Top Anti Static Polycarbonate Manufacturer

Product Introduction

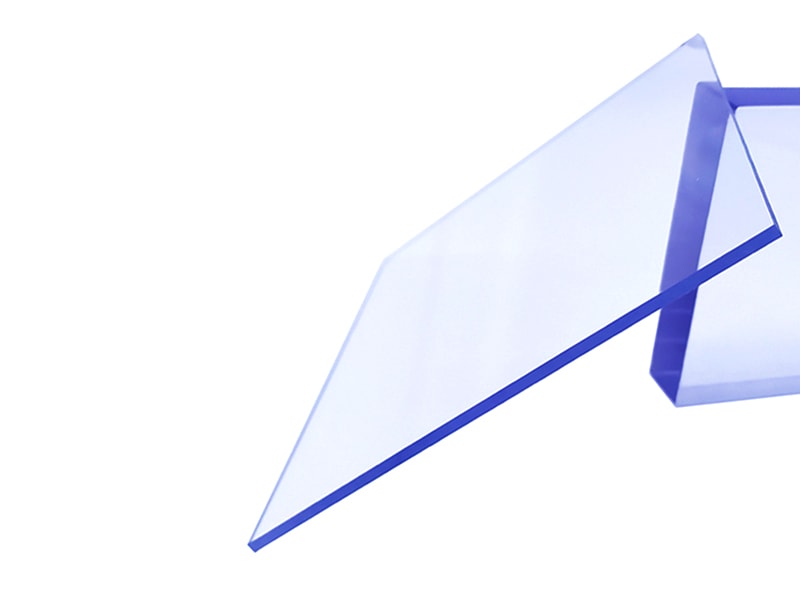

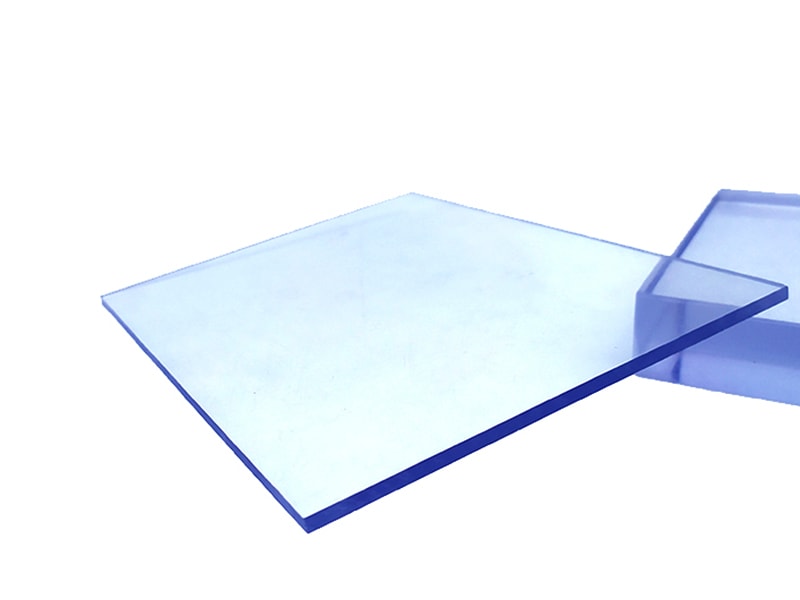

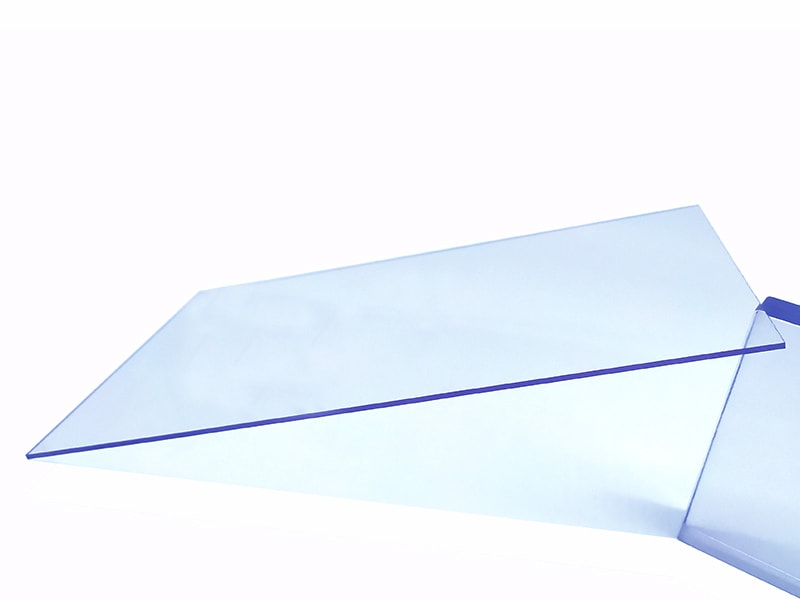

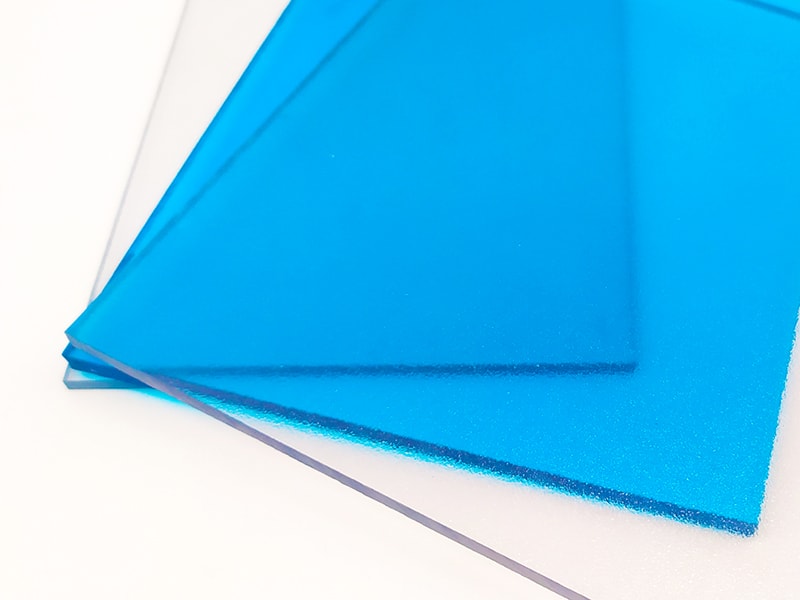

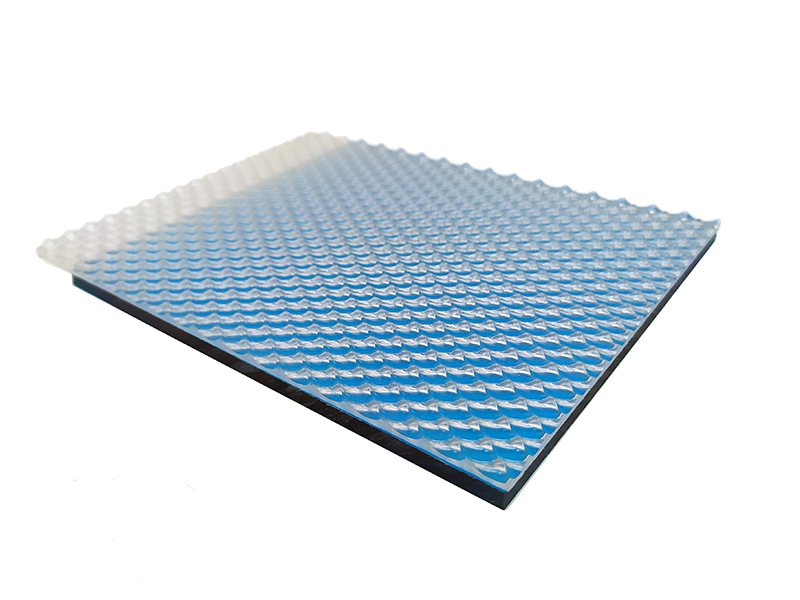

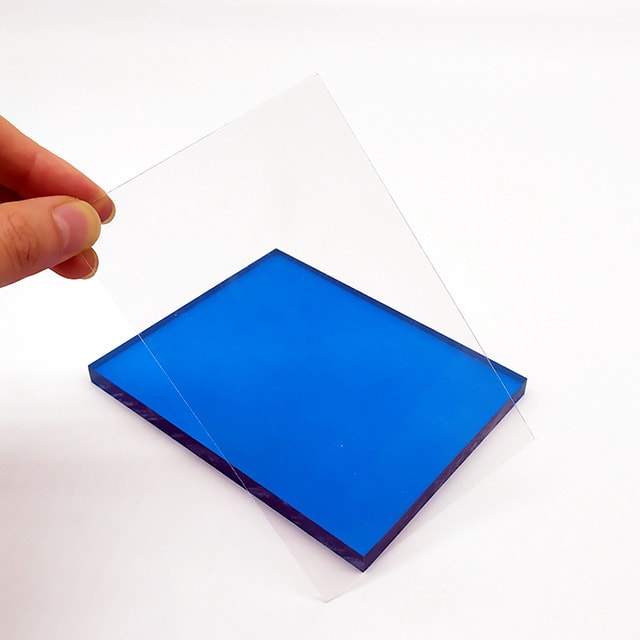

Anti Static Polycarbonate Sheet is coated with the electrostatic dissipative layer. The surface resistance is from 10^6 Ohms to 10^8 Ohms, therefore, it is effective to prevent and control generating the static electricity on the surface of the polycarbonate sheet. Anti Static polycarbonate is also known as “ESD Polycarbonate” and “electrostatic dissipative polycarbonate”.

The electrostatic dissipative coating is compound by plastic and metal. Therefore, the anti-static polycarbonate sheet is not affected by weather, humidity, and fog. Meantime, it offers superior impact and chemical resistance.

UVPLASTIC anti-static polycarbonate sheet is widely used in industrial areas, for example, the doors, windows, covers, and guards for the electronic equipment, assembly machines, instruments, conveyor line covers, transparent room partitions, process equipment, and automation equipment.

Product Specification

Standard Size

| Thickness (mm) | Standard Size (mm) | Raw Material |

|---|---|---|

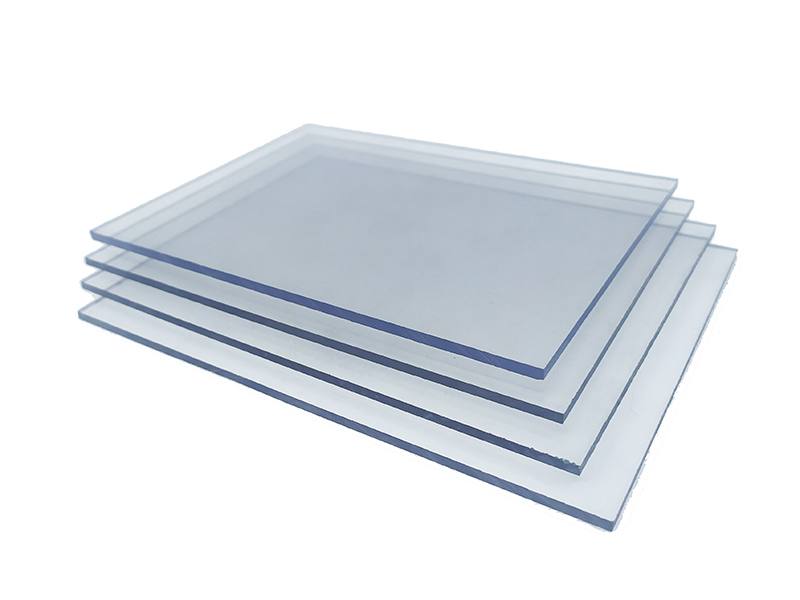

| 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm | 1000x2000mm, 1220x2440mm, Custom Size | Bayer, Sabic |

| Custom thickness | Custom Size | Bayer, Sabic |

- Custom Polycarbonate is available;

- It is free to cut polycarbonate to size according to clients’ requirement;

- Anti Static Acrylic is available;

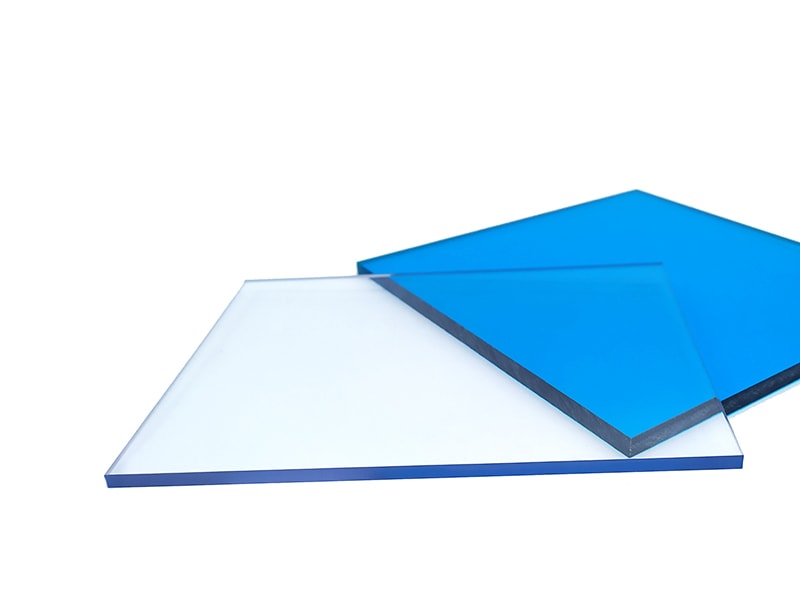

Color Description

| Type | Color Description |

|---|---|

| Transparent | Clear |

| Translucent | Brown, Bronze, Gary, Red, Blue, Green, yellow |

Physical Properties

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Model | / | / | UVFPC-ESD |

| Surface Resistance | ASTM D257-14 | Ohm | From 10^6 to 10^8 |

| Specific Gravity | ASTM D-792 | g/cm3 | 1.2 |

| Coefficient of Linear Thermal Expansion | ASTM D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | ASTM C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | ASTM D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | ASTM D-638 | MPa or N/mm² | >65 |

| Elongation at Break | ASTM D-638 | % | >100 |

| Tensile Modulus of Elasticity | ASTM D-638 | MPa | 2400 |

| Flexural Strength | ASTM D-790 | MPa | 100 |

| Deflection Temperature (264 psi load) | ASTM D648 | °F/°C | 275/135 |

| Vicat Softening Point | ASTM D1525 | °F/°C | 284/140 |

| Maximum Continuous Service Temperature | — | °F/°C | 190/87 |

| Maximum Discontinuous Service Temperature | — | °F/°C | 210/98 |

Default third-party testing organization is SGS

Application

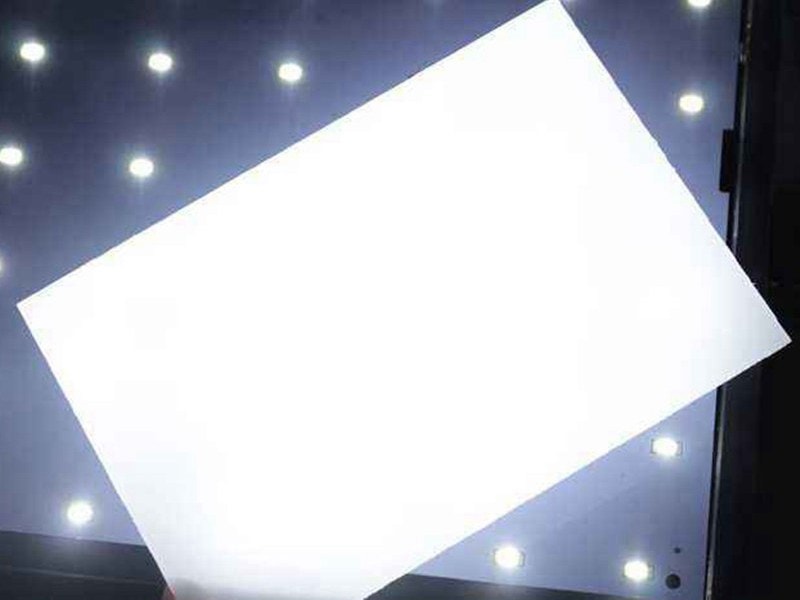

Anti Static Polycarbonate Sheet is designed to resist the tribocharging, it can’t generate an electrostatic when grounded properly. It can prevent the damage and quality defects caused by the electrostatic.

This plastic sheet is the right material for manufacturing and assembly working places where it is sensitive for electrostatic. Therefore, anti-static polycarbonate sheet is suitable for use in the micro-manufacturing, electronic, precision automation and semi-conductor industries.

The typical applications are windows, doors, guards, covers, operation panels for: