Leading Supplier of Flame Retardant Polycarbonate Sheet In China

Product Description

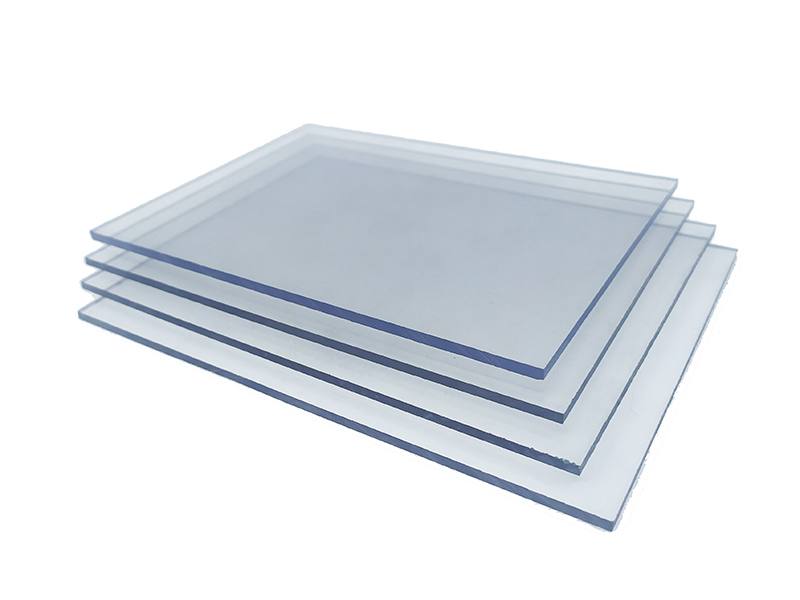

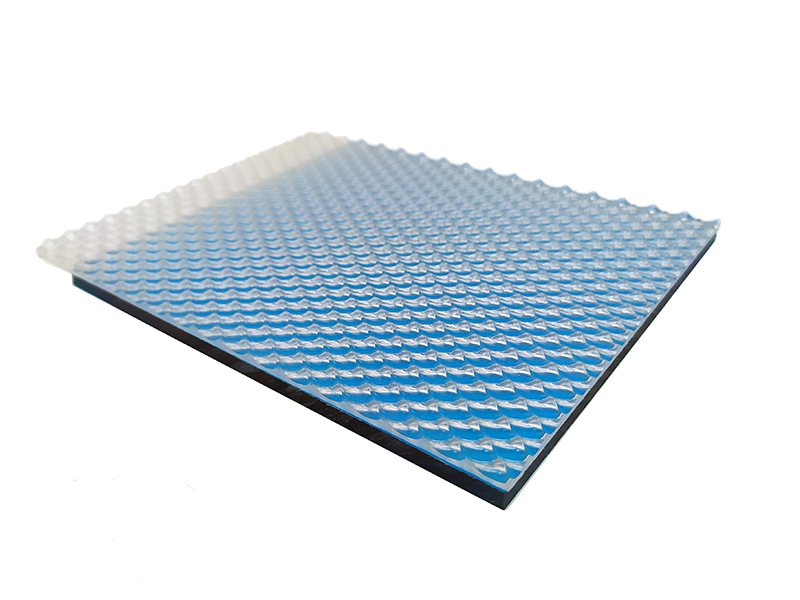

Flame Retardant Polycarbonate Sheet offers the improved fire retardant property and heat deflection characteristics over the standard polycarbonate sheet. It meets the flammability codes of the engineering industry, construction industry, transportation industry, such as ASTM E84, UL94, GB/T2408-2008, and UL723, etc. Some people call it Fire Resistant Polycarbonate and Fireproof Polycarbonate.

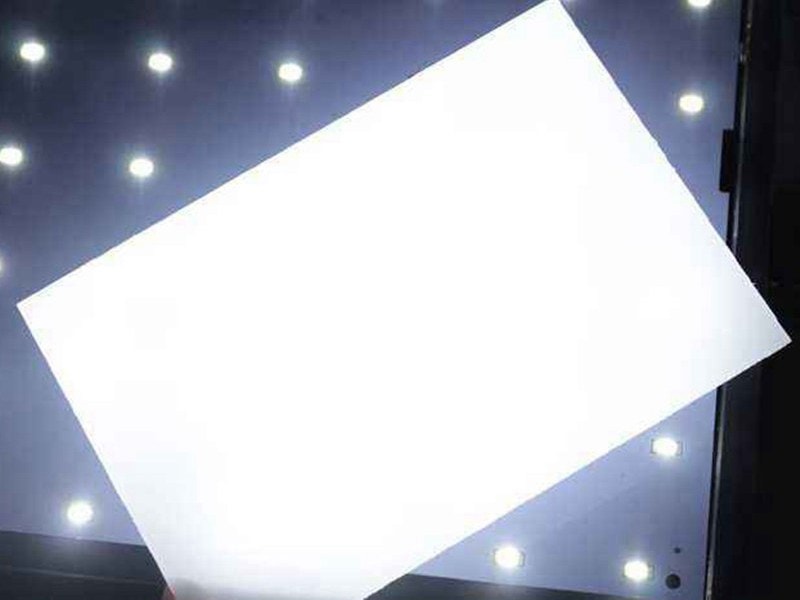

UVPLASTIC Flame Retardant Polycarbonate Sheet offers high clarity and surface quality. It is virtually unbreakable with extremely high impact resistance. In case of fire, the flame retardants can reduce the growth of fire in a very short time. It is the right material for industrial parts, electrical components, a wide variety of vehicles, a train seat that is requiring flame retardance, and the most application that glass is used.

Products Specification

Model & Standard Dimensions

| Thickness (mm) | Width (mm) | Length (m) | Packaged as Panel | Packaged as Roll |

|---|---|---|---|---|

| 1mm, 1.5mm | 1000, 1220, 2100, 2650 | 2.44, 5.8, 12, 30, 40 | ✔ | ✔ |

| 2mm | 1000, 1220, 2100, 2650 | 2.44, 5.8, 12, 30 | ✔ | ✔ |

| 2.5mm, 3mm | 1000, 1220, 2100, 2650 | 2.44, 5.8, 12, 20 | ✔ | ✔ |

| 4mm, 5mm, 6mm, 8mm, 10mm | 1000, 1220, 2100, 2650 | 2.44, 5.8, 12 | ✔ | |

| 8mm, 10mm, 12mm, 15mm | 1000, 1220, 2100, 2650 | 2.44, 5.8, 12 | ✔ | |

| 16mm, 18mm, 20mm | 1000, 1220, 2100 | 2.44, 5.8 | ✔ |

Note:

- Custom Polycarbonate is available;

- Polycarbonate cut to size according to clients’ requirement;

- Thin polycarbonate sheet is called polycarbonate films (0.125mm to 1mm thickness), they are available;

Product Range

| Model | Description |

|---|---|

| UVFPC-FL | Stabilized UV coating layer for general purpose |

| UVFPC-FL-U1 | Co-extruded UV protective layer on the exterior surface for outdoor applications |

| UVFPC-FL-U1A | Co-extruded UV protective layer on the exterior surface, anti-condensation treatment on the internal surface for outdoor application |

| UVFPC-FL-U2 | Co-extruded UV protective layer on both surfaces for outdoor application |

Physical Properties

| Physical Property | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Fire rating | UL 94 | / | V0 |

| Fire rating | ASTM E84 | / | Class B or Class A |

| Light transmittance | D-1003 | % | From 80% to 91% |

Default third-party testing organization is SGS;

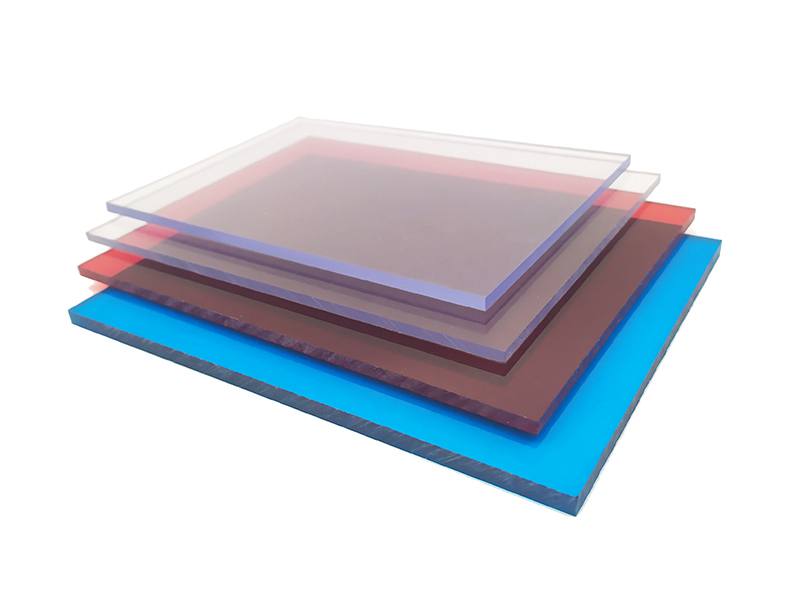

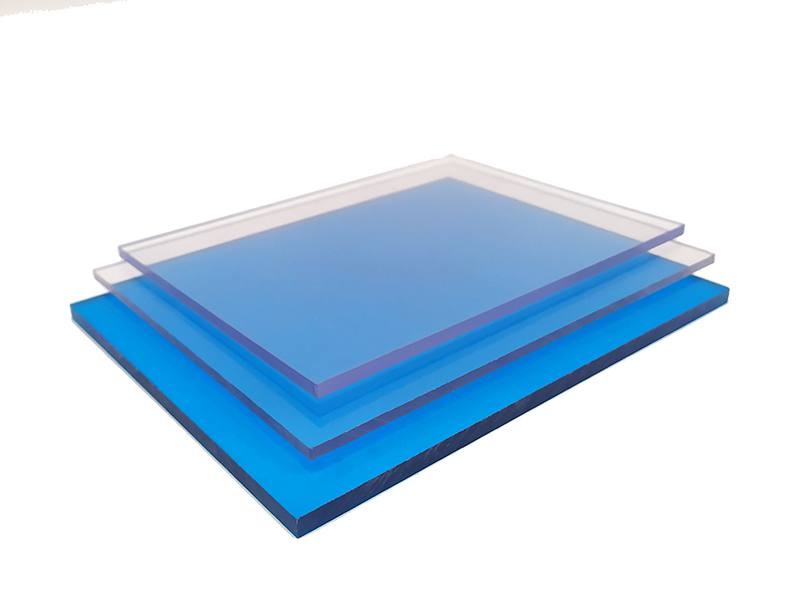

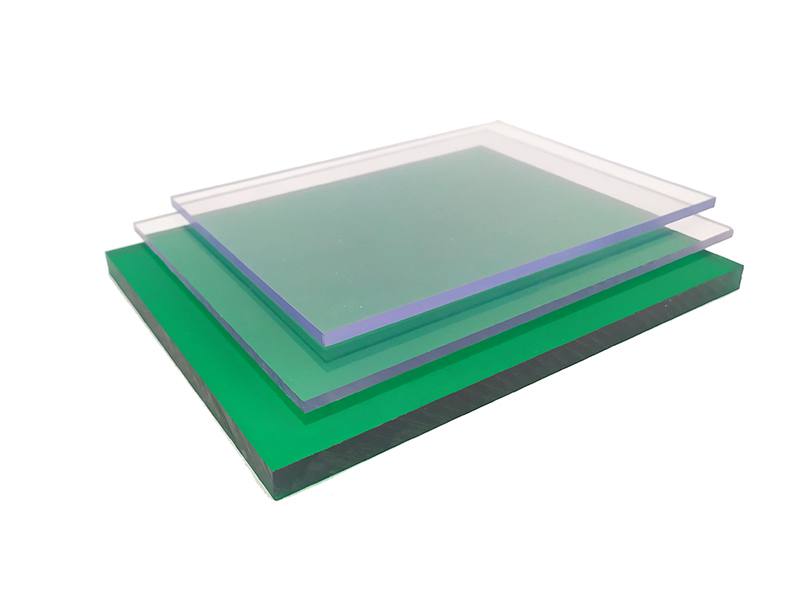

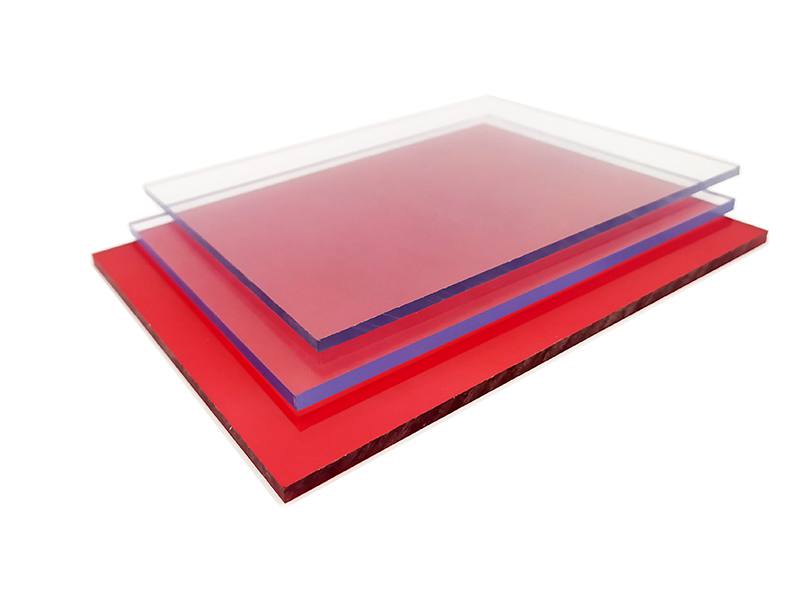

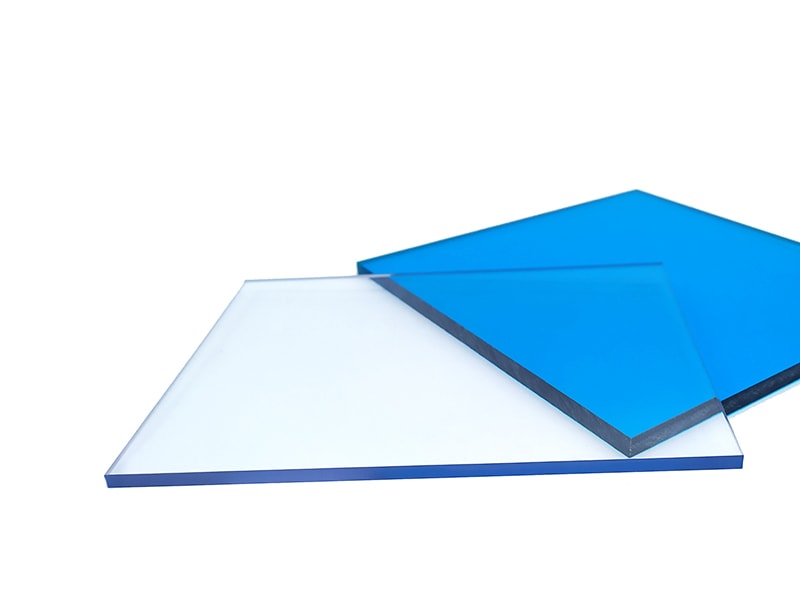

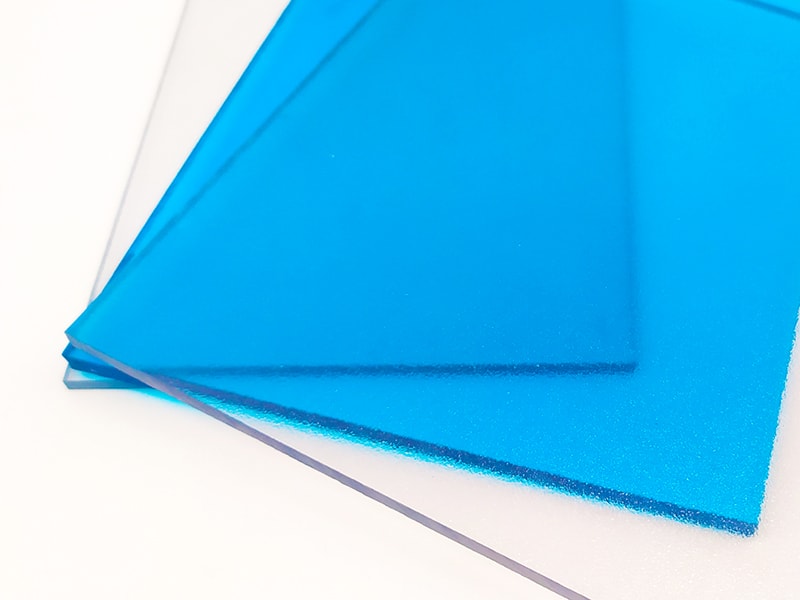

Product Color

| Type | Colors Description |

|---|---|

| Transparent | Clear, Bronze, Brown, Gary, Red, Lighter Blue, Lighter Green |

| Translucent | Black, Opal White, Blue, Green |

| Opaque | Black, Opal White, Yellow, Dark Blue, Red, Dark Grey, Dark Brown |