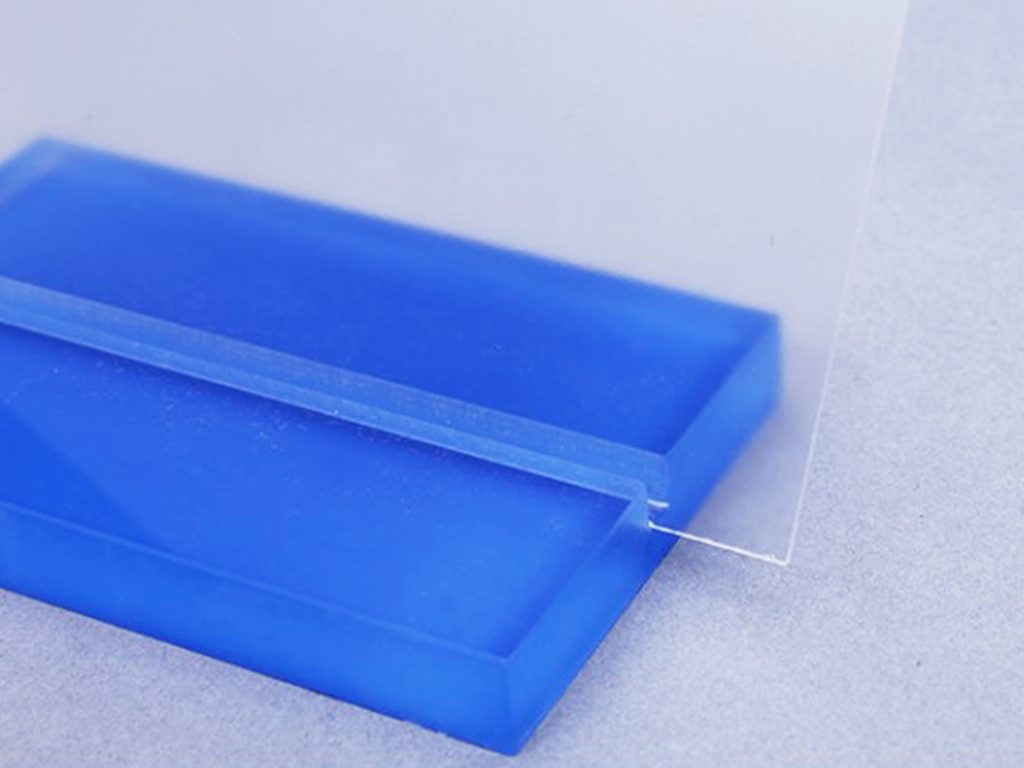

Scratch Resistant Acrylic Sheet

Product Description

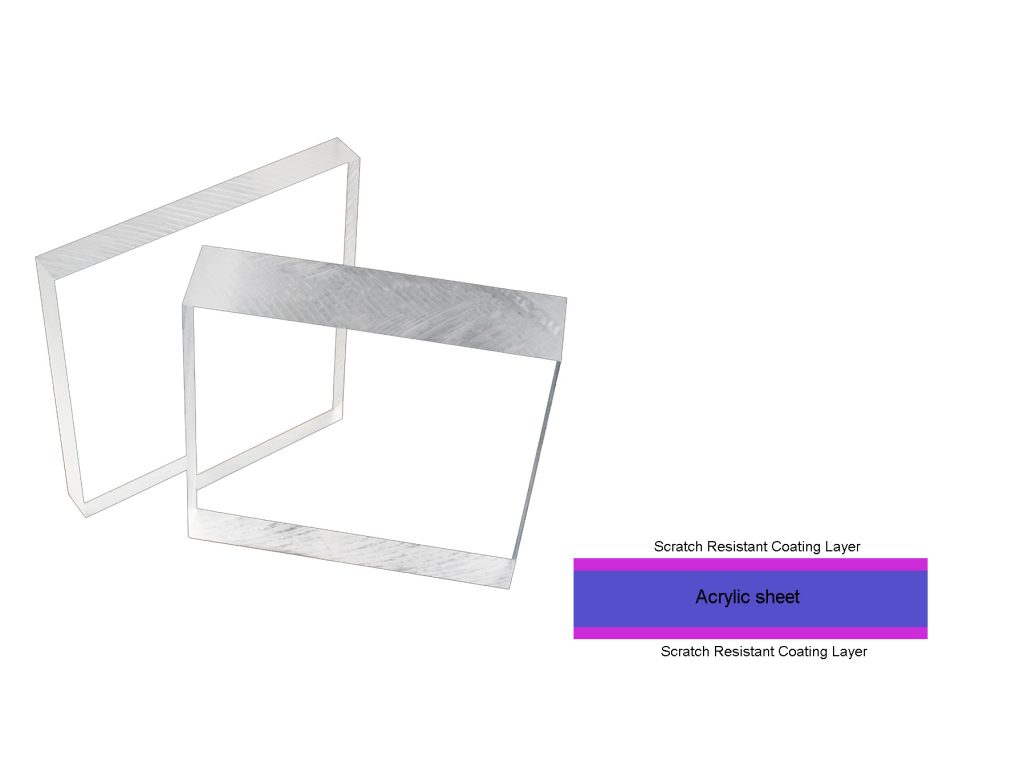

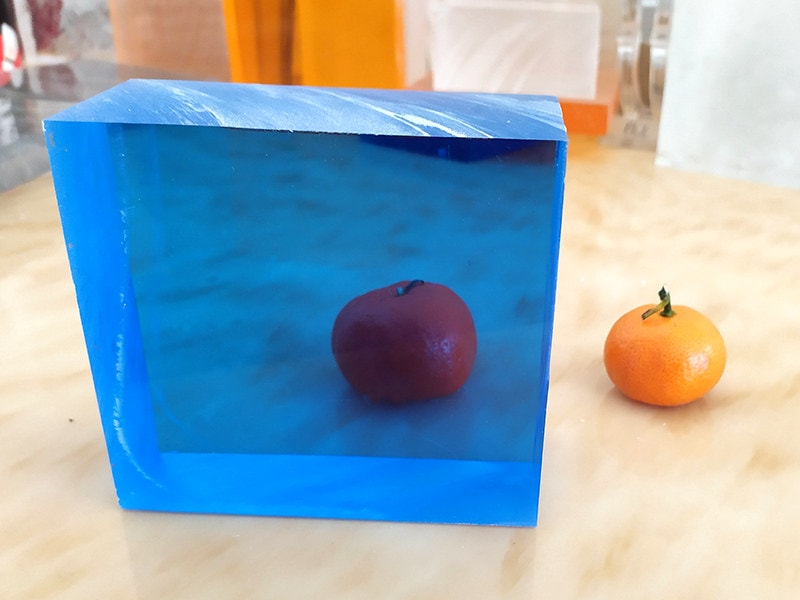

Scratch resistant acrylic offers more than 40 times greater resistance to scratch and chemical than standard acrylic sheet as the scratch-resistant coating layers on one or two sides. Meantime, the scratch-resistant coating layers don’t affect the outstanding optical property. Someone calls “Scratch resistant plexiglass”, “Abrasion resistant acrylic”, “Scratch resistant plastic” or “anti scratch acrylic sheet“.

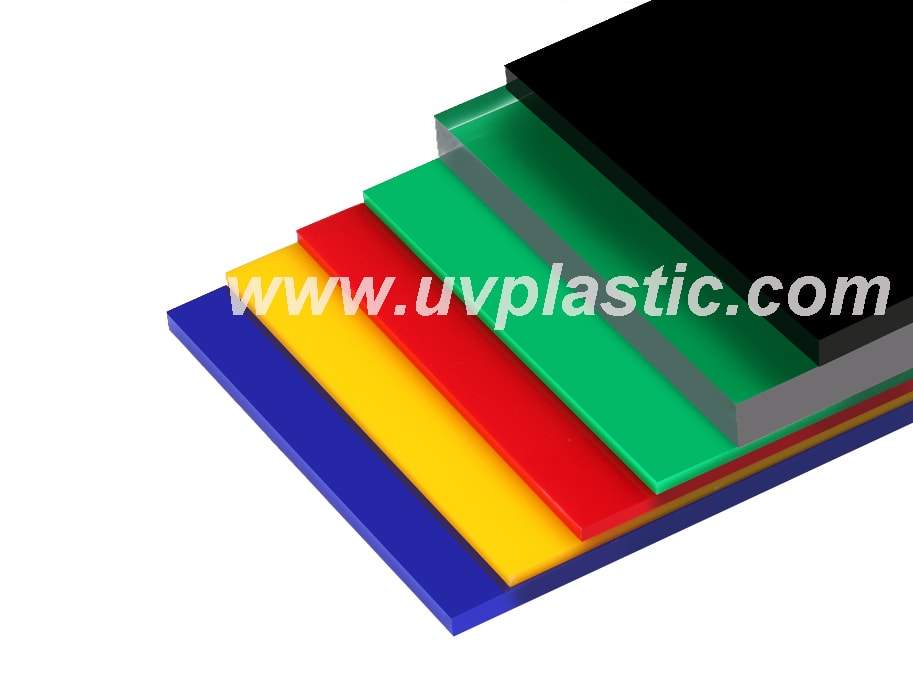

It is an ideal material to replace glass for artwork display, acrylic jewelry display box, flat-panel monitors, etc.

Product Specification

Product Range

| Model | Description |

|---|---|

| UVAC-SR | The abrasion-resistant coating on two sides |

| Product Name | Thickness (mm) | Standard Sizes (mm) | Standard Size (ft) |

|---|---|---|---|

| Scratch resistant acrylic sheet | From 2 mm to 20 mm | 1220 x 2440 | 4×8 |

Note:

- UVPLASTIC can cut to size upon the requirement of clients;

Physical Property

| Properties | Unit | Value |

|---|---|---|

| Density | g/cm^3 | 1.19 |

| Light transmittance | % | >90 |

| Haze | % | <1 |

| Pencil hardness | 3H or 4H | |

| Tensile Strength | Mpa | >70 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | KJ/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittance | % | >90 |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

Note:

- The properties shown by the above table are typical values intended for reference and comparison purposes only.

- They are NOT used for design specifications.