Rapid Prototyping Services & Low-Volume Manufacturing

Trustworthy Supplier of Rapid Prototype for Automotive Light In China

Rapid plastic prototyping is a fast production for physical parts, models, and assembly parts with a small amount, the main materials are engineering plastic (PMMA, ABS, Polycarbonate, etc.), metals (aluminum, cup rum, steel), and Silicone. It is a popular method in Automotive, Medical devices, Product Development, and industrial design fields. Normally, low-volume manufacturing will be needed after rapid prototyping.

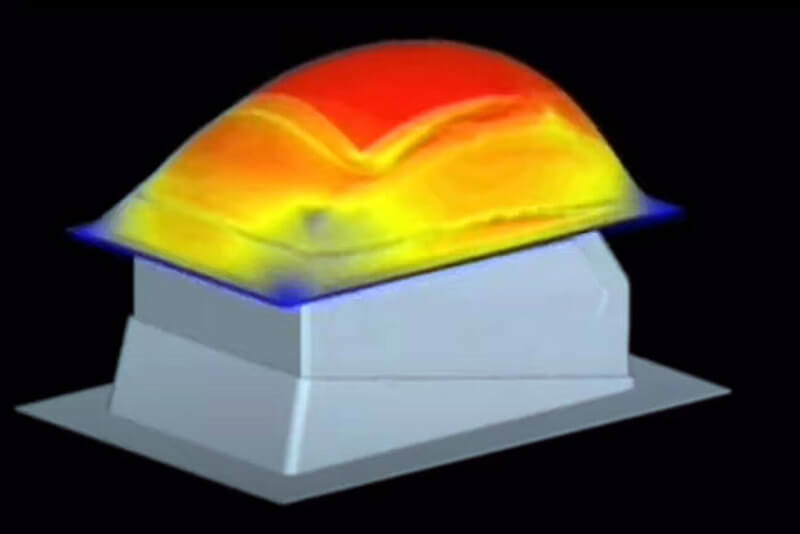

Rapid prototyping is the best way to verify the design of your new plastic product, which is designed by 3D computer-aided design (CAD), like UG, CATIA, Solidworks, Auto CAD, etc. It is an example of your new product that you plan to manufacture in large quantities. You will spend a short time and meager investment to make rapid prototyping, which can match very closely with the final product, therefore, you can know the difference between your design and the real product before manufacturing in large quantity.

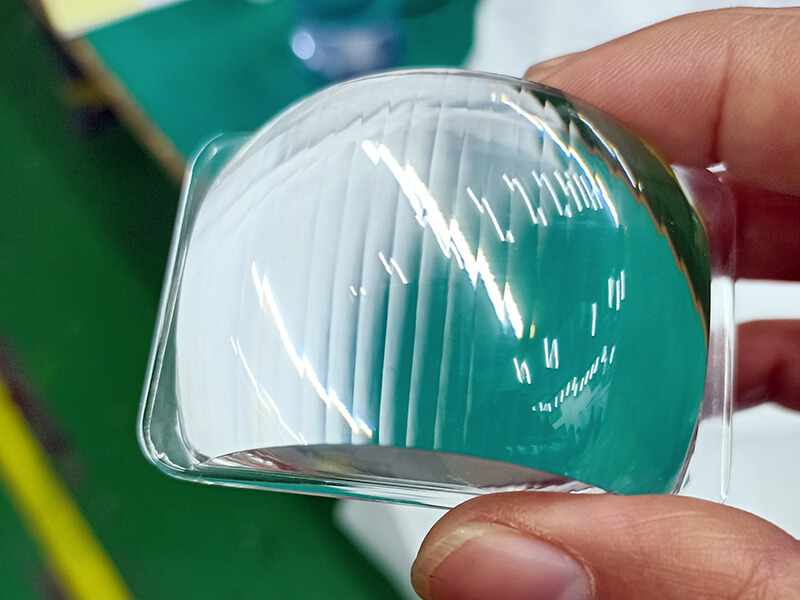

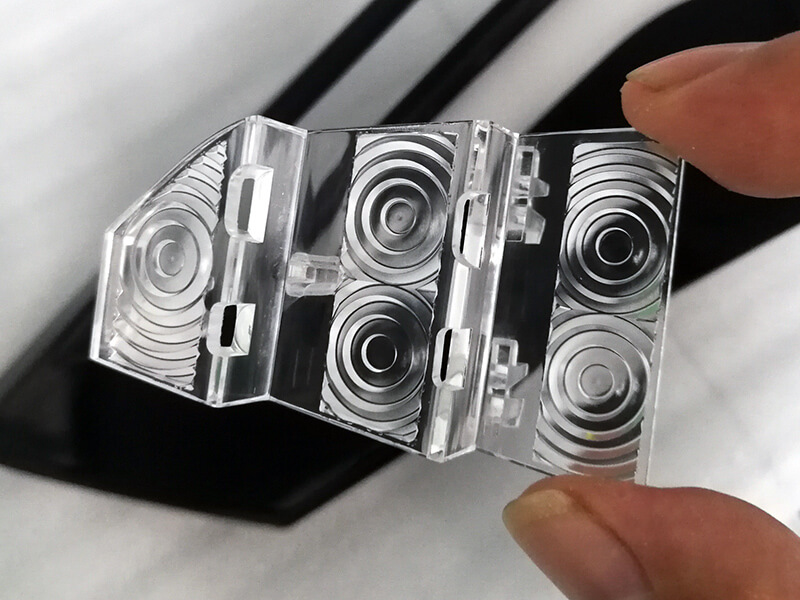

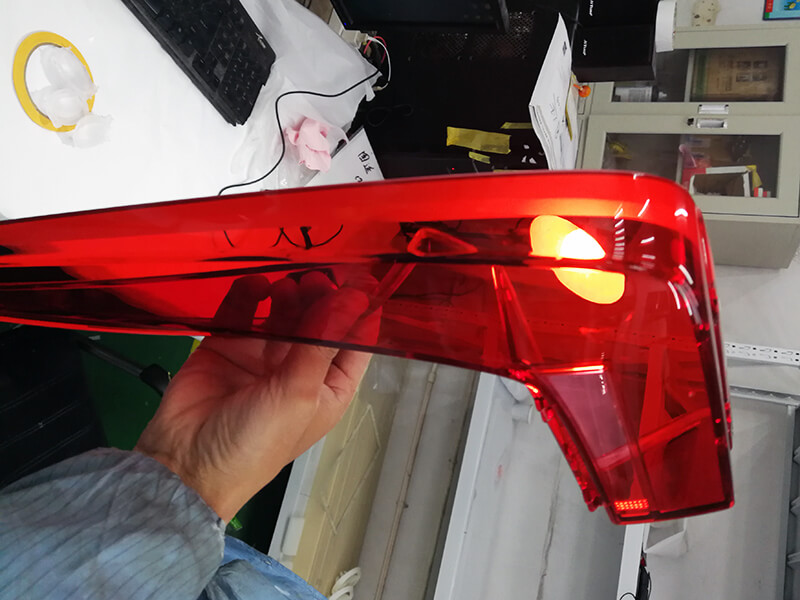

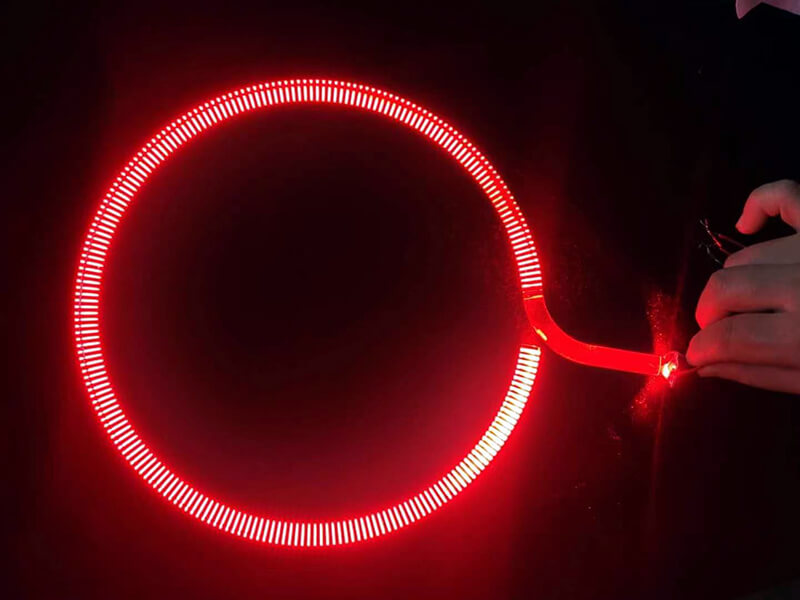

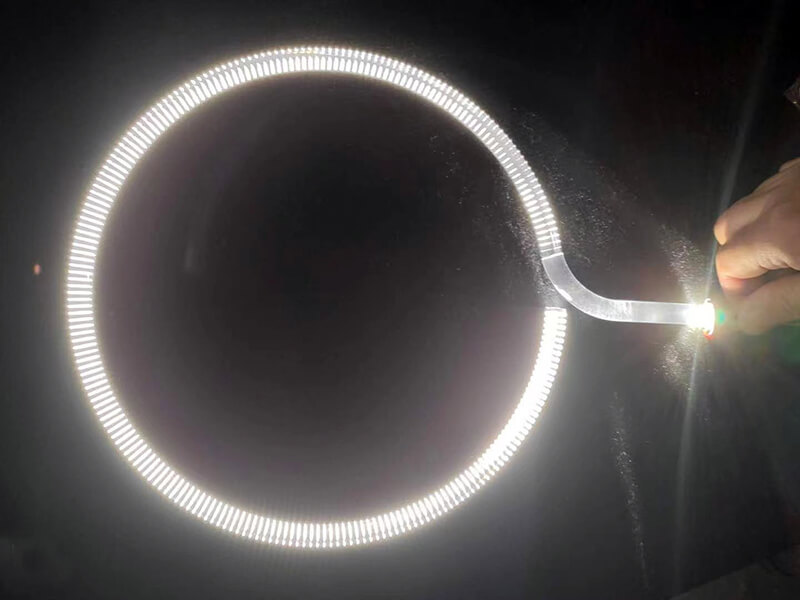

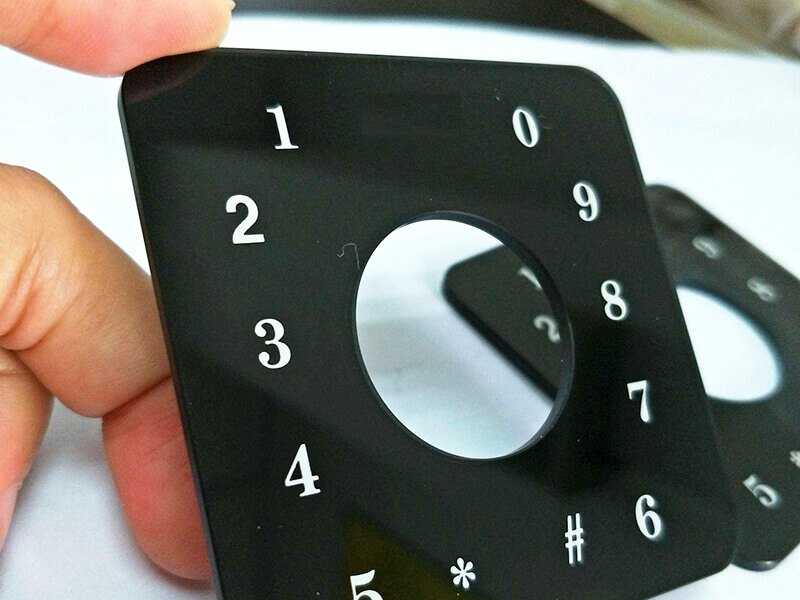

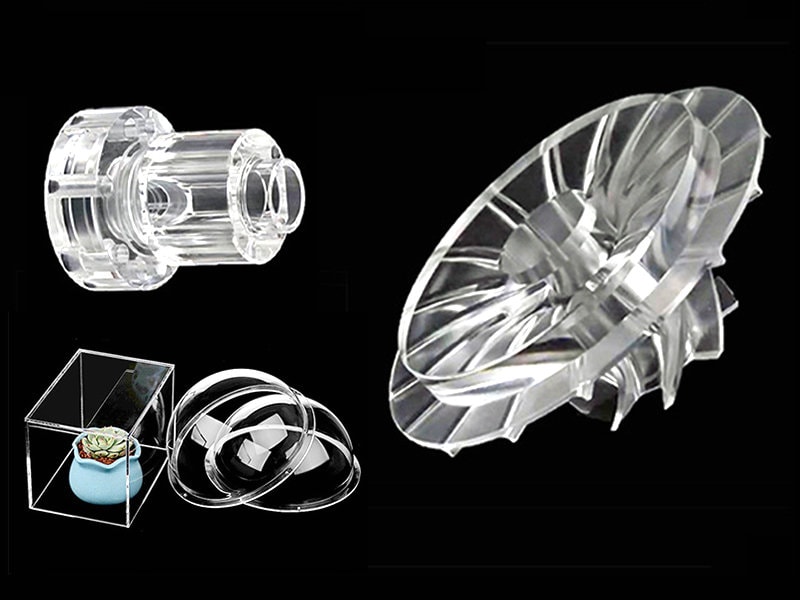

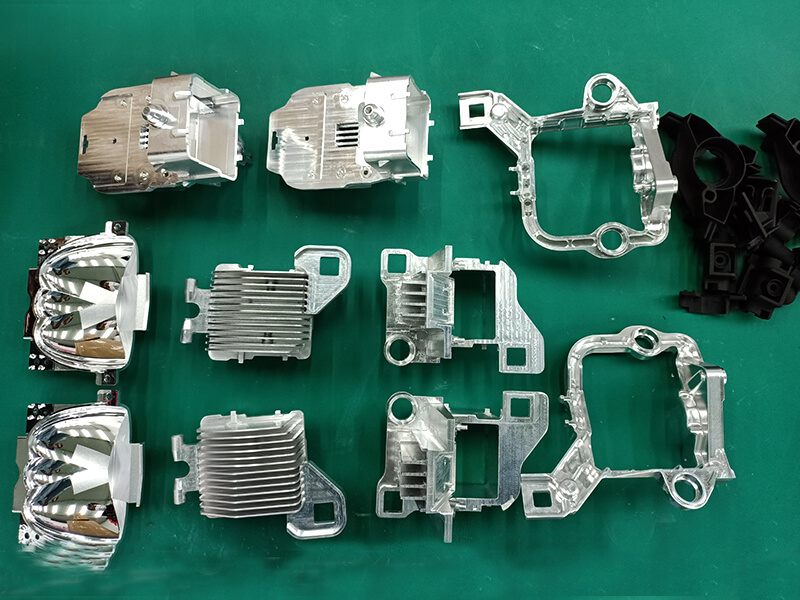

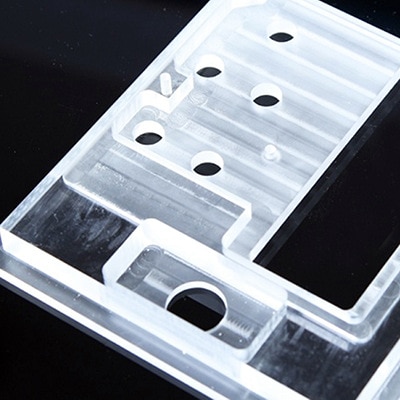

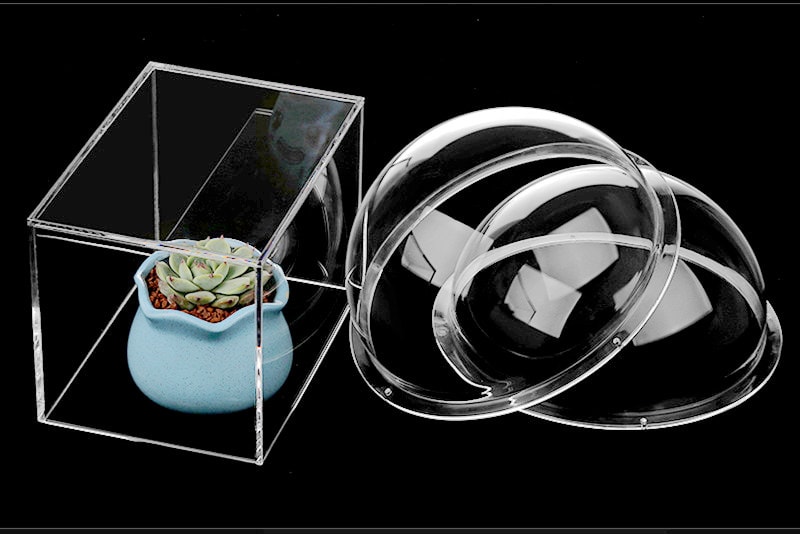

Rapid prototyping for automotive lighting is manufactured by engineering plastic, such as polycarbonate (PC), Plexiglass (PMMA), ABS, Polyethylene (PE), polyformaldehyde (POM), PEEK, etc. Most automotive lighting prototypes are clear optical parts made of transparent acrylic (PMMA) and polycarbonate (PC) for example, automotive lighting lamp lenses, light guides, or product external components, displays, etc.

Low-volume manufacturing is a specialized service, that offers the same quality parts as a full production, but quantity can be a single piece to hundreds of pieces. It’s an efficient process to move an idea from the concept stage through prototyping, and from there as a bridge to full-volume production.

UVPLASTIC has more than 15 years of experience in rapid prototyping for automotive lighting. Today, we have grown to be a leading supplier in China, our clients are automotive lighting manufacturers, R&D companies, and automakers, like Audi, Volkswagen, Volvo, Chevrolet, Citroen, Infiniti, Peugeot, Buick, etc.

Rapid Plastic Prototyping and Low-Volume Manufacturing Service

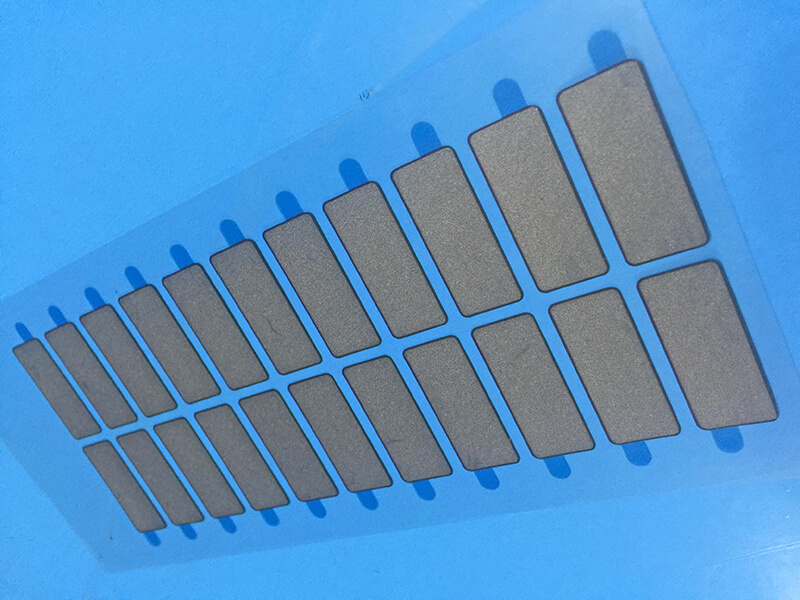

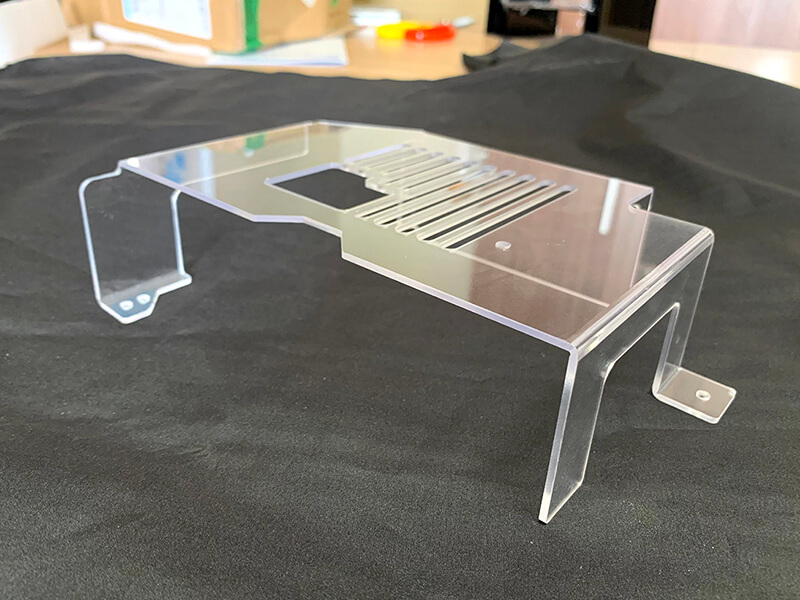

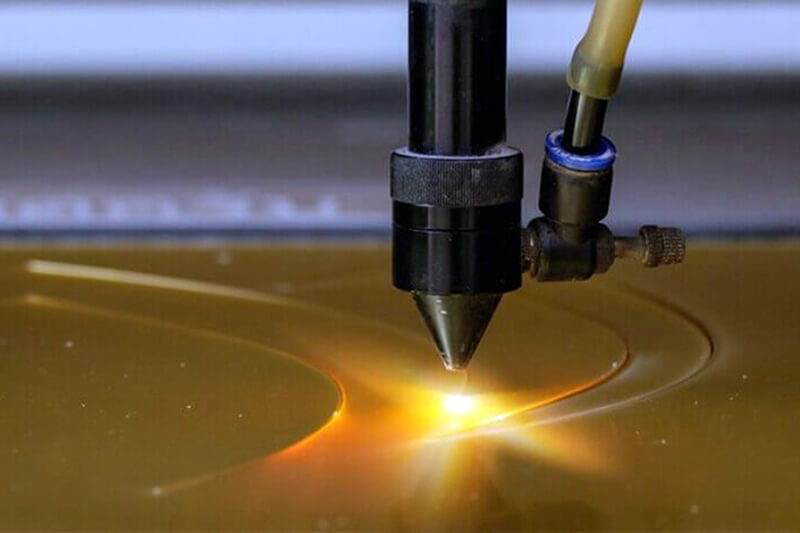

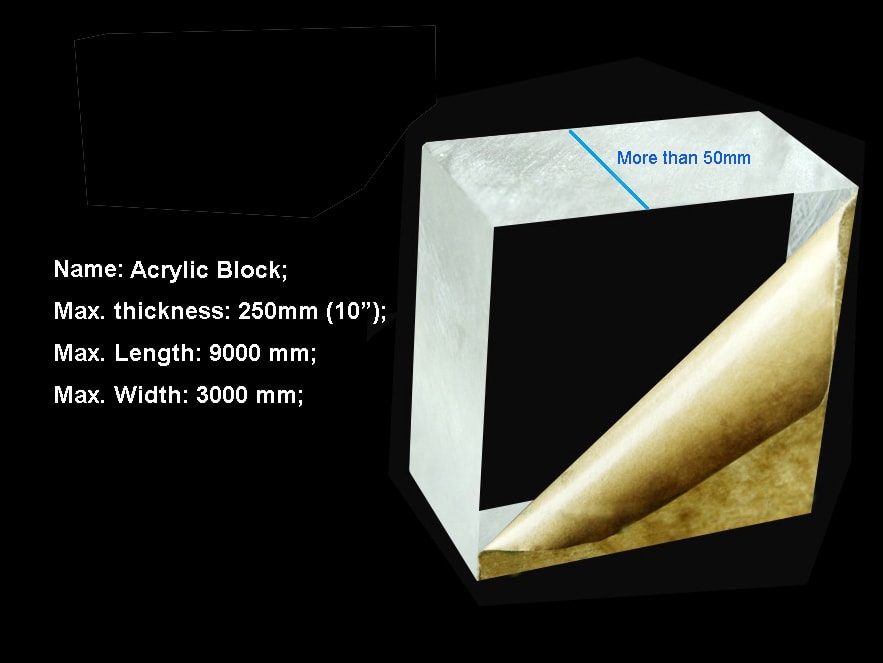

CNC Rapid Plastic Prototyping Service

CNC Rapid Plastic Prototyping is a precision machining process to create high-fidelity prototype parts for in-development automotive lighting parts in small amounts, the popular processing technologies are CNC milling/carving, CNC turning, etc. CNC-machined prototypes are made from the same material as your product and will be manufactured in large quantities by using production technologies like injection molding. Normally, we use solid materials, such as polycarbonate sheets, plexiglass sheets, acrylic blocks, plexiglass rods, and some metals, like aluminum. With the polishing surface, you can get great automotive lighting prototypes with excellent optical properties.

It is the best solution for custom plastic prototypes, such as automotive lights, and can meet your strict requirements including the same material as your new products, tight tolerances, complex geometries, and fast delivery.

UVPLASTIC began to manufacture rapid prototyping services for global manufacturers of automotive lights in 2006. With excellent CNC prototyping capabilities, we are providing highly accurate plastic parts and functional prototyping for more than 1200 clients from 40 countries.

Frequently

Asked

Questions

Learn more about CNC Machining Rapid Prototyping Technology or just want to say hello to us.

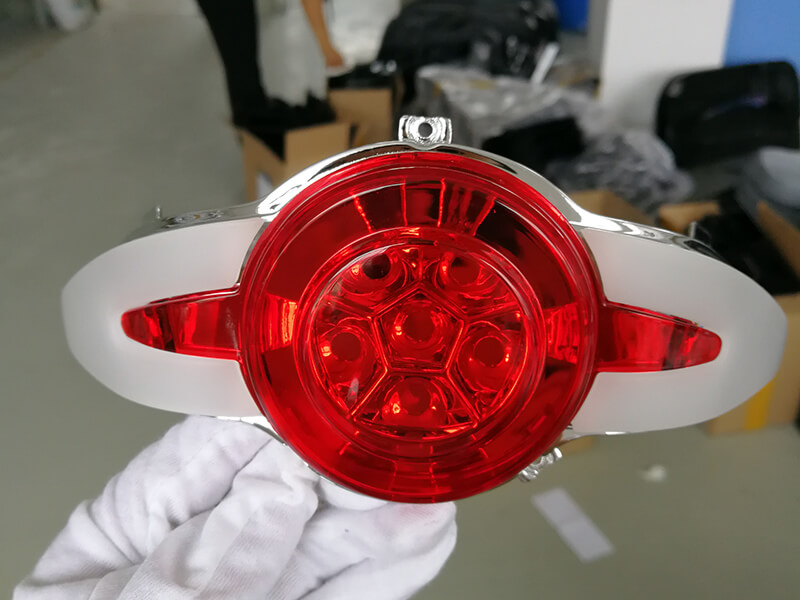

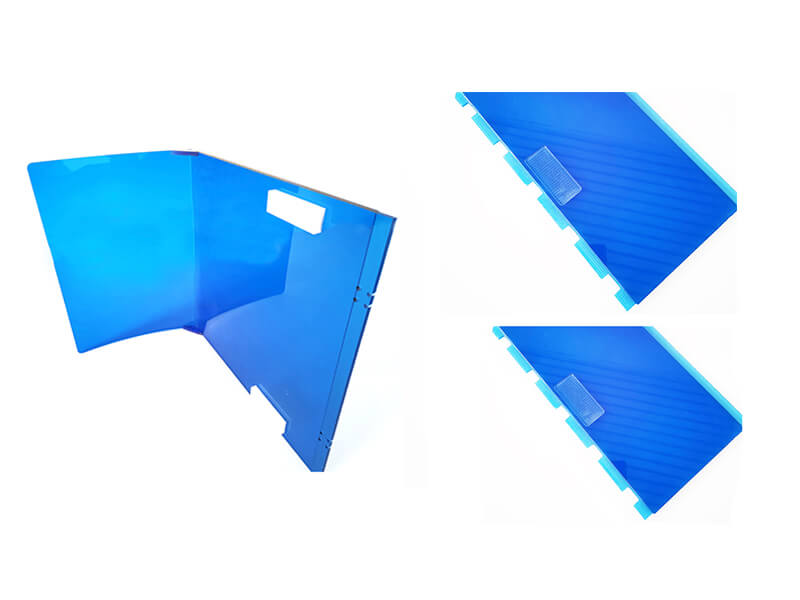

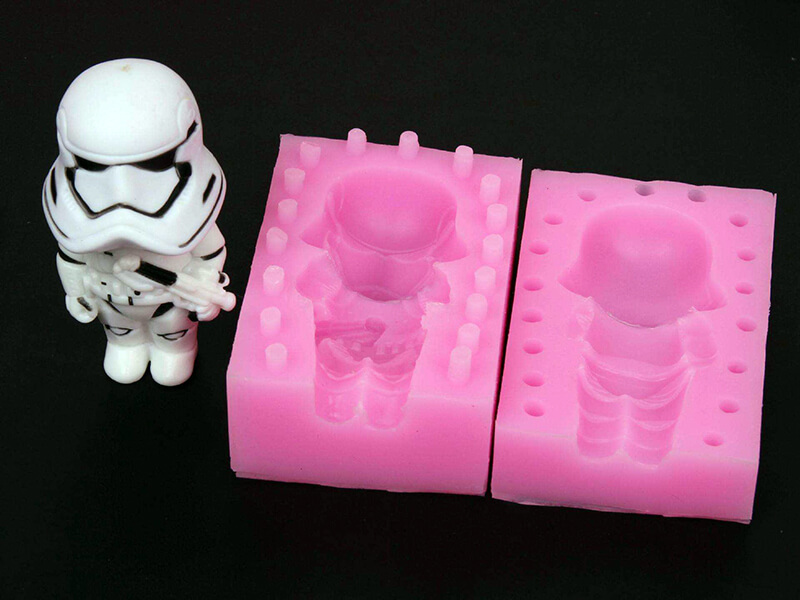

Vacuum Casting for Rapid Plastic Prototype

Vacuum casting is an economical prototype manufacturing process for plastic rapid prototypes and new functional prototypes fastly, also known as “urethane casting”. The main materials of vacuum casting mold are silicone and polyurethane. Most prototype suppliers like this process, because vacuum casting prototypes are cost-effective, fast delivery, wide-ranging in materials/colors, and have excellent surface quality. Vacuum casting rapid prototype is the best choice for automotive lighting prototypes, pre-launch product testing, small series of housings and covers, and concept models.

Technical Specifications for Vacuum Casting Rapid Prototype

| No. | Item | Description |

|---|---|---|

| 1 | Max. Part Size | 2000x1200x1000 mm |

| 2 | Min. Wall Thickness | 1mm; Suggested Wall Thickness is from 1.5 to 2.5 mm |

| 3 | Tolerance | ±0.1mm/100mm |

| 4 | Prototype Quantity By Silicone Mold | From 20 to 40 Copies for Each Silicone Mold |

| 5 | Leading Time | One week according to 50 copies |

| 6 | Surface Options | Colored, Textured, Frosted, Electroplate Painted, Polished |

How Does A Vacuum Casting/Urethane Casting Work?

Interested in vacuum casting rapid prototypes for automotive lighting and want a fast quotation.

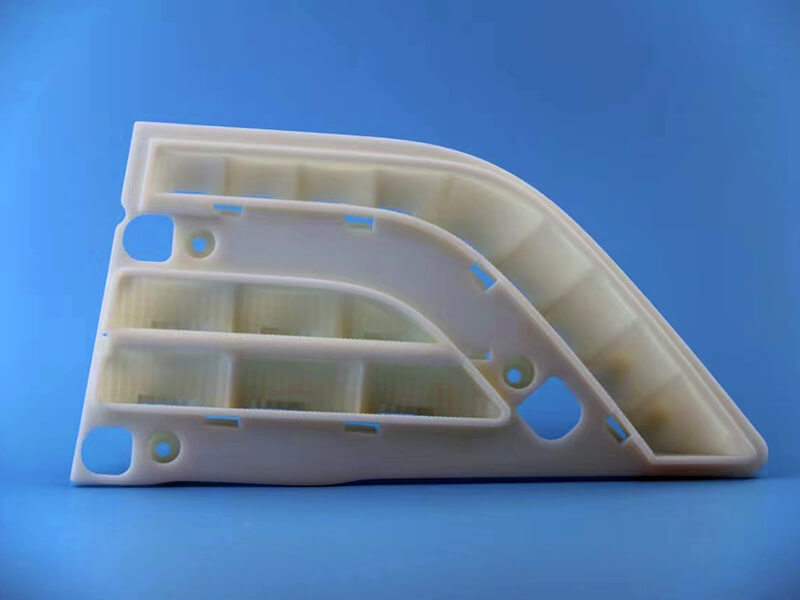

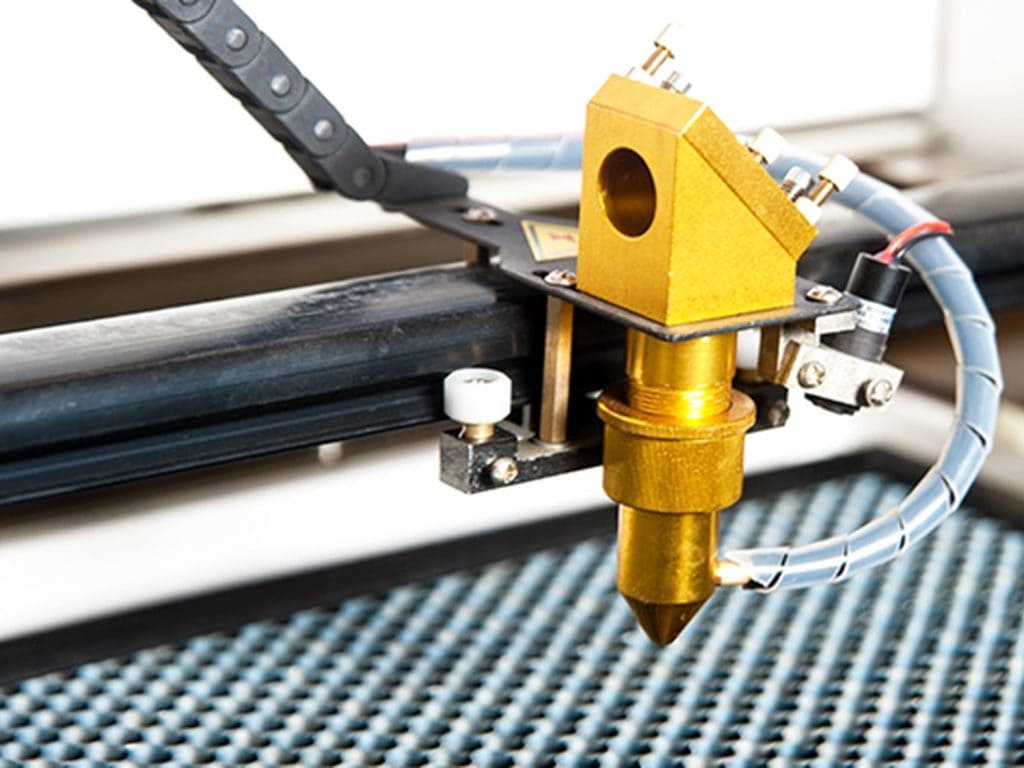

3D printed rapid Plastic prototypes for automotive lighting

3D printing is an additive manufacturing technology, that was devised in the 1980s, also known as rapid prototyping. This technology works by adding layer upon layer of material to build up a complete object. 3D printing technology can create a physical object from a digital model file, it enabled companies to develop prototypes quickly and more accurately than with other methods. Therefore, it plays an important role in automotive lighting prototypes.

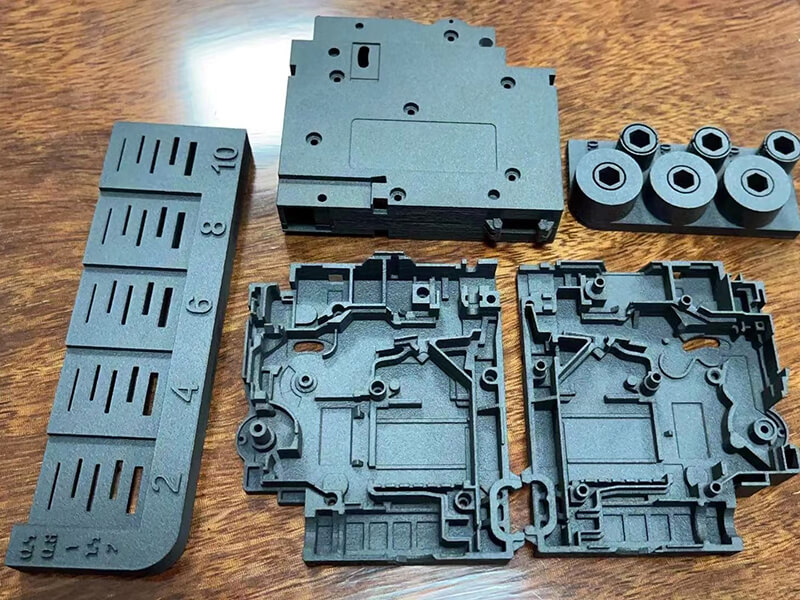

3D printing includes a series of rapid prototyping technologies, but we are using two of them for automotive lighting prototypes, including Stereolithography (SLA) 3D Printing and Selective Laser Sintering (SLS) 3D printing.

With more than 15 years of rapid prototyping for automotive lighting in China, UVPLASTIC has 12 professional engineers for 3D printing services, who can support you with your rapid prototyping. As a leading supplier of 3D printing services and rapid auto lighting prototypes in China, we know more about material and processing technology.

Technical Specifications for 3D Printing Rapid Prototype

Still have questions about 3D printing rapid automotive lighting prototypes.

| No. | Item | Description |

|---|---|---|

| 1 | Max. Working Area | SLA: 1700 x 800 x 600 mm SLS: 680 x 360 x 560 mm SLM: 160 x 160 x 100 mm |

| 2 | Standard Layer Thickness | SLA: From 0.05 to 0.15 mm SLS: From 0.05 to 0.2 mm SLS: From 0.02 to 0.1 mm |

| 3 | General Tolerances | SLA: 0.05 mm SLS: 0.1 mm SLM: 0.03 mm |

| 4 | Elevator Precision | ±0.01mm |

| 5 | Material Colors | Transparent; Translucent; Opaque: White, Gray, Black, Light Green, Brown, Yellow |

| 6 | Excellent heat resistance | Milky white (260 ℃), Transparent red (130 ℃) |

| 7 | Metal powder | Titanium alloy (TC4); Aluminium alloy (AISi10Mg); Die block steel; |

| 8 | Leading time | 5 working days |

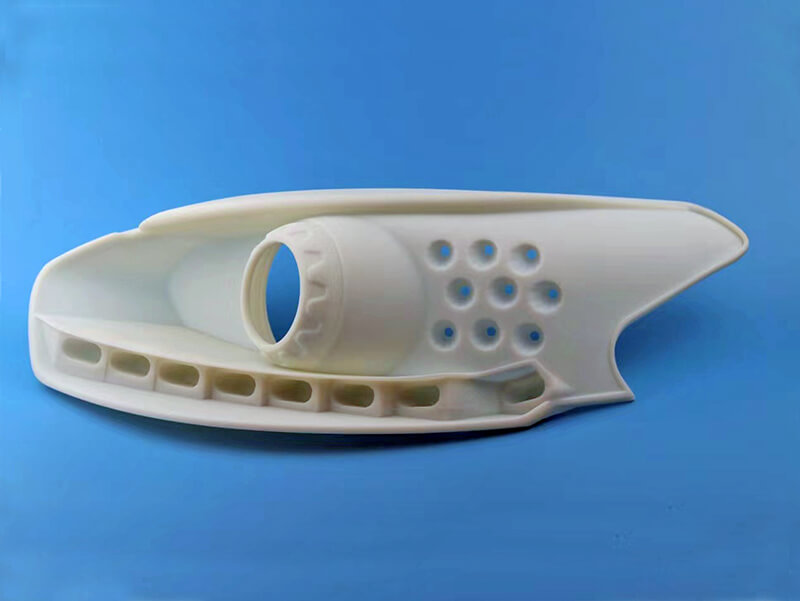

What is Stereolithography (SLA) 3D Printing?

Stereolithography (SLA) printing is an additive manufacturing process that uses ultraviolet (UV) light on liquid photopolymer material, such as ABS, PP, PC, Ceramic, etc. It builds rapid prototypes layer by layer, which is designed by computer-aided design (CAD) software. The supporting structure of prototypes can be built during printing and can be removed manually after parts are completed.

The rapid prototypes are washed by solvent to remove uncured liquid material, then, the prototypes will be solidified in a UV light oven. The colors of prototypes can be transparent, translucent, or opaque, like white, black, gray, green, amber, etc.

With a wider selection of materials, SLA is more and more popular for complex plastic prototypes, the surface of the final part can be embossed, engraved according to clients’ requirements. SLA is a very popular manufacturing process for the auto industry.

What is Selective Laser Sintering (SLS) 3D printing?

If you still have questions about SLA 3D Printing, we are happy to help you.

SLS 3D printing is another additive manufacturing process by using powdered raw material, including engineering plastic (Nylon, PA, PS, PAEK), metal, ceramic, or glass powders, etc. The powdered raw material is placed in a container, a laser selectively sinters and fuses the powdered material then builds a part layer-by-layer according to designed parts by computer-aided design (CAD) software or by scanning real parts.

The main advantage of SLS is that it doesn’t need a support structure. The unsintered powder provides the part with all the necessary support. For this reason, SLS can be used to create freeform geometries that are impossible to manufacture with any other method. Otherwise, SLS offers great bond strength between the layers.

There is no doubt that SLS printing has become an excellent manufacturing process for the auto industry.

Low-Volume Manufacturing

When designers, engineers, and businesses take product development into consideration, they will choose prototyping and mass production. But it isn’t an ideal choice risk sometimes, because they don’t know if it is 100% Successful design. Therefore, low-volume manufacturing is the optimal choice in this case. Low-volume manufacturing is considered to be a specialized service, which creates the same quality parts, the quantity ranges from several pieces to thousands of pieces.

Advantages of Low-Volume Manufacturing

History Project About Rapid Prototype

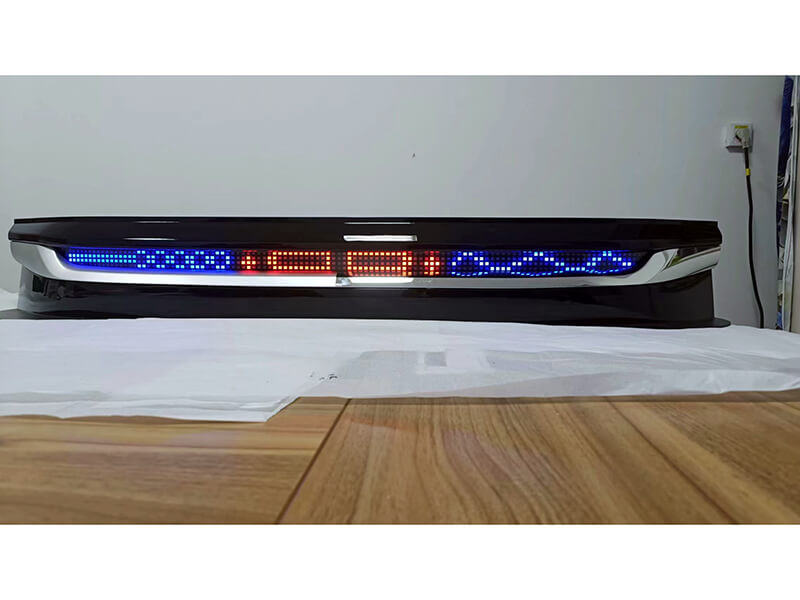

Head Light Prototypes

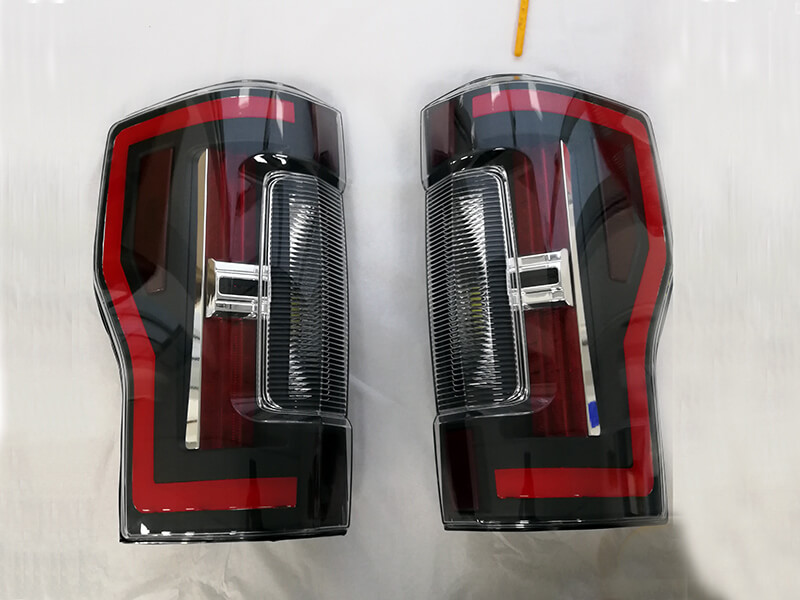

Tail Light Prototypes

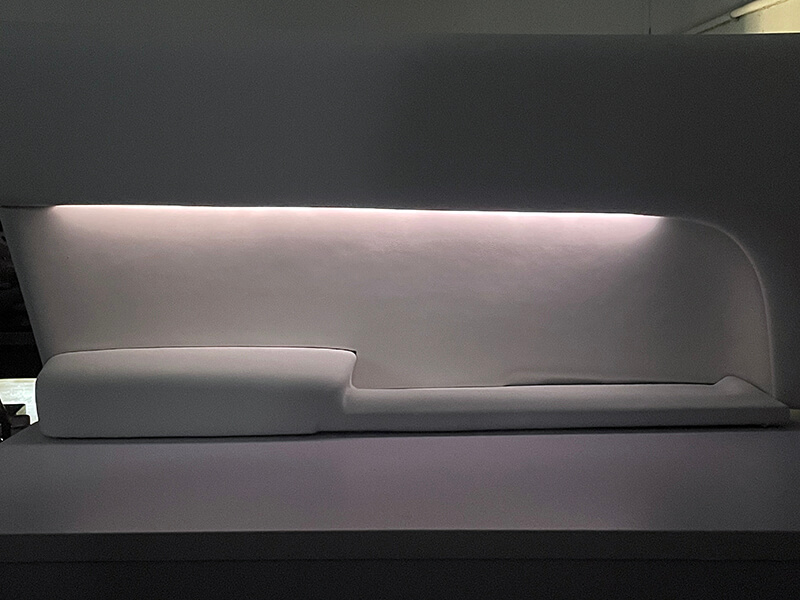

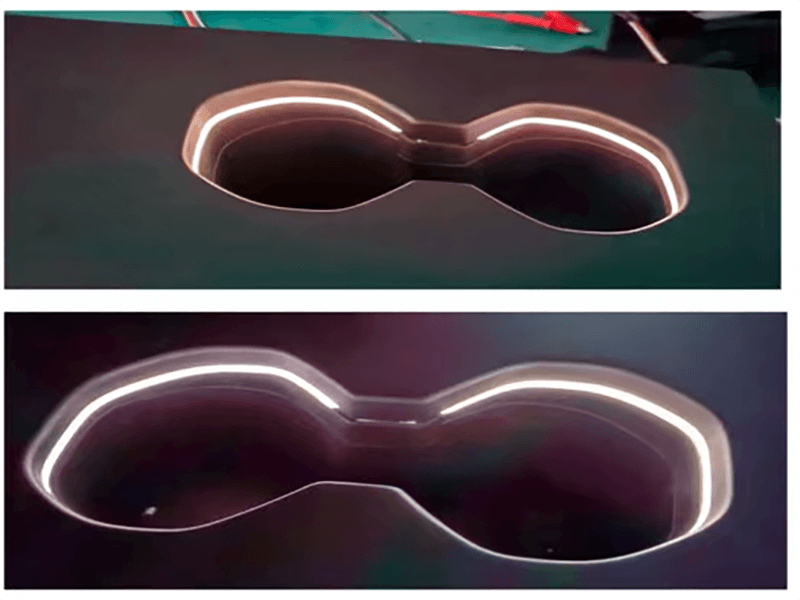

Ambient Lighting Prototypes

Grilles LOGO Prototype

Related Machining Process

Related Articles

Need A Trustworthy Supplier Of Polycarbonate

Click on the button, you will find the Trustworthy Supplier Of Polycarbonate Sheet/Rod/Tube/Film or Machining services.