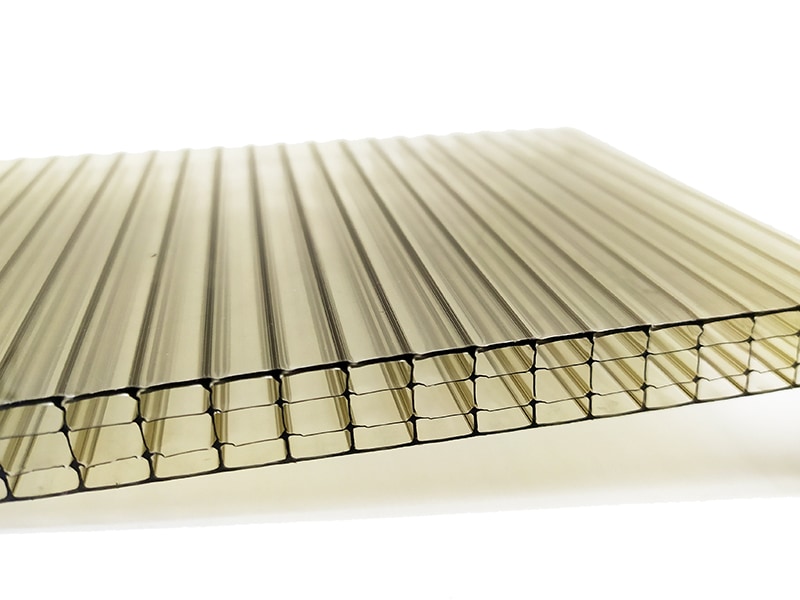

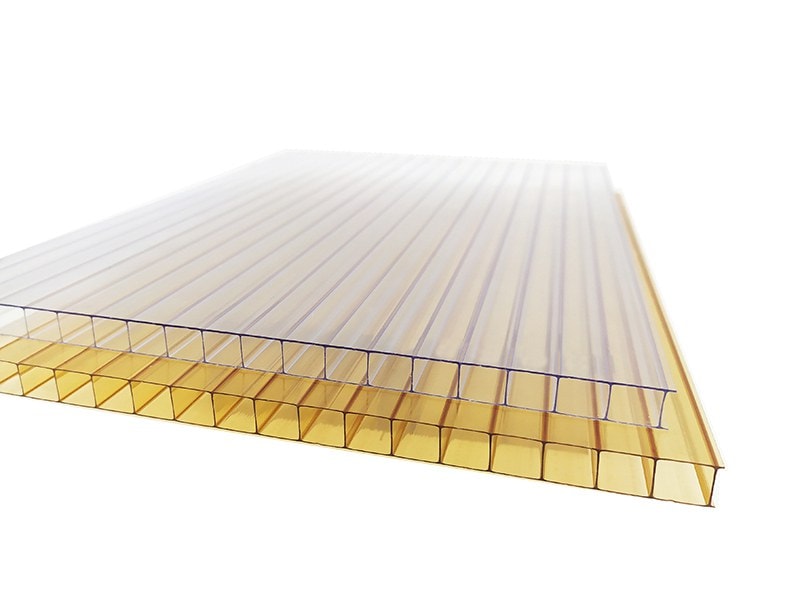

Five Wall Polycarbonate Sheet

Product Description

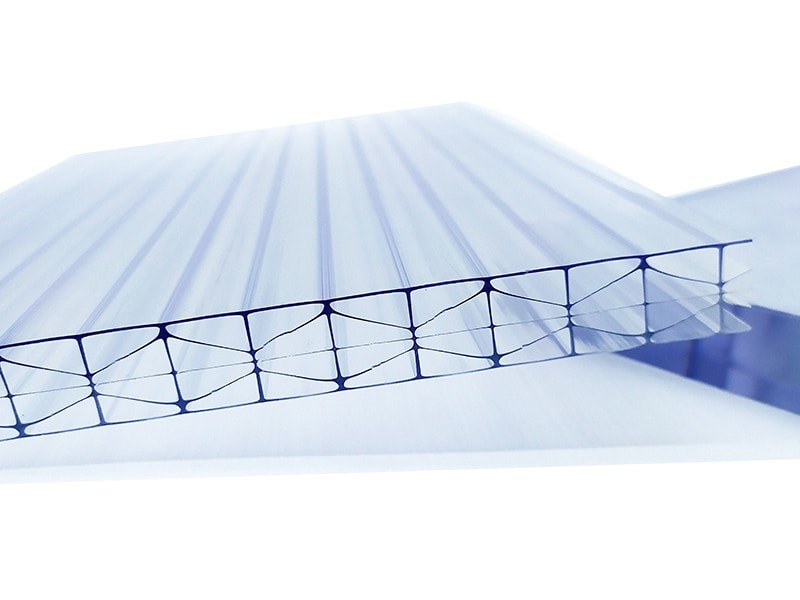

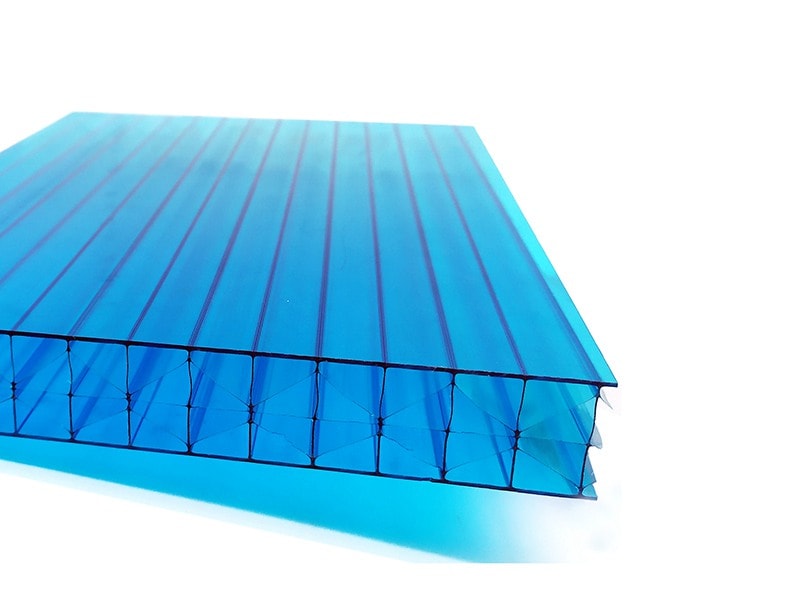

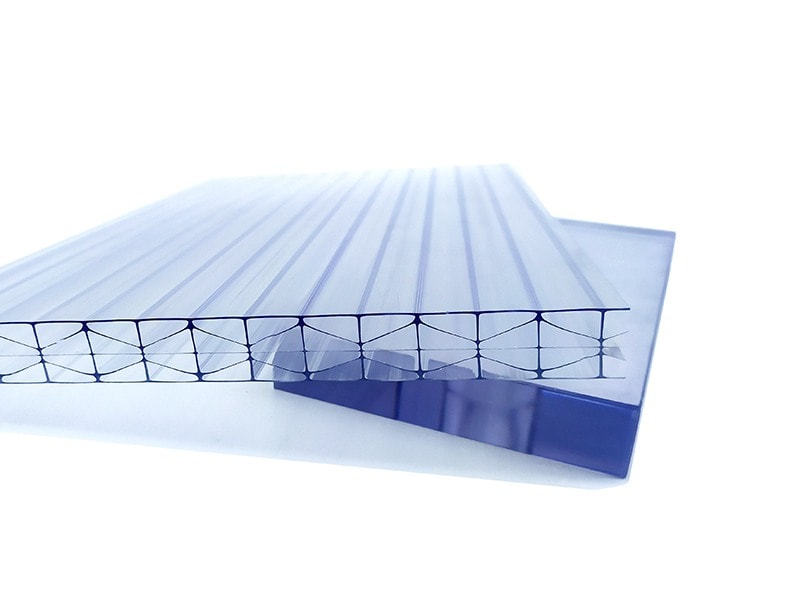

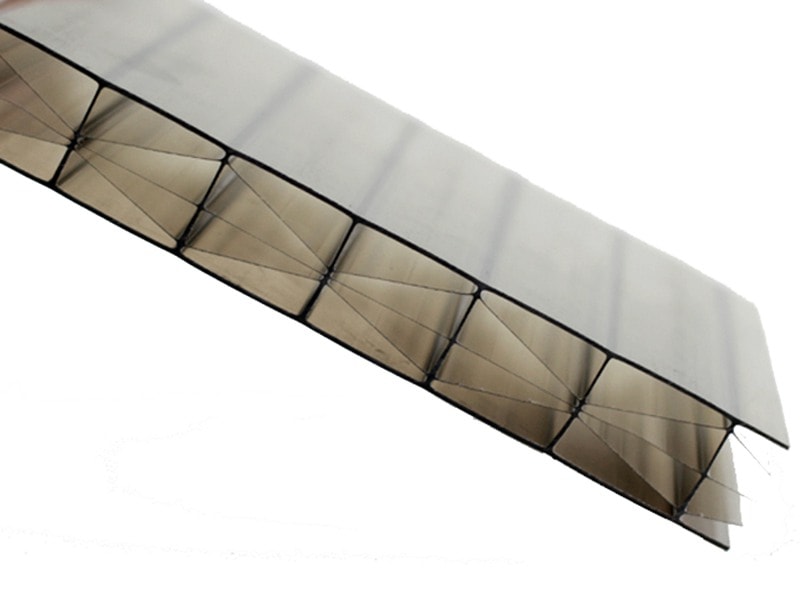

Five Wall Polycarbonate Sheet is the strongest and thickest roofing sheet in the multiwall polycarbonate family. It has an X type profile and five walls structure. Therefore, five wall polycarbonate sheet offers a significant improvement in thermal insulation properties over double-wall and four wall polycarbonate sheets, but it is a minimal drop at the light transmission.

With the good light transmission, high impact resistance, great heat resistance, and hail resistance and high thermal insulation values, it is the right material for application where superior thermal insulation properties are required at a little upcharge.

Product Specification

| Model | Thickness | U-Value (W/m²·°K) | Light Transmission, clear, % | Width 700 (mm) | Width 1050 (mm) | Width 2100 (mm) |

|---|---|---|---|---|---|---|

| UVMPC-FI-18 | 18 mm | 1.9 | 64 | ✔ | ✔ | ✔ |

| UVMPC-FI-20 | 20 mm | 1.7 | 63 | ✔ | ✔ | ✔ |

| UVMPC-FI-22 | 22 mm | 1.5 | 62 | ✔ | ✔ | ✔ |

| UVMPC-FI-24 | 24 mm | 1.25 | 60 | ✔ | ✔ | ✔ |

| UVMPC-FI-25 | 25 mm | 1 | 58 | ✔ | ✔ | ✔ |

| UVMPC-FI-30 | 30 mm | 0.85 | 56 | ✔ | ✔ | ✔ |

- Other Typical Dimensions are available, such as 4×8 ft, 2x3m;

- Machining polycarbonate is available;

- It is free to cut polycarbonate to size according to clients’ requirement;

- Want to know more about polycarbonate sheet;

| Model | Description |

|---|---|

| UVMPC-FI-U1 | Standard five wall with the co-extruded UV protective layer on one side |

| UVMPC-FI-U1A | Standard five wall with the co-extruded UV protective layer on the outside, anti fog coating on the inside |

| UVMPC-FI-U2 | Standard five wall with the co-extruded UV protective layers on two sides |

| Model | Clear | Bronze | White Opal | Green | Blue | Custom Color |

|---|---|---|---|---|---|---|

| UVMPC-FI-18 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FI-20 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FI-22 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FI-24 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FI-25 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FI-30 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Light transmittance | D-1003 | % | >76 |

| Heat deflection temperature (HDT) | D-648 | °C | 140 |

| Service Temperature – Short term | °C | -50 to +120 | |

| Service Temperature – Long term | °C | -40 to +100 | |

| Impact falling dart | ISO 6603/1 | J | 40-400 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Practical thermal expansion/contraction | mm/m | 3 |

Default third-party testing organization is SGS

Commercial Greenhouse

With the outstanding thermal insulation performance, lighter weight, high light transmittance and the great performance between -40℃ and 120℃, the multiwall polycarbonate sheet is the ideal material for the commercial greenhouse.

Want to know how use polycarbonate panels for greenhouse.

With the excellent impact resistance, five wall polycarbonate sheet is the best choice for stadium roofing, even under the storm, hailstone, heavy snowfall, sandstorm, hurricane weather, and intense ultraviolet condition.

Skywalks Roof