Integrated Polycarbonate Fabrication Service

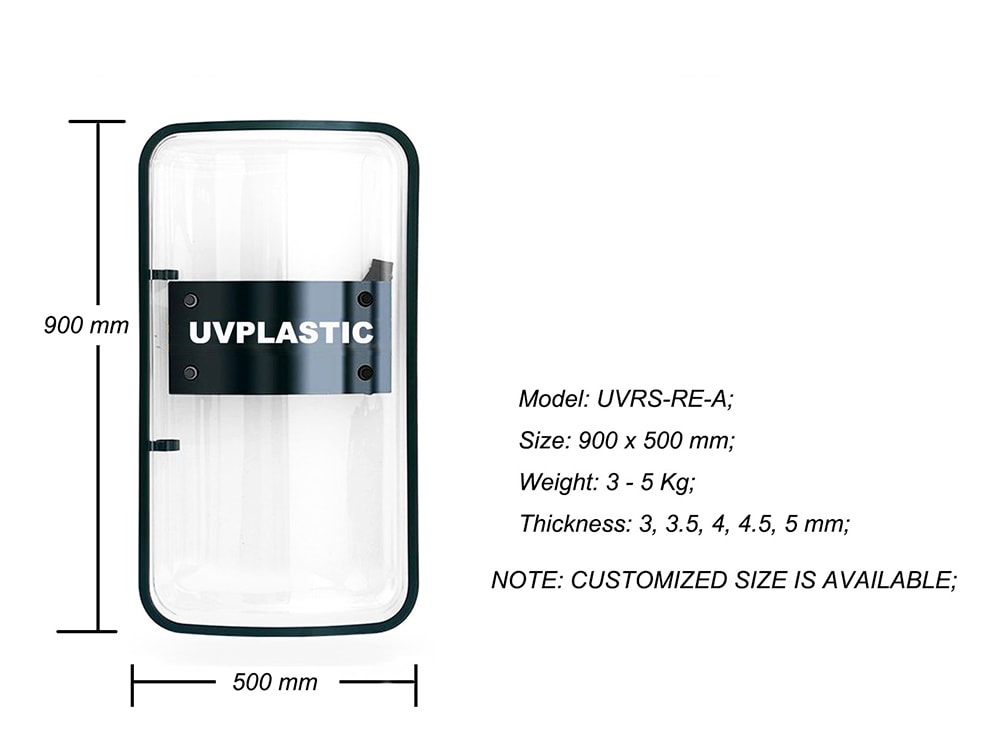

With more than 15 years of experience in machining polycarbonate, UVPLASTIC has been the best supplier of Custom Polycarbonate, and provide the integrated polycarbonate fabrication solution for all polycarbonate products including helmet visor, medical face shield, eye shield, police shield, car headlight, windshield, safety shield, goggle lens, skylight dome, which is used for the architecture, medical industry, aircraft, sign&display, electric industry, automation, etc.

We will provide the following fabrication methods and coating methods for the special requirements of polycarbonate parts for your projects.

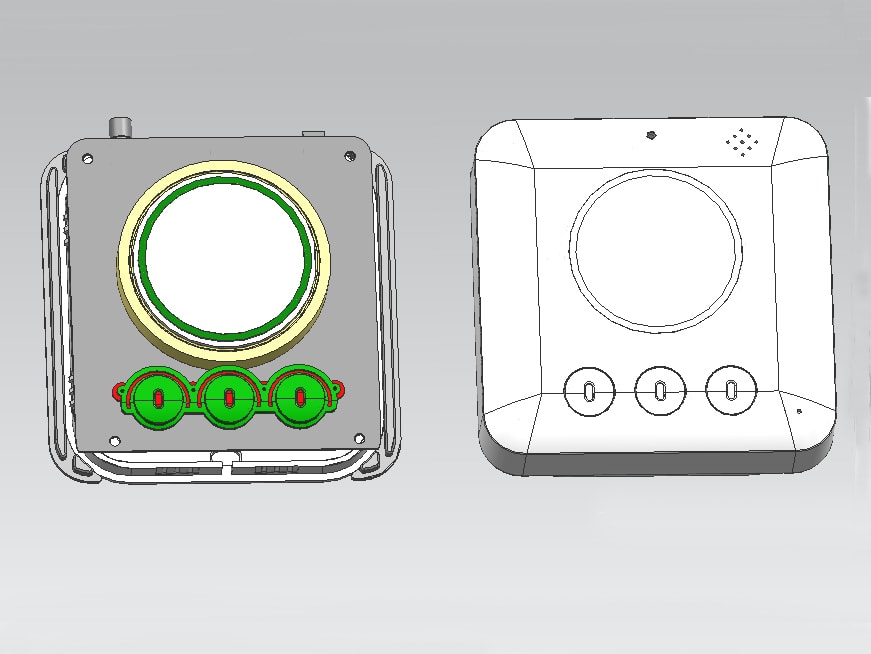

Designing Polycarbonate

With the help of computer-aided design (CAD), Solidworks, CATIA, and UG, UVPLASTIC engineers build a 2D and 3D model with precise size and shape of polycarbonate parts on the computer, it can reduce the designing defects at the very beginning.

UVPLASTIC has more than 30 engineers to support the clients from the design stage to the project ending stage. They can help you find the best fabrication solution for polycarbonate parts for your coming project.

Building Polycarbonate Prototype

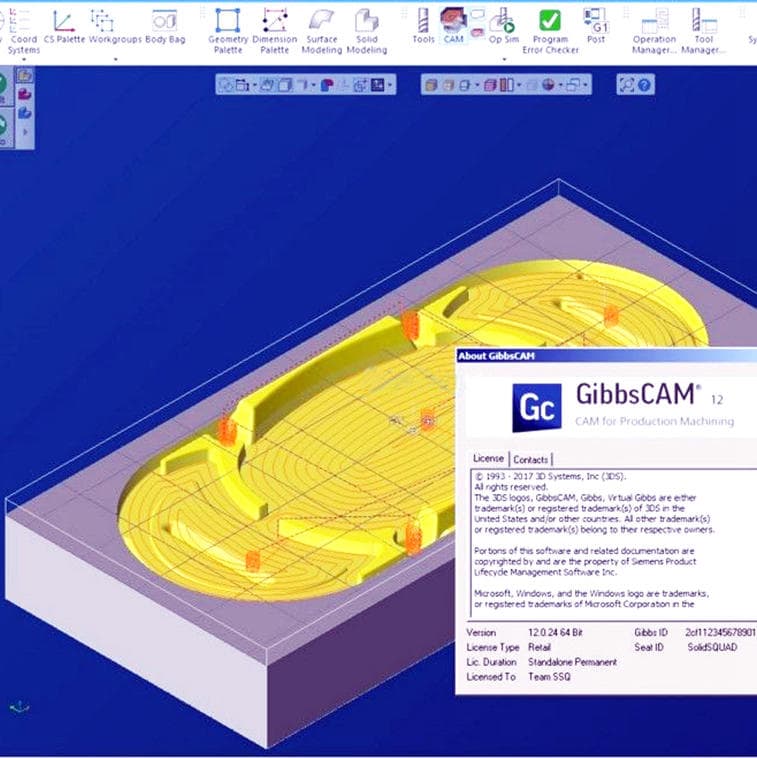

With the assistance of computer-aided manufacture (CAM) and 3D printing technology, UVPLASTIC can build a prototype at the beginning stage of your project. It is the best method to save time and cost.

Then, UVPLASTIC will manufacture a great wooden mold to manufacture in a small quantity, for example, 200 pcs, or 500 pcs. Because wooden mold will be the best cost-effective when the quantity is under 500 pcs.

If clients need more quantity, we will manufacture an aluminum mold. Because aluminum mold offers a longer lifespan. This mold will be the right choice when the quantity is more than 500 pcs.

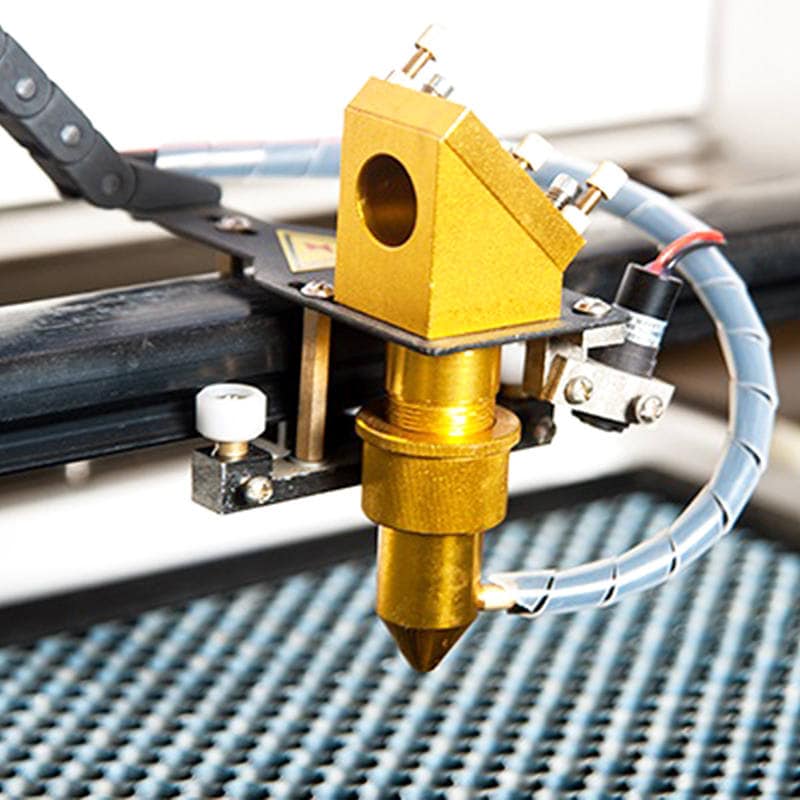

Cutting Polycarbonate

UVPLASTIC provides different solutions for cutting polycarbonate. Whether you want to cut polycarbonate films with 0.05mm thickness or polycarbonate sheets with 20mm thickness, or it is a supersize polycarbonate with high precision, UVPLASTIC always finds the best cutting solution for you. UVPLASTIC offers you the right cutting methods.

Cutting Method

category of polycarbonate sheets

cutting capabilities

| Items | Metric system | British system |

|---|---|---|

| Min. Thickness | 0.02mm | 0.001 inch |

| Max. Thickness | 25mm | 1 inch |

| Max. Length | 5m | 196 inches |

| Max. Width | 2.5m | 83 inches |

| Min. Tolerance | ±0.05mm | ±0.002 inches |

Polycarbonate Coating

UVPLASTIC can do coating layer on the surface of your polycarbonate parts for some specific function and longer lifespan, including:

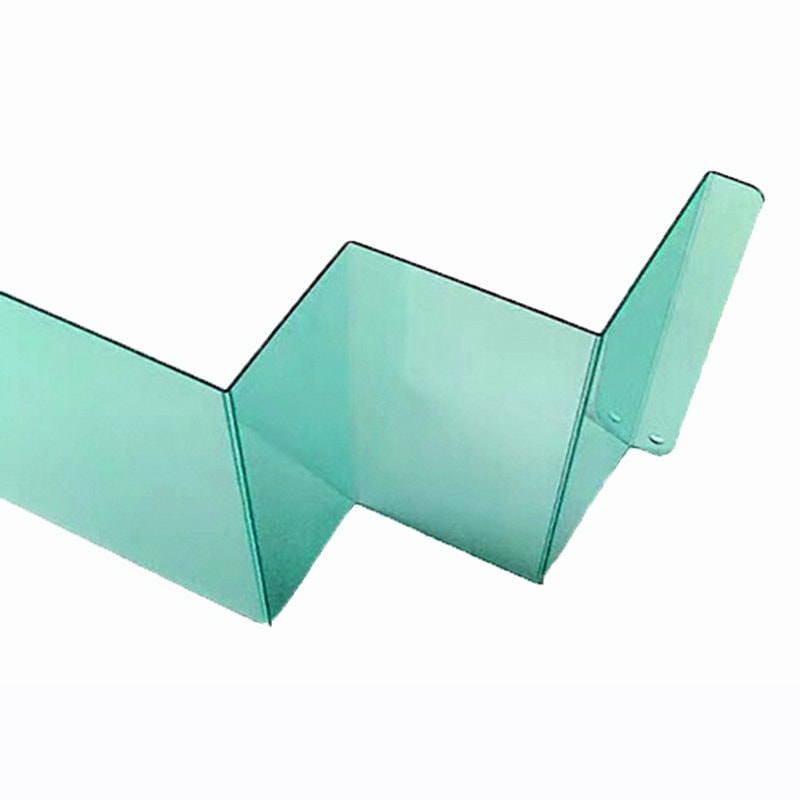

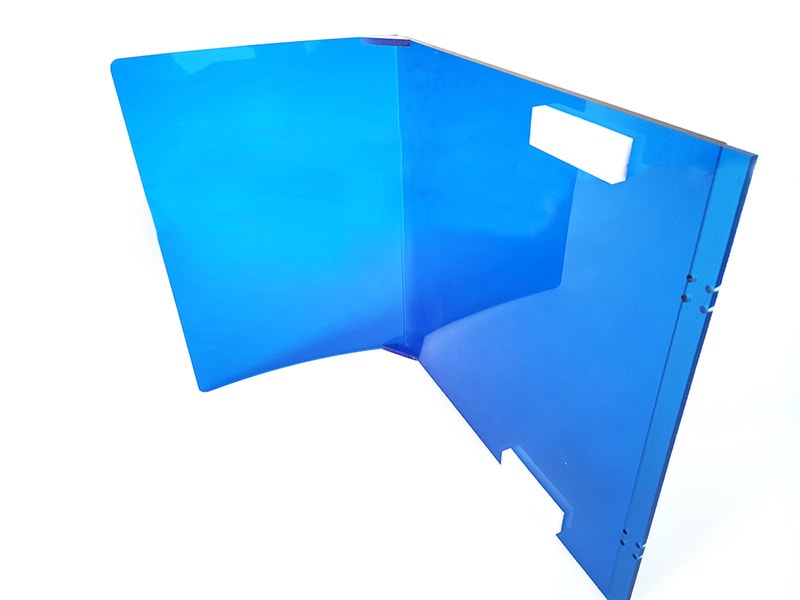

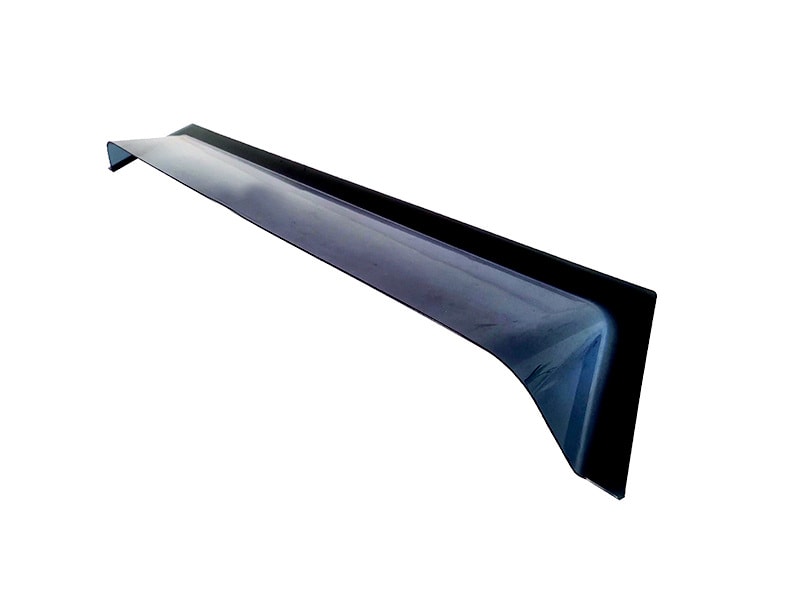

Bending Polycarbonate

UVPLASTIC will provide the best solution for bending polycarbonate sheets, including cold bending, heat-bending, and V-groove Bending. You just tell us the requirement of polycarbonate bending, our engineer will choose the right bending method;

Max. Bending Length is 7.8m (25ft).

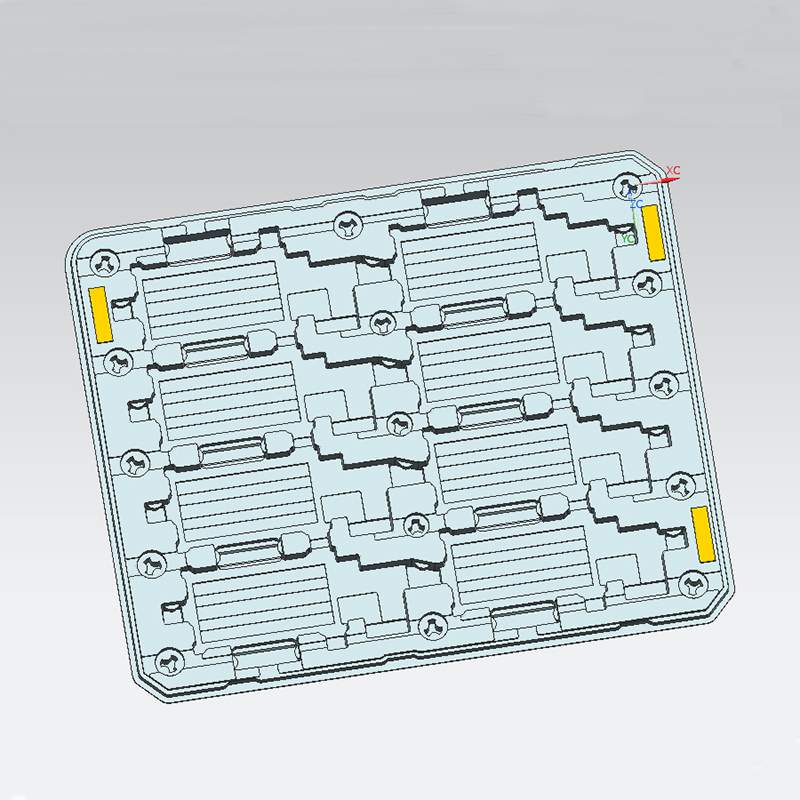

CNC Polycarbonate

The best CNC machine is necessary to mill polycarbonate, UVPLASTIC has five-axis CNC machinery, and provide the perfect solution of CNC polycarbonate with very tight tolerance.

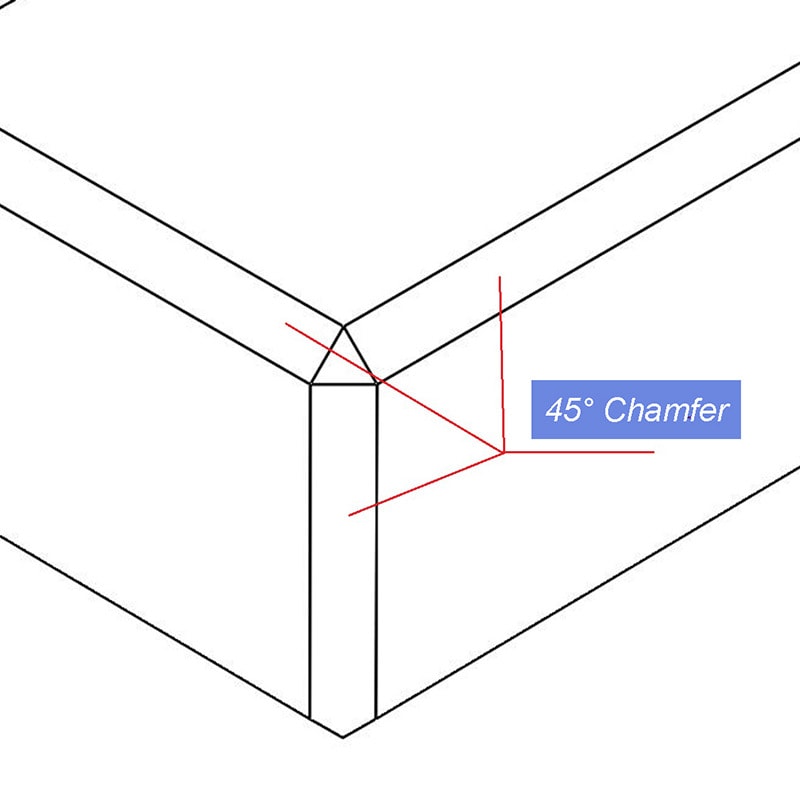

Edge Finishing

Edge finishing is one of the most fabrication processing, which will affect safety and appearance. UVPLASTIC offers a variety of edge options for polycarbonate parts, including

Surface Finishing

A plastic product with an appropriate surface finishing will offer an eye-catching appearance, longer lifespan, and a specific function. UVPLASTIC can offer you with buffing polishing, mechanical polishing, sanding surface, etc.

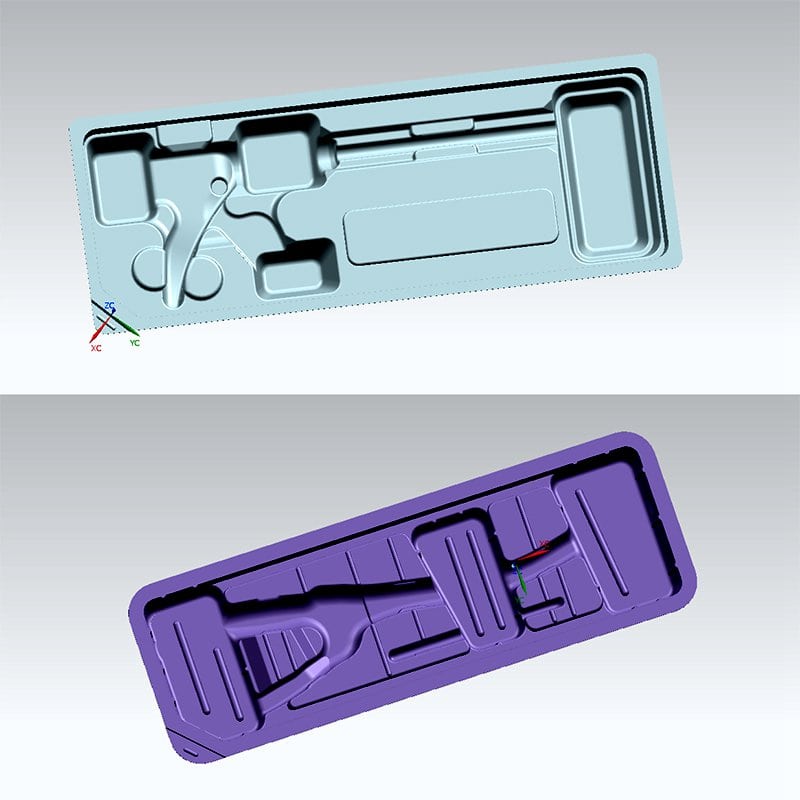

Thermoforming Polycarbonate

For polycarbonate parts with complex shapes, thermoforming fabrication will help you, we can thermoform solid polycarbonate sheet, twin wall polycarbonate sheet, thin polycarbonate sheet, embossed polycarbonate sheet, LED diffuser sheet.

UVPLASTIC can offer you vacuum forming, compression molding, oven forming for different polycarbonate products, including polycarbonate dome, riot shield, bubble tent, clear kayak, lampshade, etc.

We can provide you polycarbonate thermoforming service with Max. size of 5×2.5m (16×8 ft).

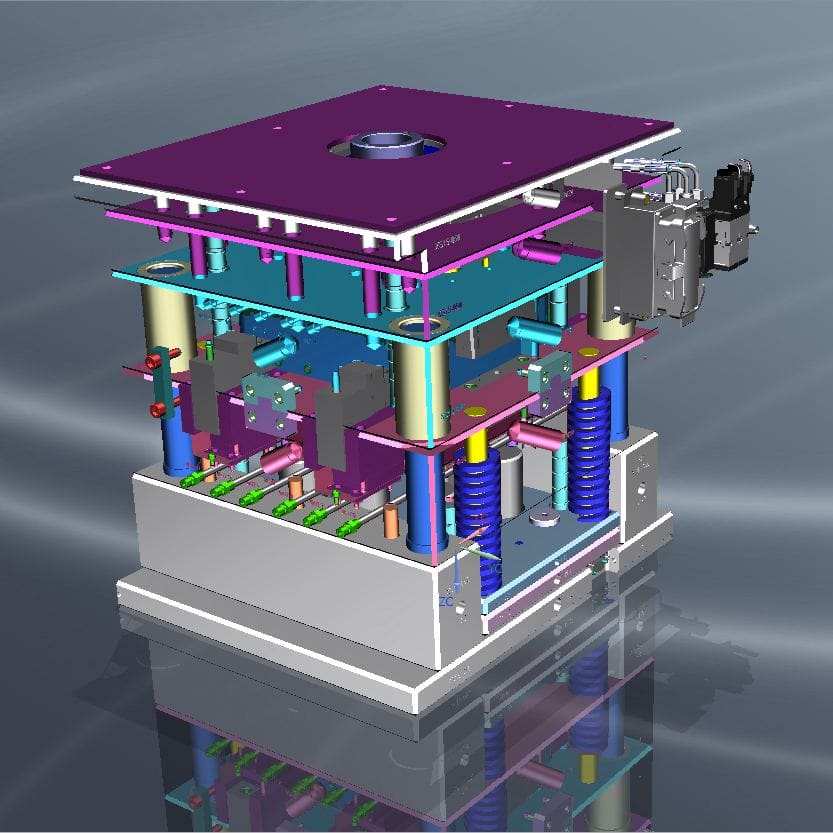

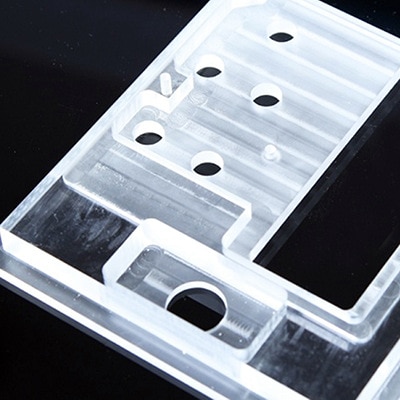

Polycarbonate Injection Molding

For small size and large quantities of polycarbonate parts, UVPLASTIC will choose polycarbonate injection molding to you, including optical polycarbonate parts.

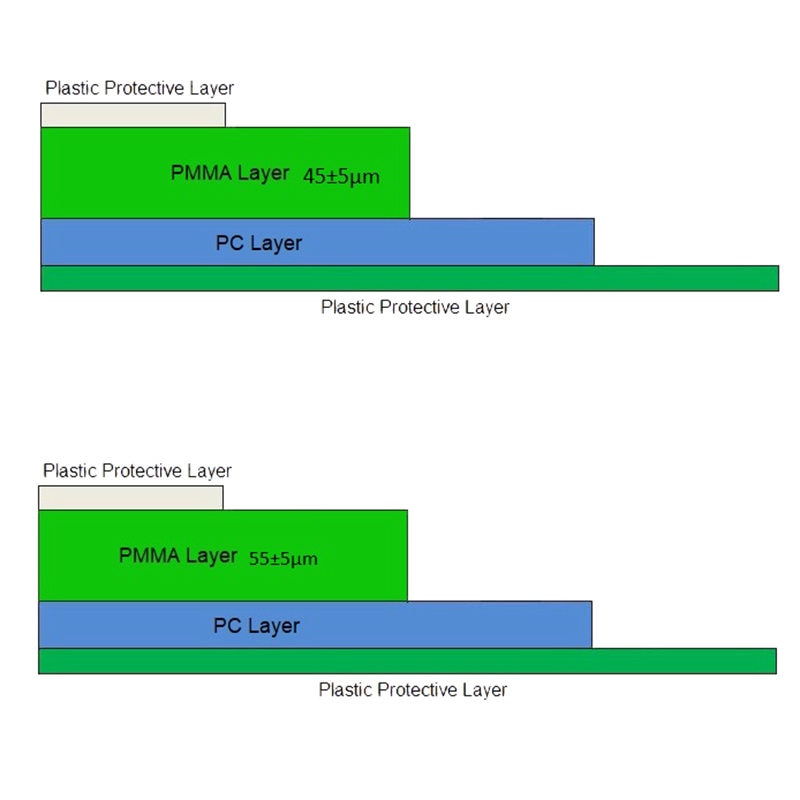

Polycarbonate Laminating Film

Polycarbonate laminating film is a thin polycarbonate sheet with PC/PMMA, the thickness from 0.05mm to 1mm.

Polycarbonate laminating film is used widely for screen and back cover applications including mobile phones.

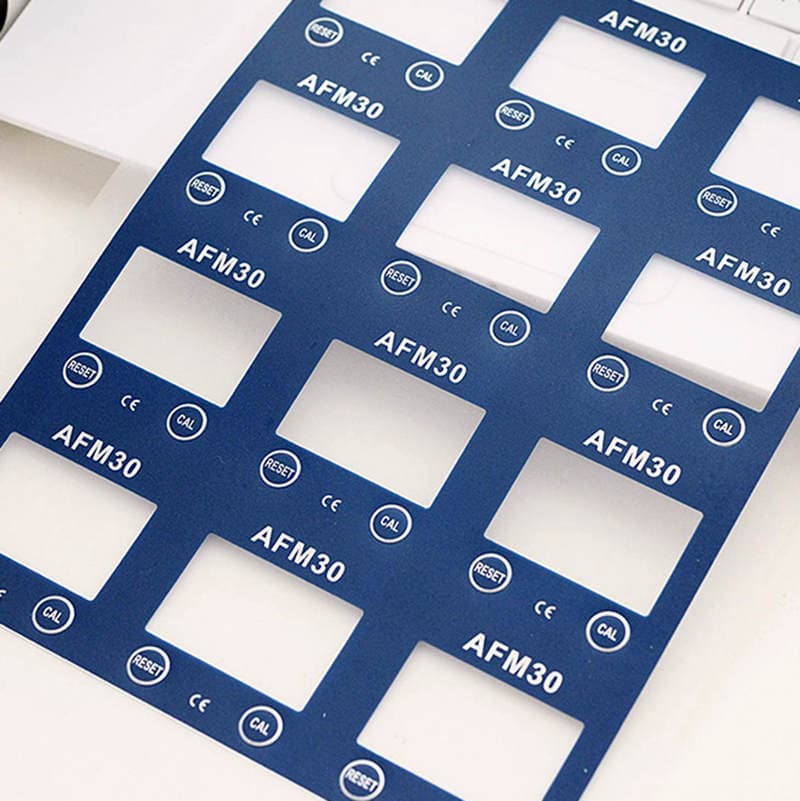

Polycarbonate Printing

UVPLASTIC offers excellent polycarbonate printing services including silkscreen printing and ink printing.

Polycarbonate Gluing

Different applications will have different requirements for glue when you use polycarbonate as the main material for your projects. UVPLASTIC will choose the suitable glue according to the application, size, environment. Meantime, we will test it under the cruelest conditions and make sure the polycarbonate part will meed and exceed your expectations.

Custom polycarbonate Fabrication

UVPLASTIC offers clients with custom polycarbonate machining service, OEM service for your polycarbonate parts need. Just give us your idea, we will submit the integrated polycarbonate fabrication solution.

We also have our own polycarbonate products, such as