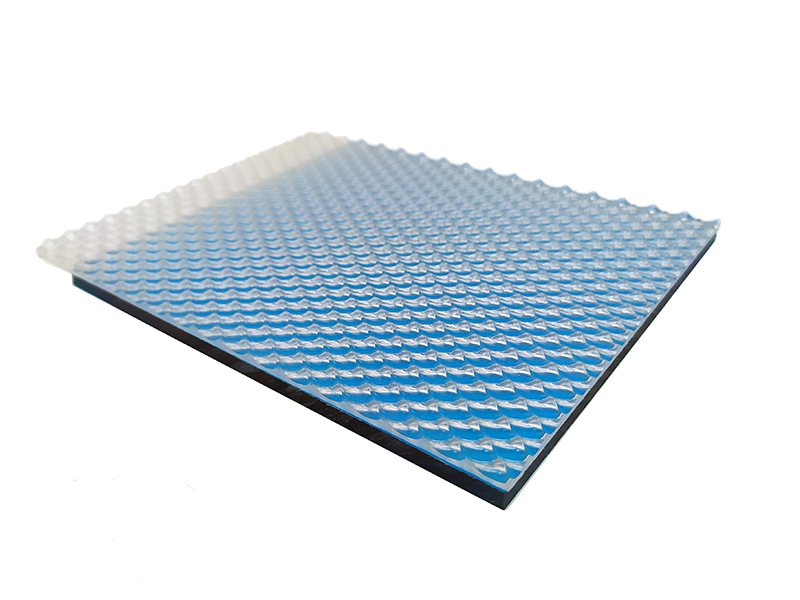

Polycarbonate Light Diffuser Panel

Product Description

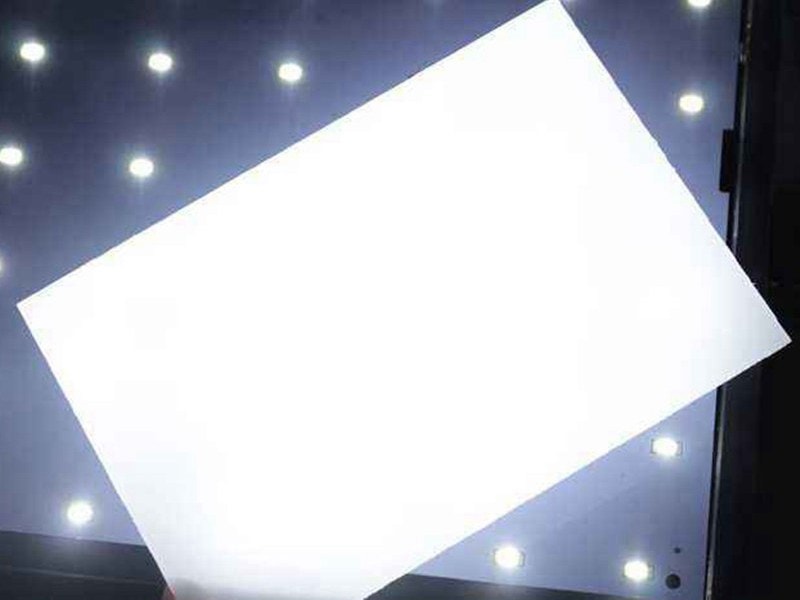

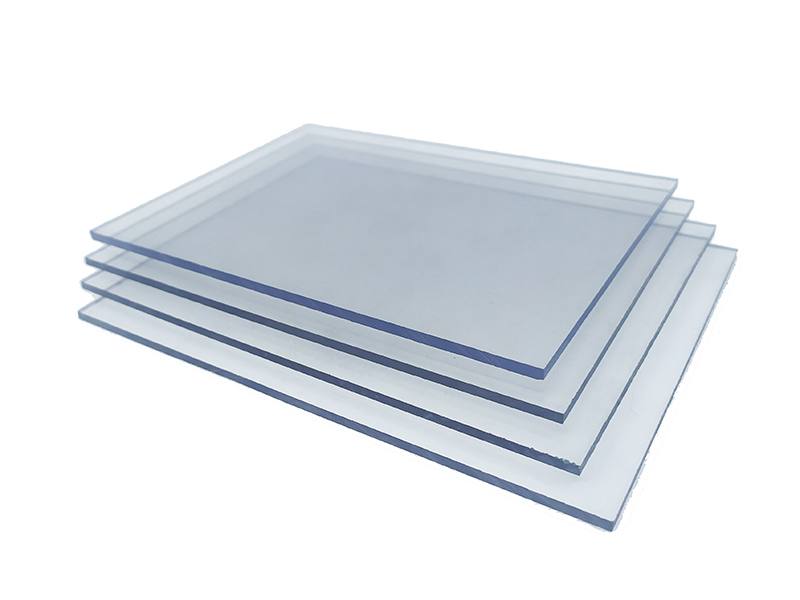

Polycarbonate Light Diffuser Panel is an efficient and excellent light diffuser material, which is mainly used as the cover of the LED Light, DIY light, office lamp, kitchen light, fluorescent light. Polycarbonate Light Diffuser Panel can scatter light spots equably on the surface, then, you can get soft and comfortable light rays. It is also known as “LED light diffuser”, “polycarbonate diffuser” and “plastic light diffuser”.

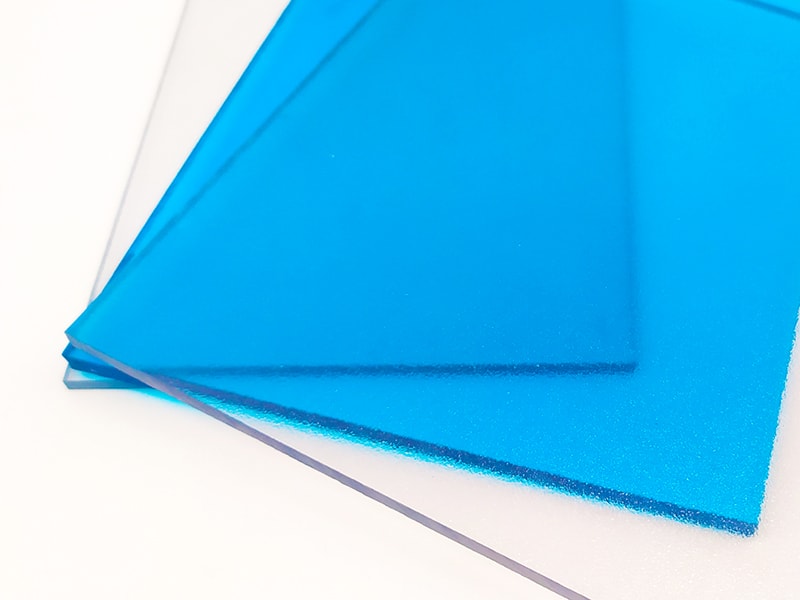

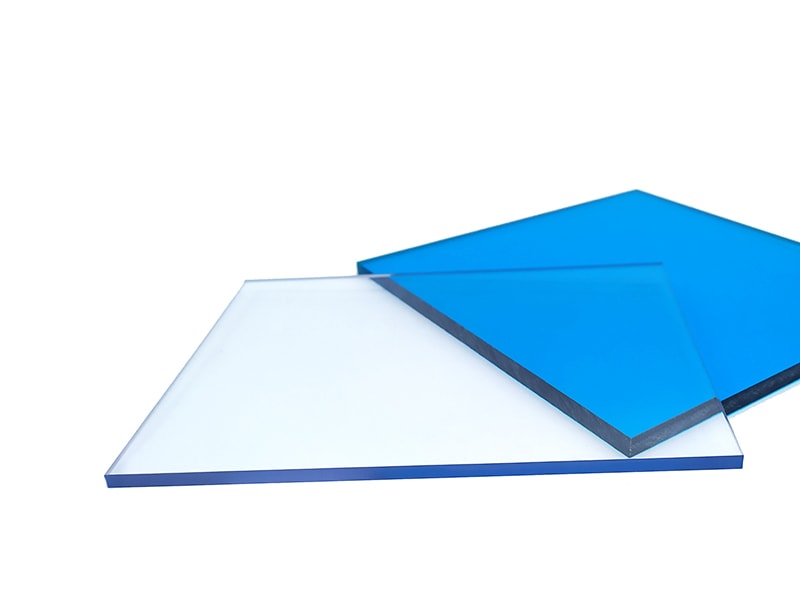

UVPLASTIC has developed opal and colored light diffuser panel, and matte surface polycarbonate LED diffuser, texture polycarbonate diffuser. The thickness ranges from 1.5mm to 6mm. Otherwise, UVPLASTIC can provide polycarbonate diffuser sheets with customized colors, customized sizes, and customized shapes.

Product Specification

Product Description

| Item | Description |

|---|---|

| Product Name | Polycarbonate Light Diffuser Panel, LED light diffuser, polycarbonate Diffuser |

| Raw material | High-quality Polycarbonate |

| Standard Color | White, Opal, Custom Color |

| Thickness | 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm |

| Standar Width | 915mm, 1000mm, 1220mm, 2100mm, Custom Width |

| Standard Length | 1000mm, 2400mm, 5800mm, 11800mm, Custom Length |

| Working Temperature | From -40 degree centigrade to 120 degree centigrade |

| UV Protective Layer | Optional |

| Anti fog Founction | Optional |

| Fire Rating | V2, V0 according to UL94 |

Note:

- Custom sizes are available;

- Free polycarbonate cut to size;

- OEM Polycarbonate services are available;

- LED light diffuser film is available;

- Want to know acrylic diffuser sheet;

Physical Properies

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Water Absorbing Capacity | 0.3 | % | ASTM D570 |

| Mechanical Property | Testing Method | Unit | Value |

| Elongation at Break | D-638 | % | >100 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Deflection Temperature (264 psi load) | ASTM D648 | °F/°C | 275/135 |

| Vicat Softening Point | ASTM D1525 | °F/°C | 284/140 |

| Maximum Continuous Service Temperature | — | °F/°C | 190/87 |

| Maximum Discontinuous Service Temperature | — | °F/°C | 210/98 |

| Flammability | UL94 | / | V-2 |

| Light transmittance | D-1003 | % | 65-85 |

| Haze | D-1003 | % | <0.5 |

Testing Method Notes:

- Default third-party testing organization is SGS;

- Other testing methods are acceptable besides ASTM standard;

| Model | Description |

|---|---|

| UVFPC-DI | Stabilized UV protective layer for general purpose |

| UVFPC-DI-U1 | Co-extruded UV protective layer on one side for outdoor application |

| UVFPC-DI-U1A | Co-extruded UV protective layer on the outside, anti-condensation treatment on inside for outdoor application |

| UVFPC-DI-U2 | Co-extruded UV protective layer on both sides for outdoor application |

Features

Application

- Lighting fixtures;

- LED light cover;

- Billboard or advertisement board;

- Lamp diffuser cover;

- DIY light diffuser;

- Kitchen fluorescent lights;

- Office light;

- Machine vision systems;

- Commercial lighting;

- School lamp;

- Fluorescent light diffuser;