Understanding IR Transmission in Polycarbonate

Wondering if infrared (IR) light can penetrate polycarbonate? Discover the fascinating answer and its implications for various applications in this engaging read.

You cannot detect the passing of infrared radiation, but most likely, you can feel the heat if the IR touches your screen. On the other hand, considering the second element of the article’s title, polycarbonate is a very important thermoplastic.

It is transparent and used in various products like eyewear lenses, bulletproof glass, greenhouse panels, etc. Therefore, you cannot deny the importance of polycarbonate, which is used in producing products for households and defense departments. So, knowing whether IR can pass through polycarbonate is crucial.

The direct answer is a ‘yes.’ But this one-word answer is not sufficient for all. Knowing the answer in detail is essential as it can enable numerous opportunities to optimize many devices and systems. Let’s find out the answer together.

Why You Should Know Whether IR Pass through Polycarbonate or Not

Several reasons demand an answer to the question of whether IR can pass through Polycarbonate or polycarbonate-made products.

For Expert Knowledge

First, a considerable amount of polycarbonate is used as construction material, and some of it needs to interact with IR. So, the respective industry professionals must know whether IR passes through polycarbonate.

For Product Design

Second, in the case of product design in the electronics, automotive, construction, etc. industries, the respective answer is vital to developing an effective and valuable product design with a decision – the designed product will or will not host polycarbonate as a construction material.

For the Right Material Selection

Considering the IR transmission properties in some critical applications, such as greenhouse construction, solar panel production and installation, and optical component manufacturing, the answer to whether IR can pass through Polycarbonate is essential. The reason is that the right product selection matters a lot.

For Security and Surveillance

Understanding the interaction process between IR and Polycarbonate is crucial in the security and surveillance sector. Understanding the interaction results in a higher outcome of using IR in security and surveillance equipment.

For Scientific Research

In the case of material, atmospheric, and medical science, studying IR transmission through polycarbonate is highly important. The associated knowledge is used in inventing new products and systems.

Basics of Polycarbonate

Polycarbonate (PC) is one of the most popular plastics in the polyester family. Bisphenol A and carbonyl chloride polymerization occur during its production process.

Finally, the solidifying, cooling, and finishing processes take place to get usable polycarbonate. The final outcome is the ready-to-use polycarbonate combining the properties of plastics with the properties of glass.

Characteristics of Polycarbonate

The points listed below inform you of the characteristics of the material considered.

Most Common Applications of Polycarbonate

The following are the most common applications of polycarbonate.

Understanding Infrared Light

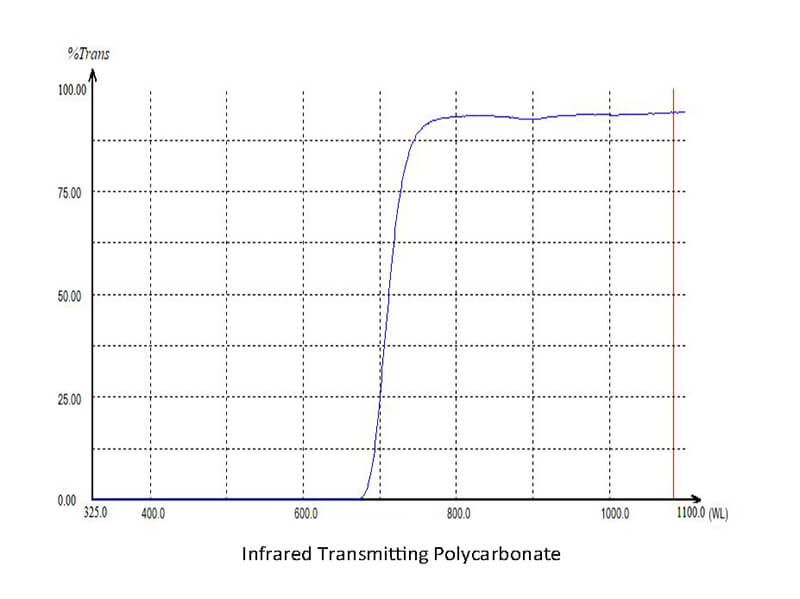

Infrared light is a specialized type of electromagnetic radiation. Its wavelengths range from 700 nanometers to 1 millimeter. Based on the wavelengths, this light is categorized into three parts: near-infrared, mid-infrared, and far-infrared.

Base Characteristics of IR

The characteristics are listed below.

Most Common Applications of IR

The following are the uses of IR.

Examining Interaction between Polycarbonate and IR

Even though polycarbonate allows the passing of 99% visible light, the passing of IR through any polycarbonate-made product or polycarbonate sheet is a bit complex. However, the answer to the core question of this article is that IR can pass through polycarbonate.

Still, various factors are integrated into this interaction process in which IR passes through polycarbonate.

The first factor is the wavelength of the IR. Polycarbonate allows passing near-infrared radiation with wavelengths of 700 to 1500 nanometers, approximately 100%.

But, the result is different in the case of mid-infrared with 1,500 nanometers to 3,000 nanometers wavelengths and far-infrared radiation with wavelengths of 3,000 nanometers to 1 mm.

For these two types of infrared radiation, the respective polycarbonate sheet or polycarbonate-made product absorbs most of the IR and increases the heat of the respective polycarbonate item.

Conclusion

We hope that you now have an in-depth answer to can IR pass through polycarbonate. Now, you know that near-infrared allows almost 100% passage of IR. However, the mid-infrared and far-infrared radiations encounter absorption of some portion by the polycarbonate sheet or the component used in polycarbonate-made products.

Finally, we suggest that industry professionals and scientists do more research to use the interaction between IR and polycarbonate more effectively to find new opportunities, equipment, etc.

UVPLASTIC is a leading supplier of IR-transmitting polycarbonate in China, and it offers machining services. Contact UVPLASTIC for more information today.

Need A Trustworthy Supplier Of IRT Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of IRT Polycarbonate Shee and Machining services.