What is Thermoforming Polycarbonate Sheet?

Thermoforming is typically a procedure that involves heating a plastic sheet to a specific temperature to create a mold or shape. When it comes to thermoforming polycarbonate sheets, is a procedure that entails changing the structure and shape of a polycarbonate sheet using various methods.

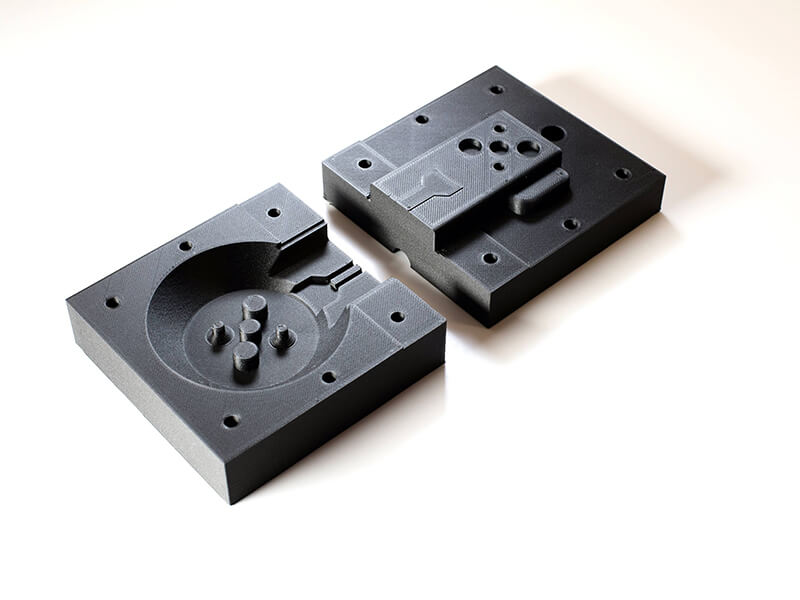

The most popular method includes pressing a heated thermoplastic sheet into a mold to achieve the desired shape. As a result, the thermoplastic can cool and maintain the mold’s basic requirements as well.

Furthermore, thermoforming a polycarbonate sheet presupposes heating it to a certain temperature, usually below the melting point. The materials can soften as they are heated until they stretch to fit the outlines of the mold.

When this plastic comes into contact with the mold, it can take on the mold. And now trim this mold so that it can be used. When handling large objects with complex requirements, a process like this would be cost-effective.

You must incorporate necessary user-friendly modifications to the thermoplastic sheet to achieve better performance. Since the procedure is repeatable, such a design would ensure uniformity.

Pros and Cons

As the thermoforming polycarbonate sheet is more technologically focused, it has a range of advantages. Many people who enjoy this method credit it to the rapid turnaround times and low cost. You’ll notice that these two significant advantages are what make it ideal for low-volume manufacturing.

The following are some advantages of thermoforming:

As you might be aware, thermoforming is not without its disadvantages.

The following are a few of them:

Nonetheless, the benefits of thermoforming polycarbonate overcome its drawbacks.

How is it made?

Before you make thermoforming polycarbonate, it is essential to have a logical concept of the thermoforming processes. The right skills and equipment are one of the benefits of this operation.

Let’s take a look at some of the most popular approaches to designing plastic components.

Pre Drying

The first step in the thermoforming process is to pre-dry the material. At 125 degrees Celsius, the method works well. It can consume a lot of moisture at such a high temperature.

As a result of the trapped moisture, bubbles will form in the layer. The products can be dehumidified in the oven. It’s important to keep the sheets one inch away. You should also keep the temperature under control until the process is completed.

The length of time this pre-drying process takes is determined by the thickness of the paper and the amount of moisture it absorbs. After you’ve completed the pre-drying process, immediately move the material to a forming machine.

Heating

The quality of your heating is crucial to your overall performance. Usually, on polycarbonate, temperatures of 180 to 190 degrees are used. It can transform into a variety of shapes and structures even at a high temperature.

To ensure even heat distribution, you can use a temperature control mechanism. As an alternative, infrared heaters can be used. The heaters are likely to heat the materials’ surfaces at a rapid pace. You should exercise caution to avoid overheating, as this could cause degradation.

Shaping the material

It is necessary to remove the heating elements before beginning the healing process. The materials will be placed to define the mold and allow it to take the desired shapes. It will shrink as it loses heat, emulating the behavior of the molding materials. You will most likely achieve the desired shape if you do so.

Cooling

The final step is to cool the product. While you wait for the final product, you can complete this step as smoothly as possible. Placing your mold in the cooling jigs is also beneficial. Warping should be avoided in this arrangement. It would also be simpler to achieve room temperature.

Applications of Thermoforming Polycarbonate

Thermoforming is used in a variety of industries to create a variety of products. The following are the most widely used applications:

Automotive Manufacturing Industry

Thermoforming is widely used in different parts of vehicles.

As arguably the most robust material, Polycarbonate is used to make various vehicles, especially during assembly. Parts like dashboards, interior door panels, air ducts, bumpers, and engine bay panels are made of thermoforming polycarbonate.

Aviation and Aerospace

Polycarbonate thermoformed materials are most commonly used in the aerospace and aviation industries. Window shades are an excellent example of a thermoformed polycarbonate component on an airplane. This material is also used in the following elements:

Medical Industries

Another field that benefits from thermoformed materials is medicine. Equipment like X-ray machines, CT and MRI scans, Sterile packaging, Trays and bins, Hospital bed equipment, and Other medical electronics are made from it.

Office and Business machines

Official Tools like computer enclosures, fax machine enclosures, office furniture, and bezels use thermoforming materials.

Building and Construction

Thermoforming carbonate is used to make a variety of buildings and construction materials. The following are the most popular applications in this industry:

Things to consider while buying

Thermoforming devices come in a variety of shapes and sizes. You should consider the following considerations to choose the best one.

Adaptability

The ideal thermoforming system should be simple to operate. It would be suitable if you participated in any exercise. You will be able to use the system with no problems if you do so.

Safety Features

To avoid many accidents, a good computer should have adequate safety features. Are you aware that the whole thermoforming process carries several risks? To ensure protection, the computer should be equipped with the necessary equipment.

Units of Control

Since technology is constantly strengthening, it would be more fitting to purchase the most recent versions with more natural control units. The controls are necessary features for determining different thermoforming processes. Your devices should be equipped with the required commands to ensure that operations run smoothly.

Size

Size should be one of the most important factors to consider when choosing the right machines. Different sizes will cater to the user’s various requirements. Since they are mass-produced, some people will opt for larger sizes.

Warranty

You should be aware of the warranty policies. Some machines come with a warranty on specific items. It’s also important to know if any items come with a lifetime warranty.

DIY

Your employees can learn the basics of the thermoforming method and how to solve problems and troubleshoot problems rapidly.

Here you can get started with:

Final Words

Here you are! This is only a concise summary of thermoforming and its many benefits over other plastic component and product manufacturing techniques.

Thermoforming is an old concept that involves molding a variety of plastic materials into specific shapes. To carry out this procedure, however, you must have the necessary knowledge. You should also use the appropriate plastic materials.

UVPLASTIC is a leading supplier of thermoforming plastic in China, if you are planning to make some plastic parts, contact us now!