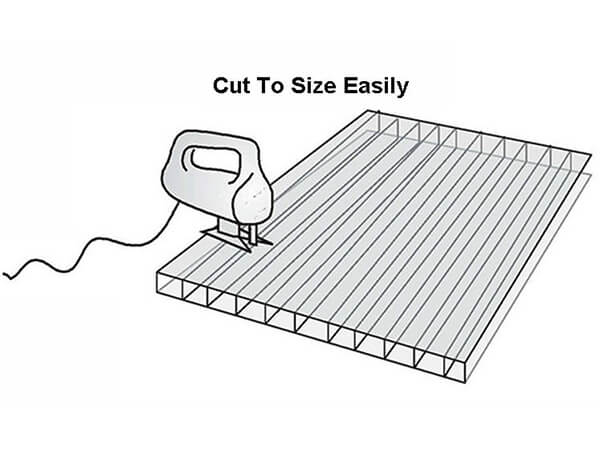

UVPLASTIC began to provide anti-fog polycarbonate sheets in 2010. By now, we have grown to be a leading supplier in China. What we can provide is not only standard anti-fog polycarbonate but also machining service according to client’s requirements.

Anti-Fog Polycarbonate Specification

UVPLASTIC Products Range

| Model | Description |

|---|---|

| UVFPC-AFE | Standard anti-fog polycarbonate, the lifespan is more than 2 years, only used as flat panel; |

| UVFPC-AFD | Durable anti-fog polycarbonate, the lifespan is more than 5 years. It can be bent to an arc-shaped panel by thermal forming, and used at a lower temperature. |

Standard Model and Size

| Item | Model | Thickness | Width | Length |

|---|---|---|---|---|

| Anti-fog polycarbonate sheet | UVFPC-AFE/D-(Thickness) | From 0.25mm to 0.5mm | 930mm, 1220mm | 1830, 2440mm |

| Anti-fog polycarbonate sheet | UVFPC-AFE/D-(Thickness) | From 0.6mm to 1mm | 915mm, 930mm | 1830mm, 2440mm |

| Anti-fog polycarbonate sheet | UVFPC-AFE/D-(Thickness) | From 1.5mm to 14mm | 1220mm | 2440mm |

Note: UVPLASTIC provides anti-fogging polycarbonate sheets with custom sizes and custom shapes.

Physical Properties of anti-fog polycarbonate sheets

| Property | Testing Method | Testing condition | Unit | Value |

|---|---|---|---|---|

| Density | D-792 | g/cm3 | 1.2 | |

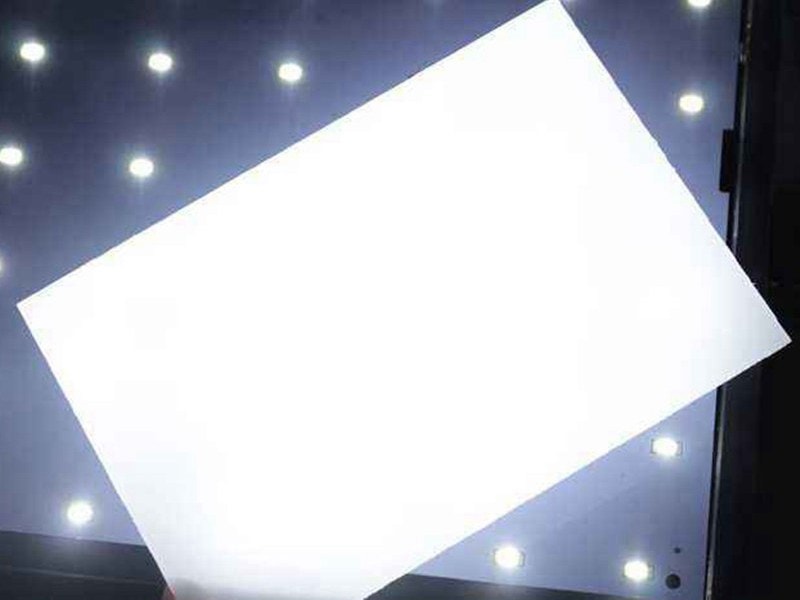

| Light Transmission | D-1003 | % | 82 – 92 | |

| Haze | D-1003 | % | <0.5 | |

| Fog Free time | s | >22 | ||

| Surface Hardness | From HB to 1H | |||

| Long Time Service Temperature | °C | from -40 to +100 | ||

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 | |

| Thermal Conductivity | C-177 | W/m K | 0.21 | |

| Tensile Strength at Yield | D-638 | 10 mm/min | Mpa or N/mm² | >65 |

| Tensile Strength at Break | D-638 | 10 mm/min | MPa or N/mm² | >60 |

| Elongation at Yield | D-638 | 10 mm/min. | % | 6 |

| Elongation at Break | D-638 | % | >95 | |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | MPa | 2350 |

| Flexural Strength | D-790 | 1.3 mm/min. | MPa | 100 |

| Flexural Modulus | D-790 | 1.3 mm/min. | MPa | 2600 |

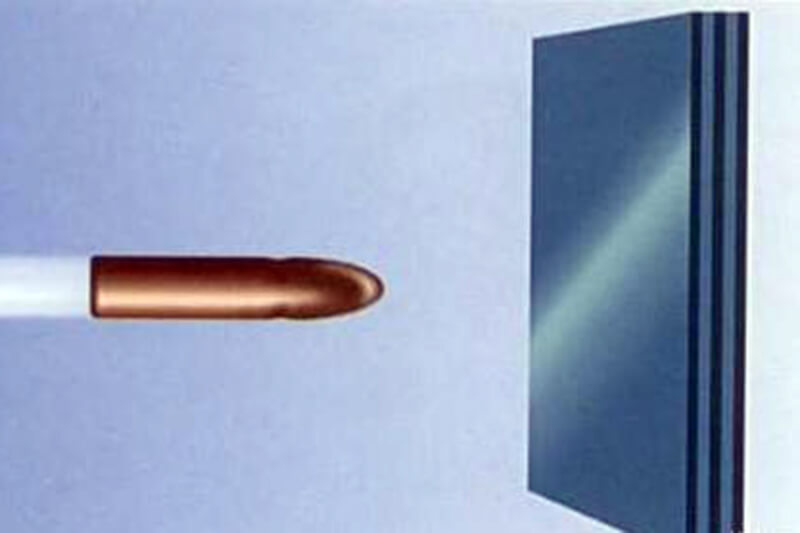

| Impact Falling Weight | ISO 6603/1 E50 | 3mm sheet | J | 158 |

The default third-party testing organization is SGS;

Typic applications

Main Benefits

Coating service for polycarbonate sheet

For some applications, like snorkel masks, windshields, industrial clean rooms, face masks, etc, normal polycarbonate sheets can’t meet the requirements. Therefore, UVPLASTIC will coat the special layers on the one-side or two-side surface:

| No. | Coating Service | Description |

|---|---|---|

| 1 | Anti-static/ESD Coating | The surface resistance of polycarbonate from 10E5 to 10E8 Ohm, for industrial cleanroom, dust-free room. |

| 2 | Hard Coating | Increase the surface hardness for 2-6 levels than the general-purpose polycarbonate sheets. |

| 3 | Non-glare Coating | Minimize glare and reflection with a matte finish, it creates a glare-free view from any angle. |