Best Custom Plexiglass and Acrylic Supplier In China

As the custom plexiglass and acrylic supplier in China, with more than 15 years, UVPLASTIC has grown to be a leading supplier in this field and knows better about acrylic sheet and the processing methods including designing, cutting, bending, CNC milling, surface finishing, thermoforming, printing, gluing. Today, we are providing integrated fabrication services to global clients.

The acrylic sheet is also called “plexiglass sheet” and “PMMA sheet”, it is one of the best materials to replace the glass. Because it offers many advantages than glass (difference between acrylic and glass). Therefore, it is used widely for the indoor and outdoor sign, POP display case, acrylic shelves, acrylic dome, acrylic furniture, and food and beverage industry, etc.

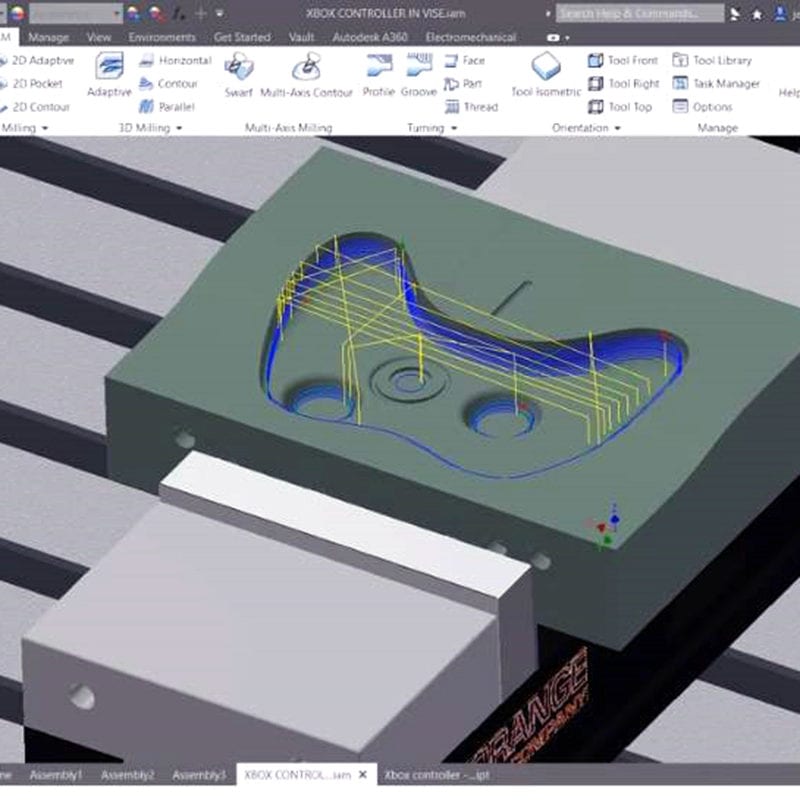

Designing Custom Acrylic

With the assistance of computer-aided design (CAD, Solidworks, UG), UVPLASTIC engineers can work with clients to design the acrylic part at the beginning, it offers precise modeling, cost optimization, quality output. Our experienced engineers can find the best fabrication solution.

Cut Custom Plexiglass Sheet

UVPLASTIC will use leaser and CNC cutting machines to cut acrylic to size according to different requirements, which offers the working area of 100” x 60” and can cut and polish more than 1” thick PMMA sheet. They can cut acrylic sheet to complicated shapes with high accuracy, it is chip-free edges without secondary machining.

The high-tech cutting equipment helps UVPLASTIC to find a very economical way to meet the client’s needs. The 5-axis cutting machine can finish cutting length, width and height, exceptional accuracy and cutting edge mechanisms.

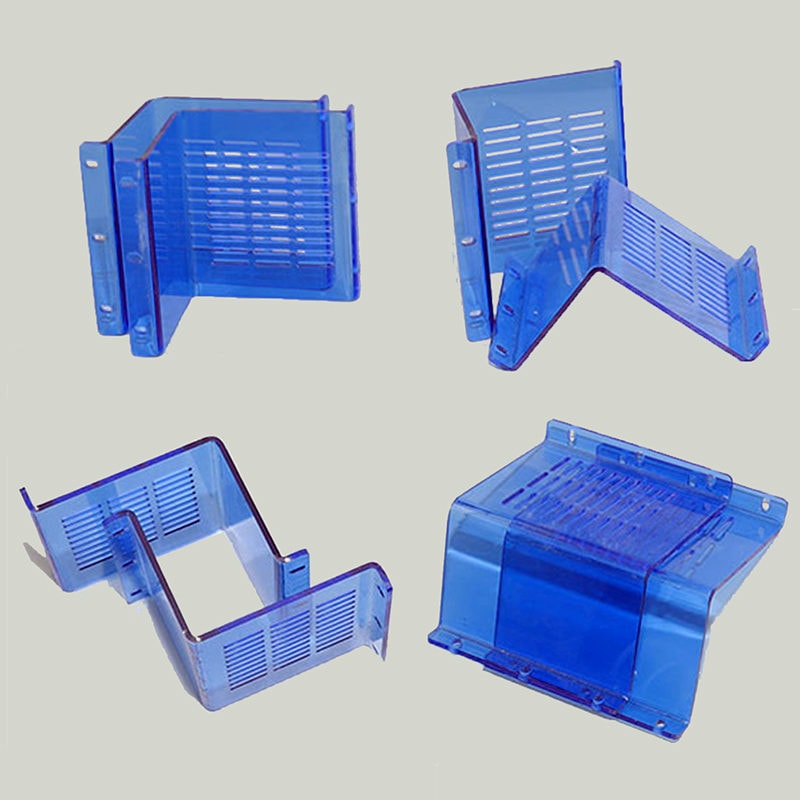

Custom Bending Acrylic

UVPLASTIC offers a hot bending method for acrylic sheets because cold bending is not suitable. The automatic heating bending equipment will offer the precise temperature setting and bend the PMMA sheet with the right angle and great surface. The bending length is up to 2.5m.

Custom Finishing Plexiglass

An acrylic product with an appropriate surface finishing will offer an eye-catching appearance, longer lifespan, and a specific function. The surface finishing methods that UVPLASTIC can provide are polishing, sanding, sandblasting.

Flame polishing is a good way to get the smooth and clear surface of the acrylic product. Sanding and sandblasting offer acrylic products with mysterious and privacy surface. Whatever surface type you want, UVPLASTIC always answers you with the right solution.

Want to know detail about polishing acrylic & sanding acrylic;

Custom Thermoforming Acrylic

Thermoforming is a great forming method for the complex-shaped and spherical acrylic products, including drape & oven forming, blow molding. They are great cost tooling, it also retains its surface features post-processing.

UVPLASTIC offers excellent thermoforming solutions, Max. Size is up to 5m x 2.5m

Custom Printing Acrylic

UVPLASTIC can offer excellent acrylic printing services including silkscreen printing and digital printing.

Custom Gluing Acrylic

There are a variety of glues, UVPLASTIC engineers can choose the right glue according to the application, size, environment, it offers excellent sealing property and wonderful surface. That will meed and exceed your expectations.

Custom Machining Acrylic

UVPLASTIC offers custom machining acrylic services from design to prototype building and quantity production. Today, we have provided more than 2000 acrylic products to global clients.