Polypropylene (PP) vs Polycarbonate (PC): Honest Comparison

If you’re a frequent reader of our blog, you’ve probably seen our last blog, where we published a head-to-head comparison between polycarbonate sheets and ABS plastic. Today, we’ll do the same with polypropylene plastic.

Before we jump into the comparison, first let me introduce you to this widely used material. It’s a thermoplastic polymer made by chain-growth polymerization. This is one of the most used plastic materials in today’s world. To know everything about polycarbonate.

With the increasing number of new plastic grades and materials, you can easily get confused while shopping for plastic materials. This is the reason we’re publishing these guides: to help our readers understand which is what and make a better decision for themselves. Want to know how to identify Polycarbonate sheet?

Let’s dive into the comparison now.

Impact Resistance and Strength

When it comes to impact resistance and strength, you already know polycarbonate wins by large. It’s one of the most robust types of plastic material and offers superior strength and the longest lifespan.

On the other hand, polypropylene is a durable product as well. Offers great impact resistance than many other materials, although it isn’t as strong as PC plastic.

Weight

We all want lighter products for ourselves. One of the reasons polycarbonate is so widely used as an alternative to glass and metal is that it’s lighter than these.

If we compare the weight of PC and PP materials, PP is much lighter than PC materials. And that makes it a great choice for many applications, including luggage and suitcases. To know Polycarbonate Luggage.

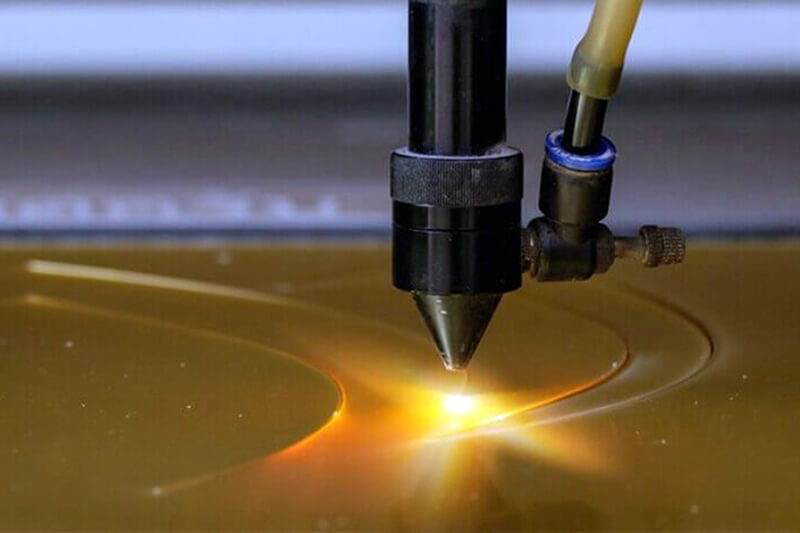

Machinability

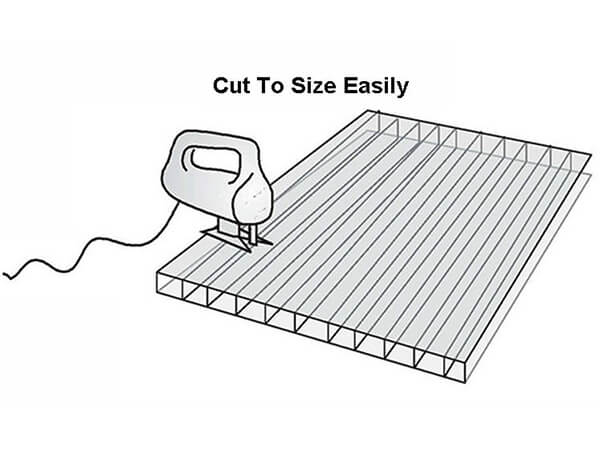

If you need plastic material for machining, you’ll want to avoid polycarbonate plastic. Because it has an optimum level of strength, PC materials cannot be machined properly. You should have good skills in machining polycarbonate.

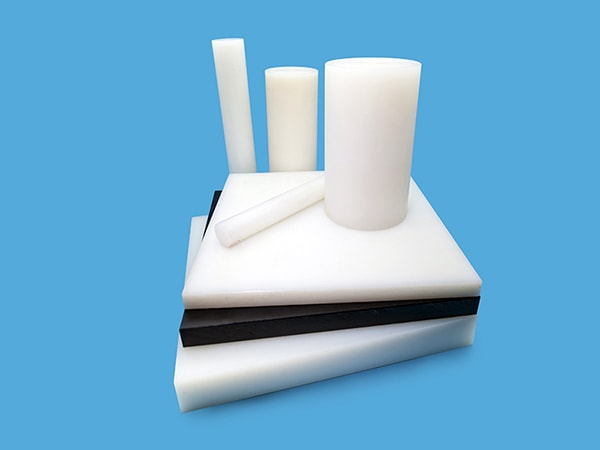

Manufacturers can use polypropylene materials for machining because it’s easy to machine and shaped into.

Applications of these materials

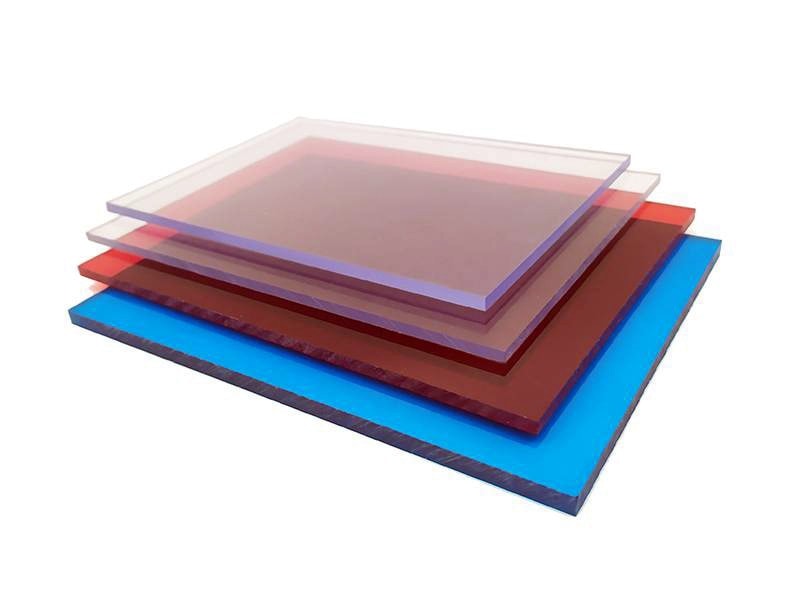

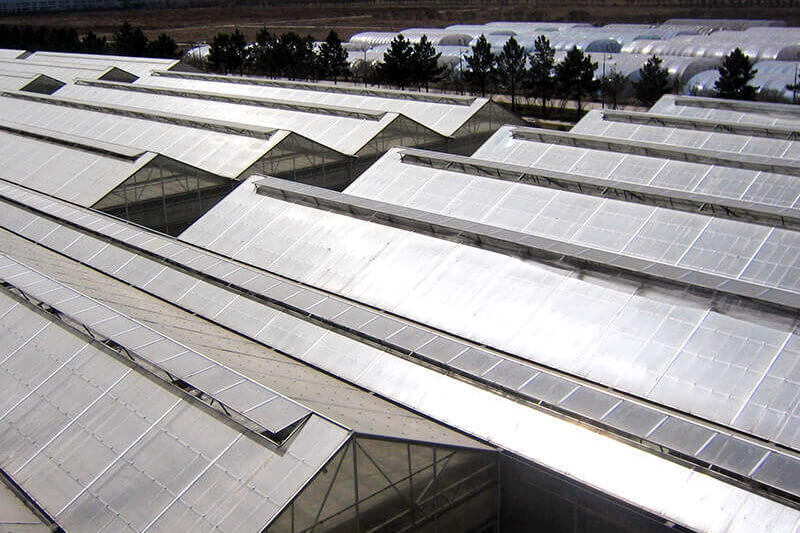

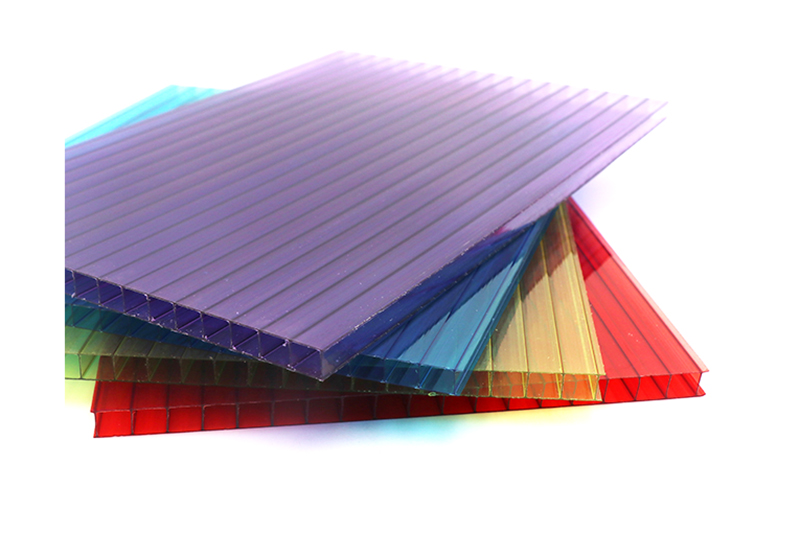

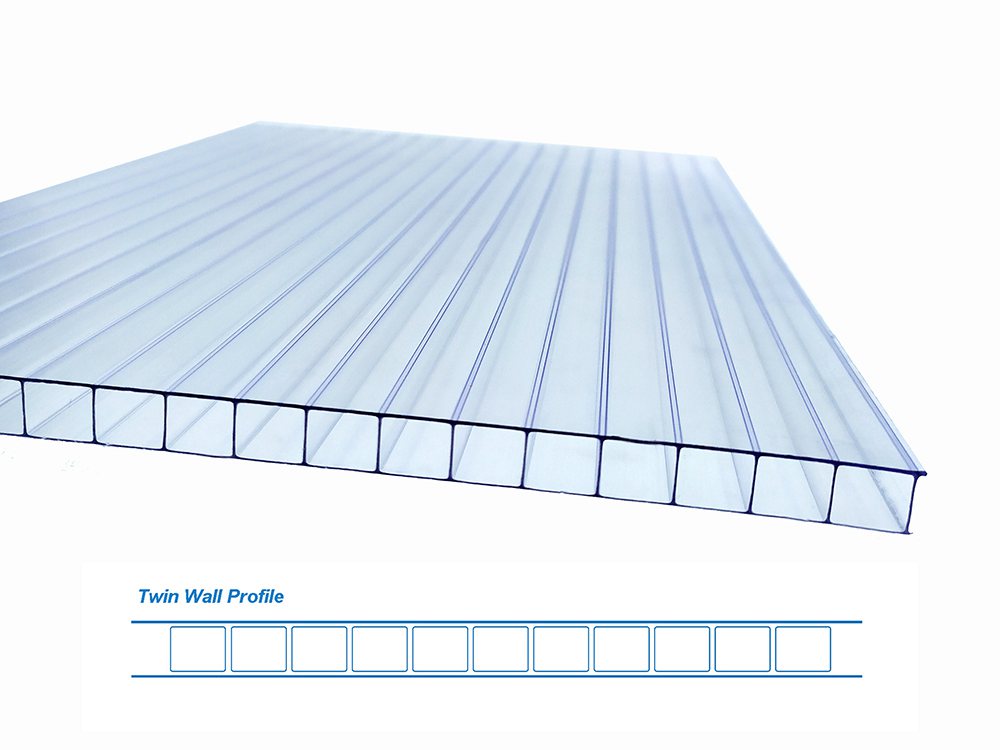

Polycarbonate and Polypropylene both have a wide range of applications. However, PC materials are mostly used for heavy-duty uses, such as greenhouses, roofing panels, riot shields, protective walls, etc. Because they don’t break and are highly impact-resistant while offering extremely good transparency and lightweight ability, polycarbonate can be used as an alternative for both metal and glass materials.

On the other hand, polypropylene offers a great deal of value too. You can’t use it for greenhouses, but that doesn’t eliminate the wide range of applications of this product. It was one of the most produced plastics in 2019, and the consumption of this material is going up every year.

PP plastic is mostly used for packaging, car and medical equipment, bags, disposable items, etc. Among those, this material is one of the best packaging materials. We use it every day from our bottle caps to shopping bags.

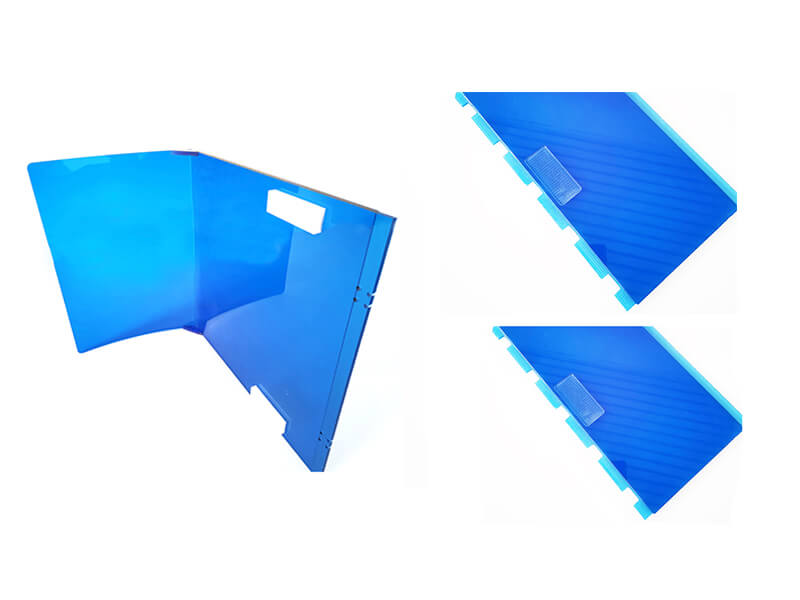

PC Luggage Vs PP Luggage

Yes, that’s right. Polypropylene luggage is also widely used, in addition to Polycarbonate and ABS luggage. The best thing about this is that it falls in the middle of the other two alternatives.

When we consider durability, strength, and lifespan, Polycarbonate Luggage is the clear winner of these three alternatives. On the other hand, ABS Plastic comes last in those criteria. Here to know the difference between ABS and Polycarbonate.

If you want something in the middle, PP luggage can be the best option for you. With a modest price, you get decent durability and strength.

Also, the price of polypropylene falls in between these two alternatives. When you’re on a budget, you should go with the ABS luggage, and when you need something exceptional, polycarbonate is the right one. And if you need something that has a fair strength, high durability and the price is moderate, Polypropylene is the right choice for you.

The best part about polypropylene luggage is that, although it’s more strong and durable than ABS, it’s the lightest of all. If you often travel by air, you’ll love to have light luggage like this that offers excellent durability and strength.

Which one is for you?

No question that polypropylene is a great plastic material. But it’s mostly used for consumer products and packaging. It’s mostly used for mass production. When you need a durable plastic material for your own use or application, you probably need either a polycarbonate or acrylic sheet.

EndNote

I really hope you got some valuable info from this guide. But your job isn’t over. If you really think this guide helped you in any way. Make sure you share it with your social media profile. And if you have any questions about these products you can contact us directly with our chat option and email.

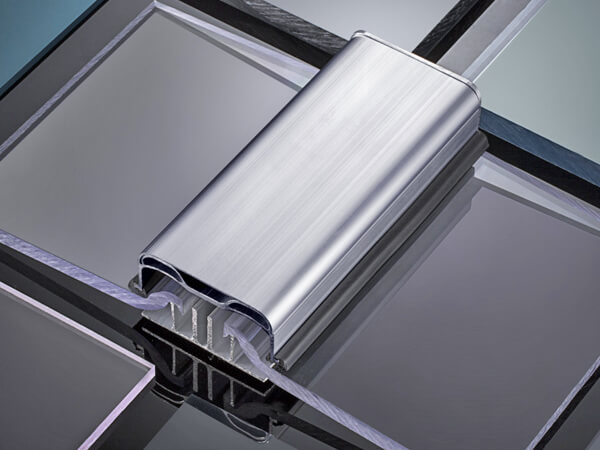

If you need polycarbonate materials directly from China, feel free to contact us. We supply polycarbonate and acrylic plastic worldwide. When you order from UVPLASTIC, you get the best products at a fair price. Our production facility enables us to deliver the highest quality products in a short lead time.

About UVPLASTIC

UVPLASTIC is a leading manufacturer of polycarbonate in China. It also provides a design and machining service for polycarbonate. The subsidiary UVACRYLIC, a leading manufacturer of acrylic sheets in China, provides custom acrylic. If you are interested in these products, please get in touch with us!