All About Infrared-Transmitting Plastic: Uses and Properties

Infrared-transmitting plastic allows infrared light to pass while blocking visible light. Discover its uses, properties, and applications in various industries. Learn more!

Infrared (IR) light is what we can’t see at all but detect as heat. Have you ever imagined an efficient material that can pass through this invisible light spectrum? This is infrared-transmitting plastic.

This is in the range of high-grade plastics that allow infrared (IR) light to pass through them with minimal absorption or distortion. Now, what more can you expect here?

As well as transmitting IR light, it effectively blocks UV rays and other normal light. This special property makes it an outstanding material for various technological and industrial applications. Plus, its robust durability and high resistance to various unwanted environmental factors make it a reliable choice for demanding conditions.

Read on to learn many more unknown facts about this specialized plastic.

A Quick Overview of Infrared-Transmitting Plastic

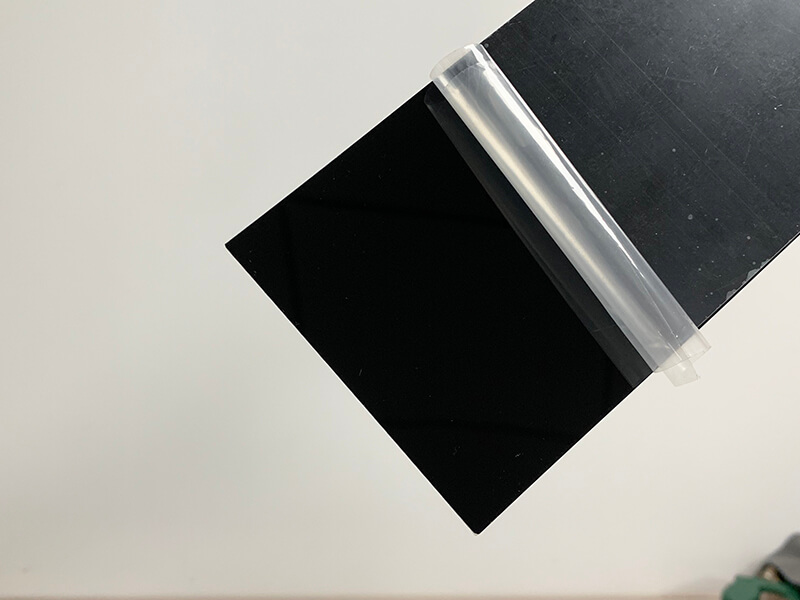

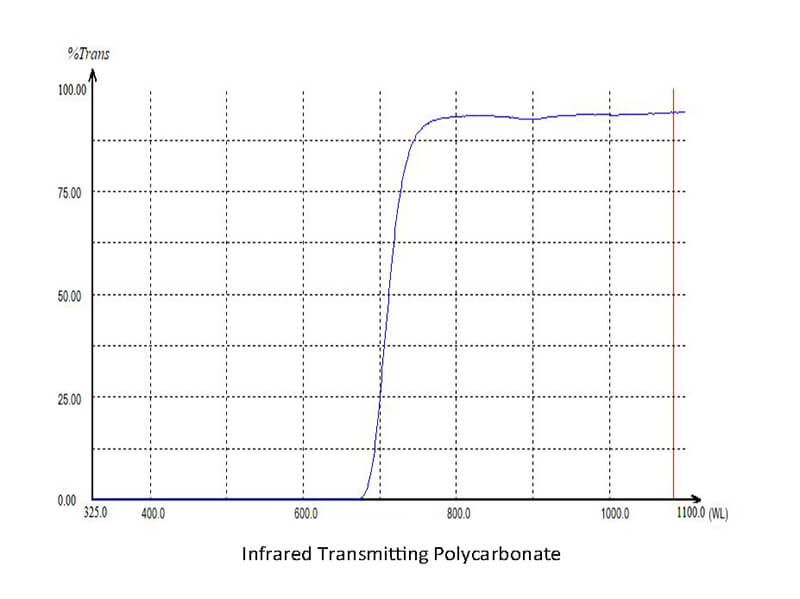

Infrared-transmitting plastic is the most common type of opaque or semi-opaque black plastic that allows a fluent IR transmission while blocking harmful UV rays and other visible light. It can transmit IR light, typically in the wavelength range of 700 nm to 1100 nm.

There are various types of plastics in this range that are made from polymers like polycarbonate, ABS, or specialized PMMA treated to enhance IR transmission.

People most often know it as infrared-transmitting acrylic and infrared-transmitting polycarbonate. These are the most common types of infrared plastic favored for high-end and precision optical uses.

How Infrared Transmitting Plastic Works?

The core working formula of infrared plastic blocks UV rays and other environmental factors while allowing IR rays to reach the destination. This is mainly done by the unique molecular structure of specific formulated material properties, which creates a blockage for species wavelength.

In most cases, it can be made opaque or semi-opaque, which blocks or reduces the visible light region.

Also, the plastic’s additives determine which wavelengths of light can pass through and allow a high transmittance percentage in the infrared region, starting at 700 nm and beyond.

For example, when you press a button on the remote, it generates an infrared signal. This signal passes through the infrared-transmitting plastic window and is directed toward the device you want to control. By blocking unwanted visible light, the IRT ensures a clear path for the IR signal in this instance.

Different Types of Infrared Transmitting Plastics Used in Industries

There are different types of infrared-transmitting plastic available used for different purposes in applications. Here are some common types with their particular characteristics you should come to know:

Infrared Acrylic

These common types of transmitting sheets are made from acrylic, a highly durable plastic known for its optical clarity and robust resistance to wear and tear. Acrylic sheeting has almost the same physical protein as traditional acrylic sheeting, but the only difference is in the IR transmission capabilities.

Infrared Polycarbonate

As with other infrared plastics, infrared polycarbonate is designed to transmit two types of infrared light, IRA and IRB, while blocking UV rays. Compared to others, the infrared-transmitting polycarbonate has excellent light transmittance and optical properties that ensure high transmittance (88%) and transmit long-wavelength infrared rays.

These special characteristics make infrared-transmitting polycarbonate useful in many environments for potential uses.

iR transmitting pMMA sheet

PMMA is one type of infrared plastic that typically filters UV rays of light with wavelengths shorter than about 300 nanometers (nm). Some manufacturers add special coatings or additives to PMMA that enhance UV absorption and infrared (IR) light transmission with wavelengths up to 2,800 nm.

While it allows some IR light to pass through, it isn’t optimized for transmitting longer IR wavelengths beyond 2,800 nm.

Infrared Optical Plastics

Infrared optical plastics are particular types of plastics that let infrared (IR) light pass through easily without blocking or distorting it. Other traditional plastics are made from hydrocarbons, this new type of optical plastic is made from sulfur. The use of sulfur in its chemical structure makes it robust to pass through the IR light from the device.

Critical Properties of Infrared Transmitting Plastic

As the name suggests, infrared-transmitting plastic is mainly characterized by its unique ability to transmit IR light. Beyond that, some key properties make it suitable for different applications.

| Property | Description |

|---|---|

| IR transparency | It has a good ability to pass through the iR (>88%) at wavelengths between 850 and 1100 nm. |

| Low visible light transmission | It effectively blocks less than 1% of visible light at wavelengths between 400 and 700 nanometers. |

| Optical clarity | It maintains good clarity to transmit IR without distortion. This makes it perfect for imaging and detection in optical systems. |

| Durability | According to ASTM D638, the elongation at the break of the plastic is measured up to 100%. It clearly highlights its high durability against various environmental factors like temperature changes, UV exposure, and chemicals. |

| The hot deformation temperature | The hot deformation temperature of most infrared plastic is 132 °C. It is quite sufficient for applications that do not involve high temperatures, such as remote controls, sensors, or indoor devices, |

Applications of Infrared Plastic in Our Everyday Technology

Infrared plastic is now an essential part of model technology that effectively utilizes infrared (IR) light for various purposes. Here are some common factors where you will find this specialized plastic:

Infrared Cameras and Sensors

Infrared cameras and sensors use infrared plastic in lenses and windows to transmit IR efficiently. These devices also have high IR transmissions without visible light interference, which is a big plus, as they allow the detection and capture of IR images easily.

Protective Covers

Protective covers are made from infrared plastic that works as a shield for sensitive electronic components and saves them from dust, moisture, and physical damage. Besides this, the plastic ensures an effective IR signal so devices like remote controls and communication equipment work properly.

Infrared Filters

Infrared filters often use infrared plastic to improve picture quality. Plastic mainly blocks unwanted light and helps capture clearer and more detailed images.

Thermal Imaging

Thermal imaging devices use infrared plastic to show heat. This plastic effectively handles high temperatures, making it perfect for firefighting, industrial checks, and medical tests, which require accurate temperature readings.

Communication System

Various communication devices, such as fiber optics, remote controls, and plastic, use plastic to send data through infrared signals. Plastic is strong and clear enough for infrared light transmission and makes communication efficient.

Medical Devices

Medical devices use infrared plastic for safety and efficiency. The plastic mostly finds diagnostic tools, therapy equipment, and monitors to ensure precision medical care.

Factors You Should Consider When Selecting Infrared Plastic

Now that you are in the market and confused about the right plastic for your industry, here are a few major factors that you should consider:

Wavelength Range

Before checking anything else, make sure the plastic you choose is perfect for the specific infrared wavelength range needed for your application. It would range from mid-infrared to near-infrared.

Thickness and Form Factor

The thickness of the plastic has a high impact on its transmission properties. So check and determine the required thickness and form for your application.

Durability

Durable plastics will last long and perform well even in harsh environments. So, look at how well the plastic can handle bumps, scratches, and tough conditions.

Fabrication and Processing

Above all, ensure that the plastic is suitable for your desired manufacturing process. See how easily the plastic can be cut or shaped to facilitate your project.

Reliable Supplier

In case you are confused at any point, it is always best to contact a trustworthy supplier for further discussion. They will help you get reliable materials and help when needed.

In Closing

Here is all for you about the infrared transmitting plastic. Beyond any doubt, infrared-transmitting plastic is a demanding element in certain industrial needs where IR transmission with other wavelength interruptions is necessary. All you need to ensure is the right usage of plastic for your business purpose.