Infrared-Transmitting Polycarbonate: What You Need to Know

Get to know the basics of infrared transmitting polycarbonate, its key properties, and practical applications in technology and industry.

With the advancement of technologies, people now have the power to control devices through invisible infrared rays. This specialized ray or radiation is widely used in various sophisticated and high-tech equipment for military, healthcare, construction, etc. industries.

However, given the higher importance of infrared-transmitting radiation, the mentioned industries are using IR integrated with polycarbonate in handy tools, equipment, and system components. So, what is infrared-transmitting polycarbonate? It becomes a burning question.

The simple answer is that the sheet or component of infrared-transmitting polycarbonate blocks visible and UV lights while allowing the IR to pass. We know as an industry expert, product manufacturer, or professional in a certain sector, this answer is inadequate. So, dive with us to learn the ins and outs of this specialized construction material.

Defining Infrared-Transmitting Polycarbonate

Well, you already know the general definition of infrared-transmitting polycarbonate. Unlike the general polycarbonate, which is transparent to all types of light, IR-transmitting polycarbonate allows the passage of only IR rays. Here, the difference between conventional polycarbonate and infrared-transmitting polycarbonate is the addition of special pigments or coating.

How is IR Transmitting Polycarbonate Produced?

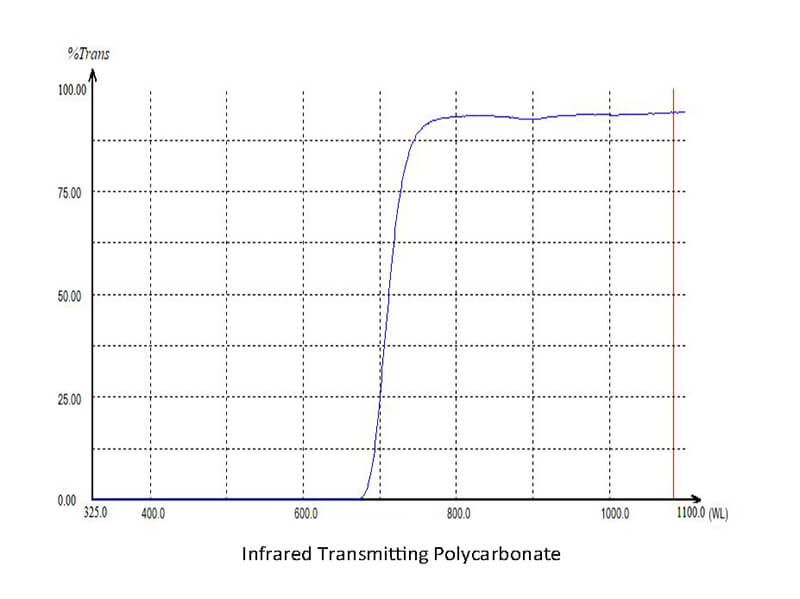

First, some manufacturers add pigments with wavelengths of 700 to 2500 nanometers while synthesizing bisphenol A and carbonyl dichloride within the methyl chloride solvent. Then, centrifugal and filtration processes take place.

After that, the concentrating, cooling, drying, and finishing processes are conducted to get usable polycarbonate. Here, the earlier used specialized pigments demand it, calling it infrared transmitting polycarbonate, not conventional polycarbonate.

On the other hand, some manufacturers use the mentioned pigments with wavelengths of 700 to 2500 nanometers and a coating of special material with wavelengths of 700 to 2500 nanometers to increase the capability of the respective infrared-transmitting polycarbonate.

Selection of Coating for IR Transmitting Polycarbonate

Again, most manufacturers only use coatings that allow the passage of IR while blocking visible and UV lights. The coatings are listed below:

Characteristics of IR Transmitting Polycarbonate

The following points elaborate on the infrared-transmitting polycarbonate’s optical, physical, thermal, and electrical properties.

Optical Properties

Physical Properties

Thermal Properties

Electrical Properties

Other Properties

Common Applications of IR Transmitting Polycarbonate

The points listed below will help you understand the wide variety of applications of infrared-transmitting polycarbonate:

Benefits of Using IR Transmitting Polycarbonate

Knowing the benefits of using infrared-transmitting polycarbonate helps professionals, product designers, manufacturers, etc., is crucial as it helps in the material selection process. However, the following are the benefits of using IR-transmitting polycarbonate in various terms:

Final Words

You now have a clear and comprehensive understanding of infrared-transmitting polycarbonate. As per the basics, it is the same as conventional polycarbonate plastic, with an exceptional characteristic. Here, the exceptionality is that it allows infrared rays to pass and block visible and UV rays.

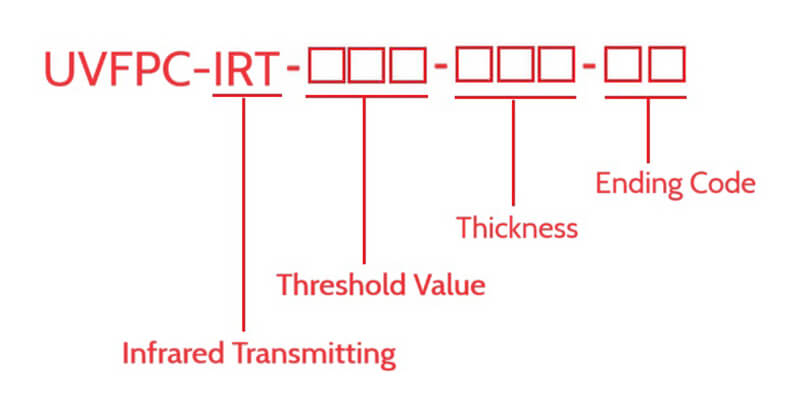

Finally, the price of an IR-transmitting infrared polycarbonate sheet varies depending on size, thickness, coating type, usability, seller, manufacturing country, etc. To get the actual price, you must contact the suppliers directly.

UVPLASTIC is a leading supplier of IR transmitting polycarbonate in China. In the meantime, it provides machining services. Contact UVPLASTIC for more information today.

Need A Trustworthy Supplier Of IRT Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of IRT Polycarbonate Shee and Machining services.