Best Polycarbonate Facade System & Building Curtain Walls

Leading Supplier of polycarbonate facade System and building curtain walls

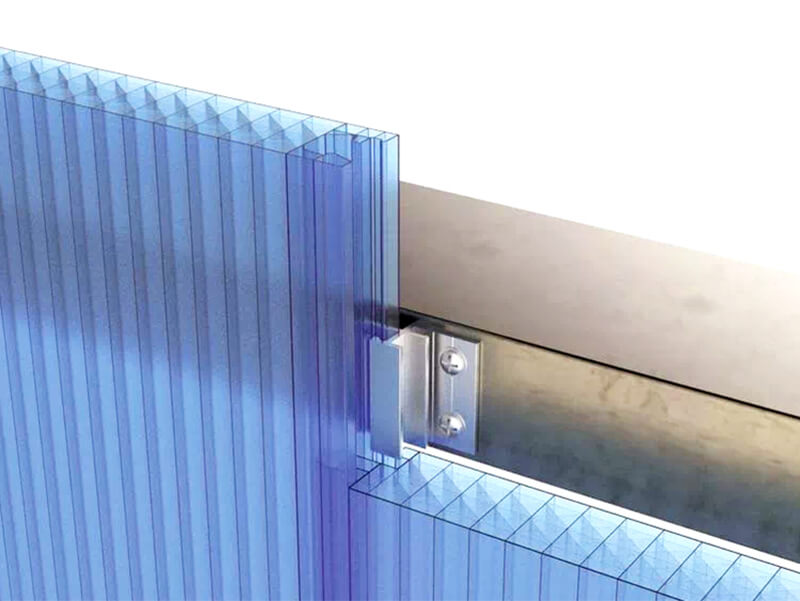

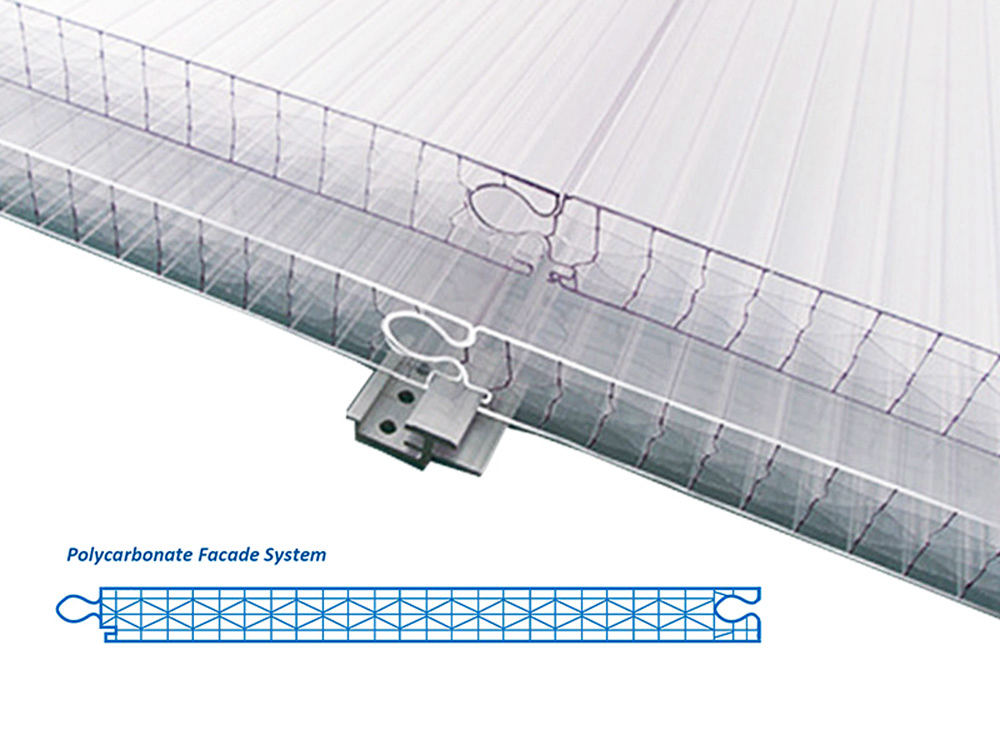

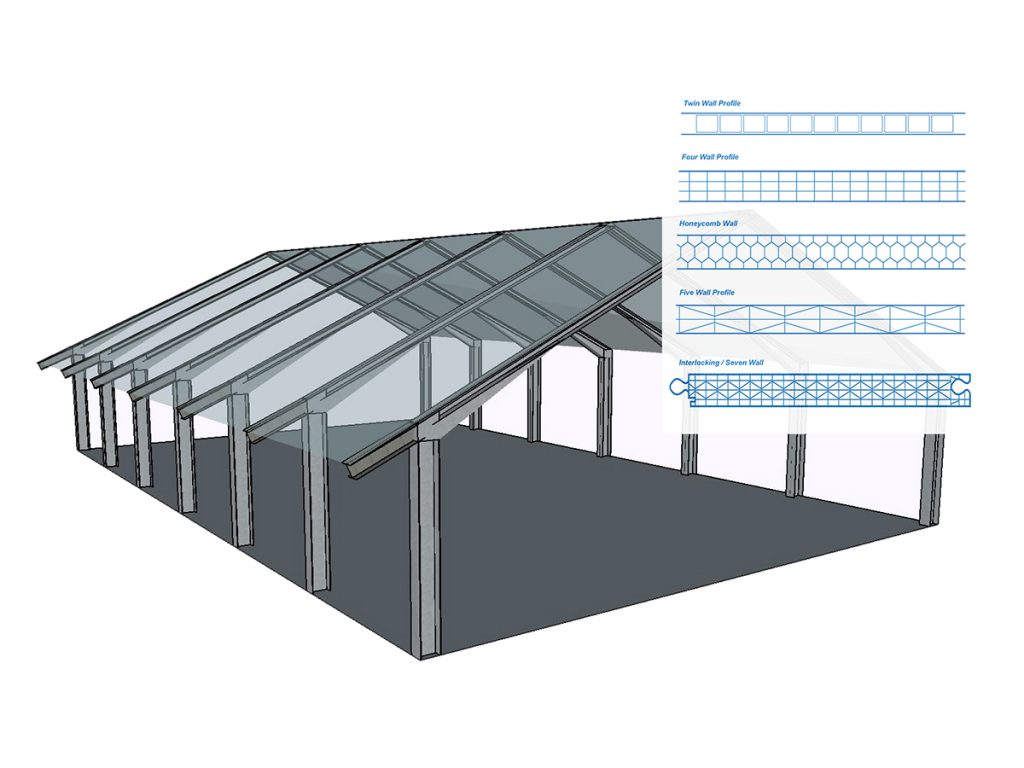

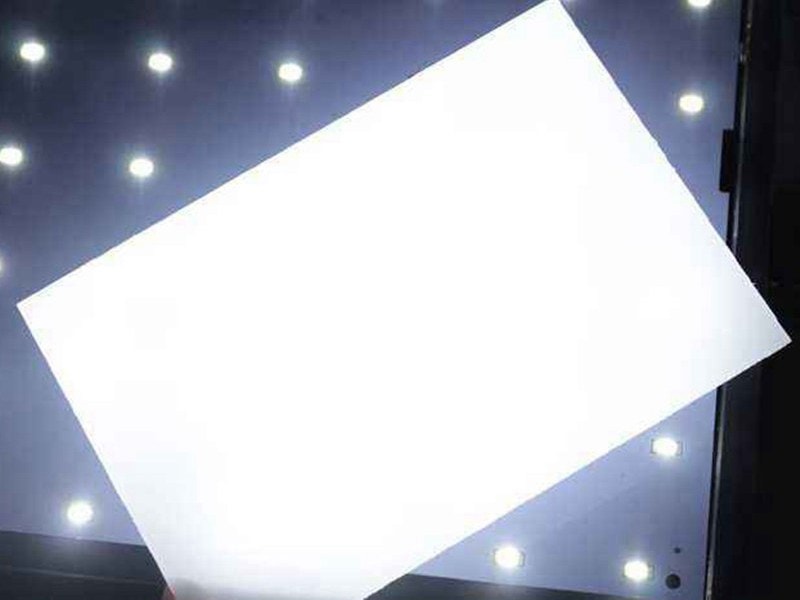

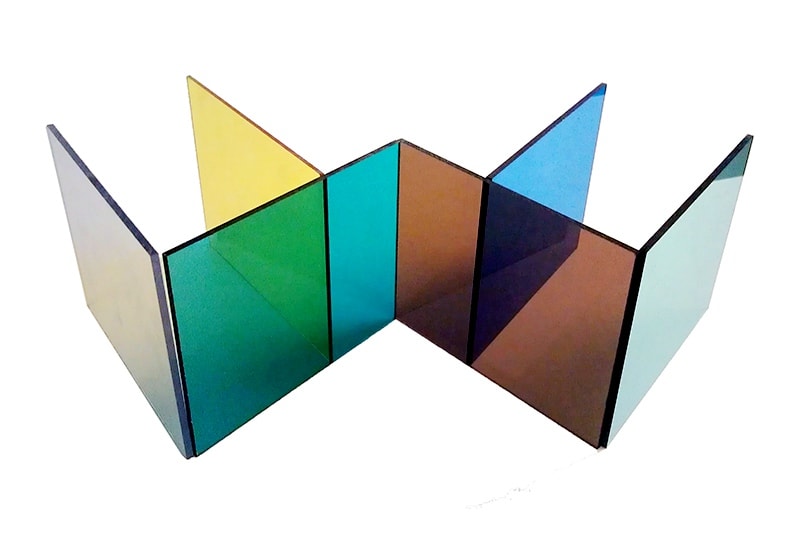

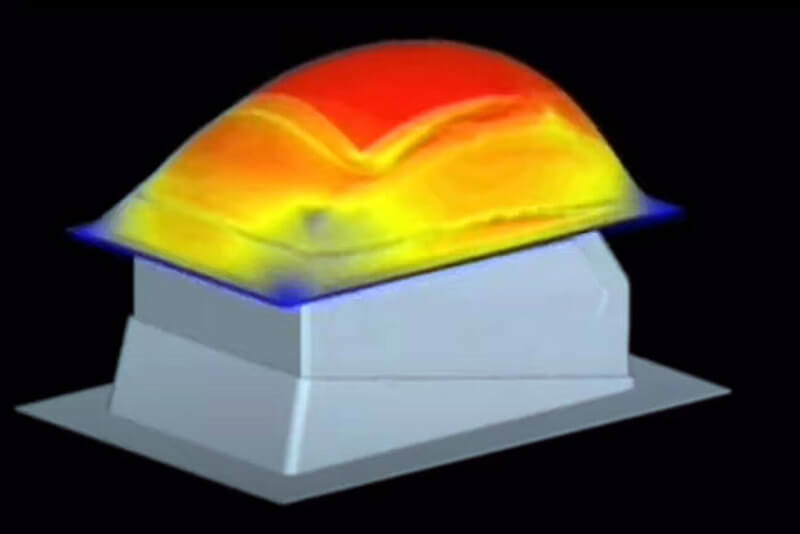

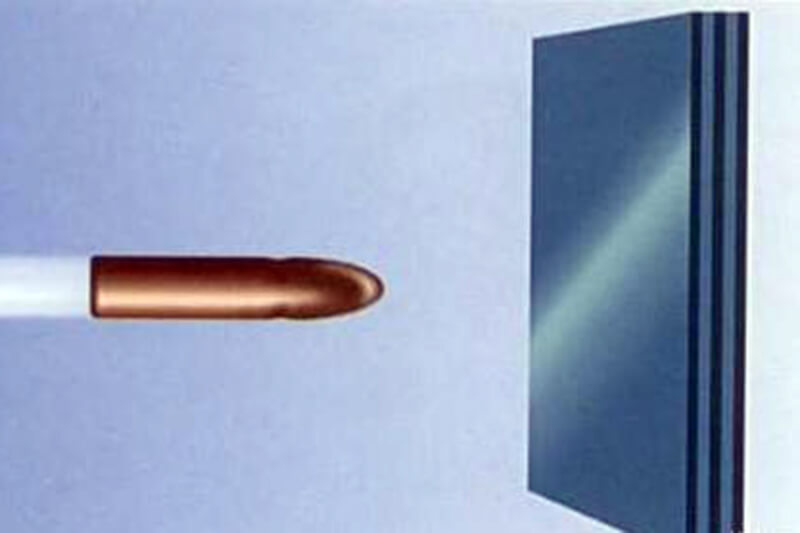

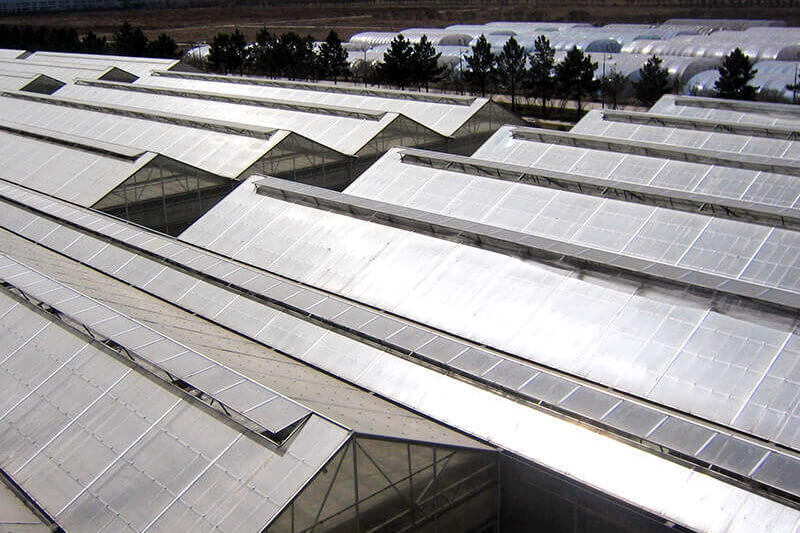

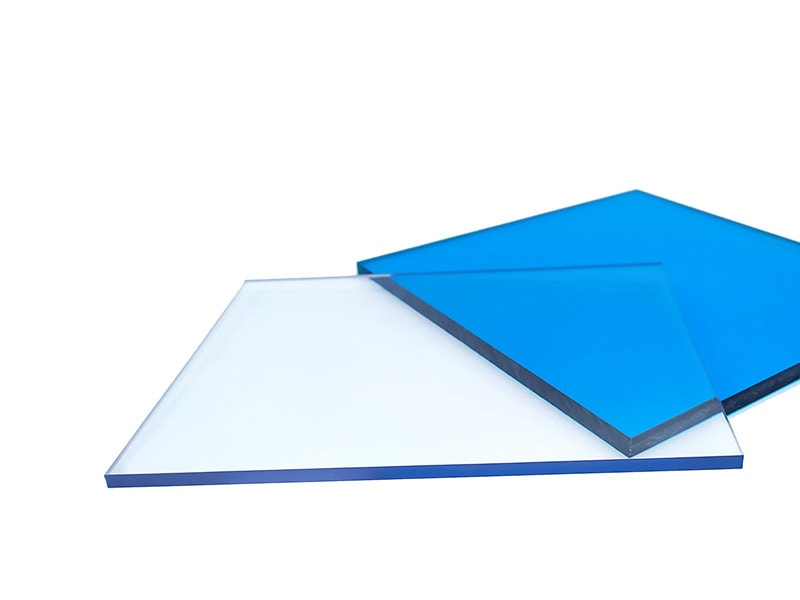

Polycarbonate Facade System is one of the most popular solutions for building curtain walls, it offers eye-catching visual effects, fantastic functionality, and Great durability. Polycarbonate facade sheet is much stronger than glass and offers excellent impact resistance, sound insulation, thermal insulation while letting in daylight, therefore, the polycarbonate facade system can help to save the air condition, heating, and light cost. It also creates an amazing effect when working with LED Light at night.

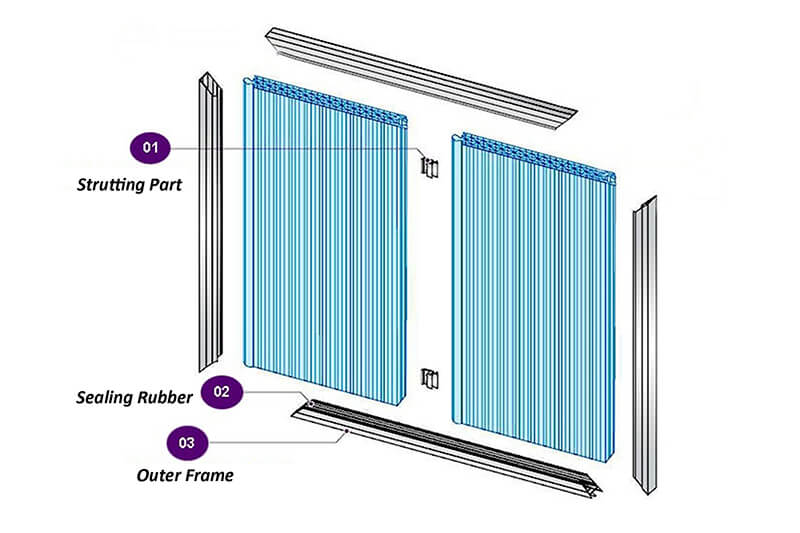

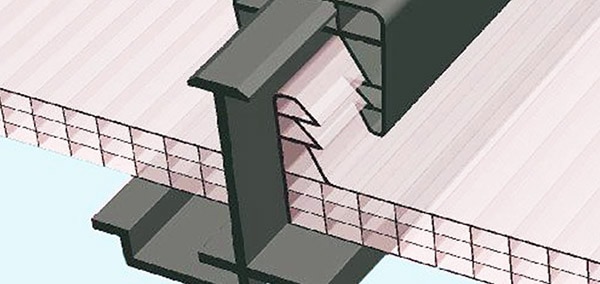

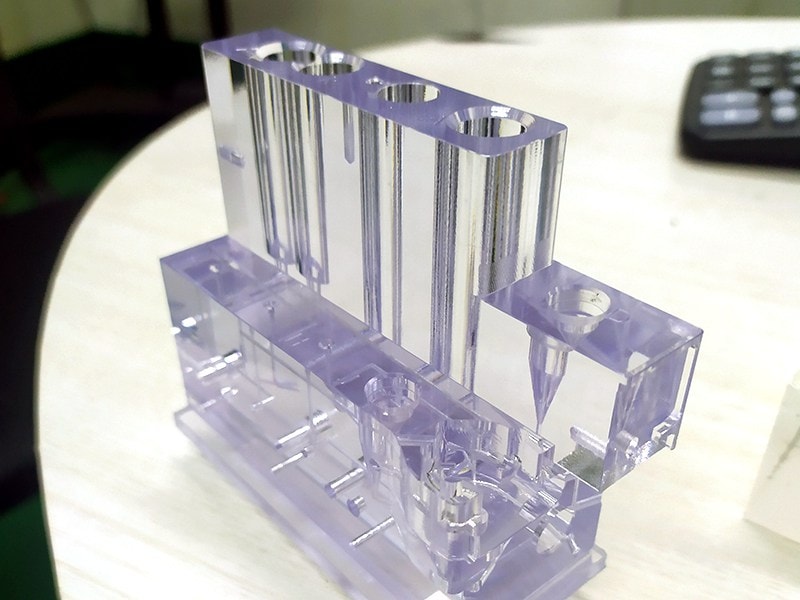

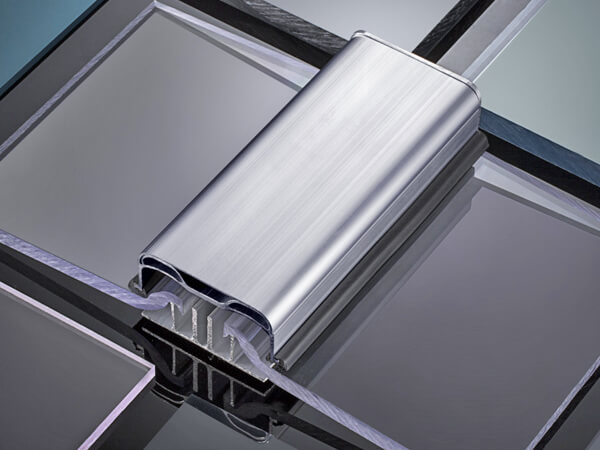

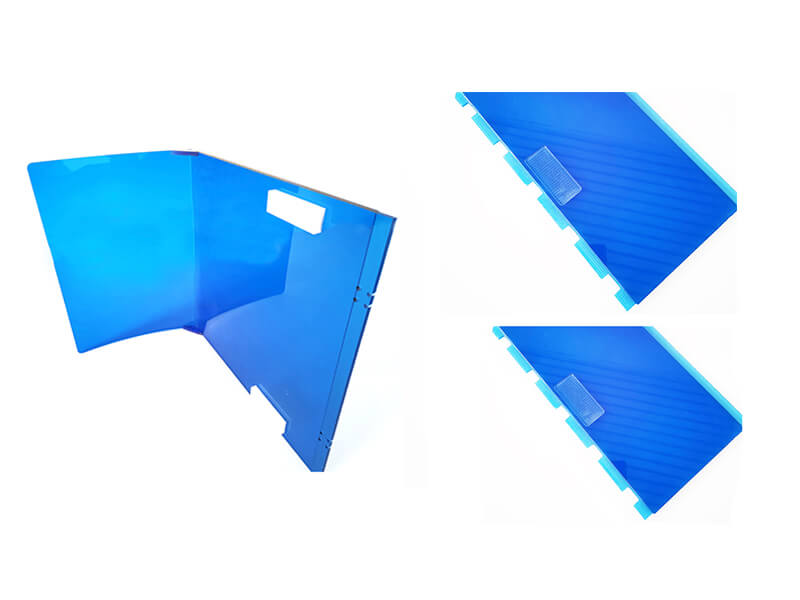

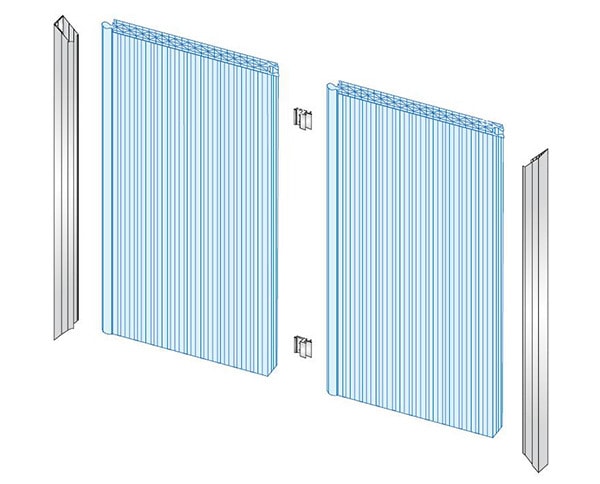

UVFA is the product code of the Polycarbonate Facade System, including Plug Pattern Polycarbonate Panel with water drain channel, Aluminum Fitting Parts, and Aluminum Frames. Plug Pattern Polycarbonate Panel offers flexible length, standard thickness & width. It offers various surfaces, such as bright surfaces, solar control, light diffusion, matt surface, etc.

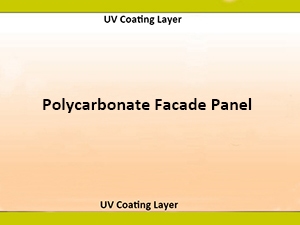

With the UV coating layers on one or two sides, UVFA Polycarbonate Facade System has excellent durability for about 15 years. It is the best material for the hangar, building curtain walls, indoor partition, etc.

Specification of Polycarbonate Facade System

Technical Parameters of UVFA Polycarbonate Facade System

| No. | Item | Description | Remark |

|---|---|---|---|

| 1 | Product Name | Polycarbonate Facade System or Curtain Walls | Including Plug Pattern Polycarbonate Panel, Strutting Part, and Outer Frames |

| 2 | Model | UVFA | |

| 3 | Thickness | 30mm, 40mm, 50mm | |

| 4 | Standard Width | 500mm | |

| 5 | Weight | 3.5 kg/sqm, 4.5 kg/sqm, 5.3 kg/sqm | |

| 6 | Length | Can be customized | |

| 7 | Light Transmittance (Clear) | 55% | |

| 8 | U Value | 1.1 W/sqm*K | |

| 9 | Linear Thermal Expansion | 10^-5 /degree | |

| 10 | Working Temperature | From -50 to 120 degree | |

| 11 | Tensile Strength | 62 Mpa | |

| 12 | Elongation at break | >80% |

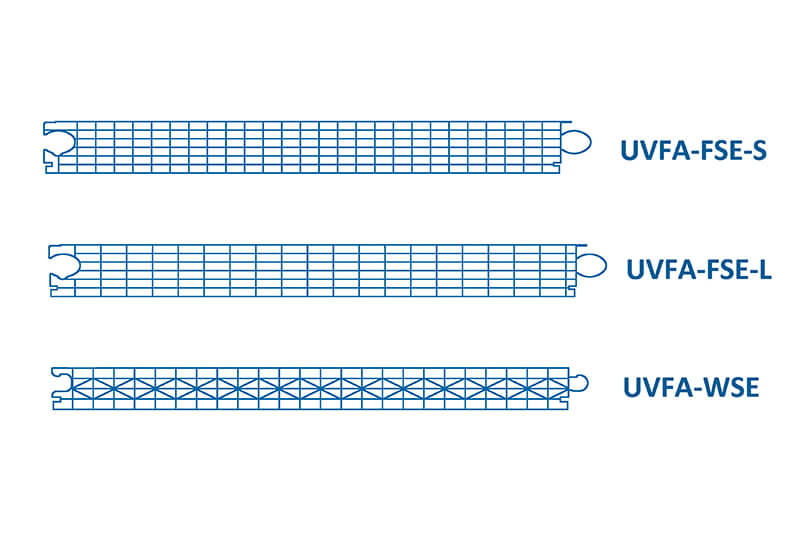

Model

| Model | Description |

|---|---|

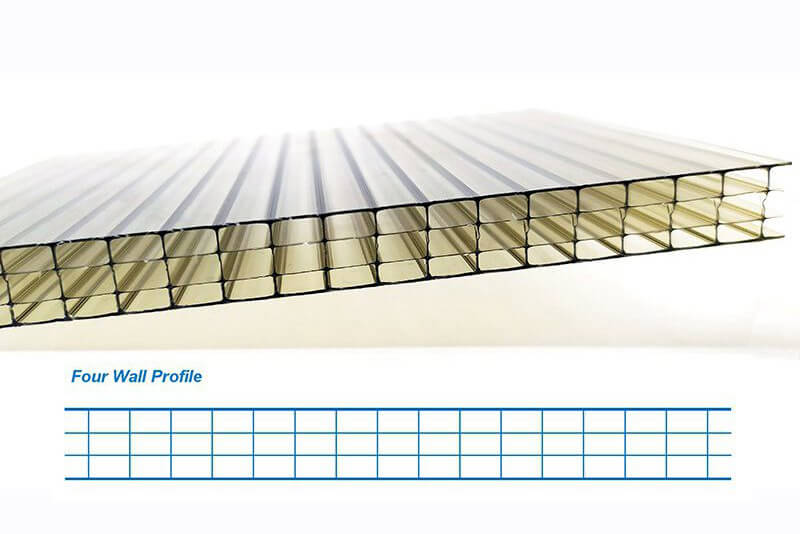

| UVFA-FSE-S | Seven-Layer connective ribs with small space, 40mm and 50mm in thickness; |

| UVFA-FSE-L | Seven-Layer connective ribs with longer space, 40mm and 50mm in thickness; |

| UVFA-WSE | Seven-Layer connective ribs with W-type space, 30mm and 40mm in thickness; |

Co-extruded Layer Range

| Model | Description |

|---|---|

| UVFA-U1 | Standard Polycarbonate Facade Panel With Co-extruded UV Layer On One Side |

| UVFA-SO | Solar Control Polycarbonate Facade |

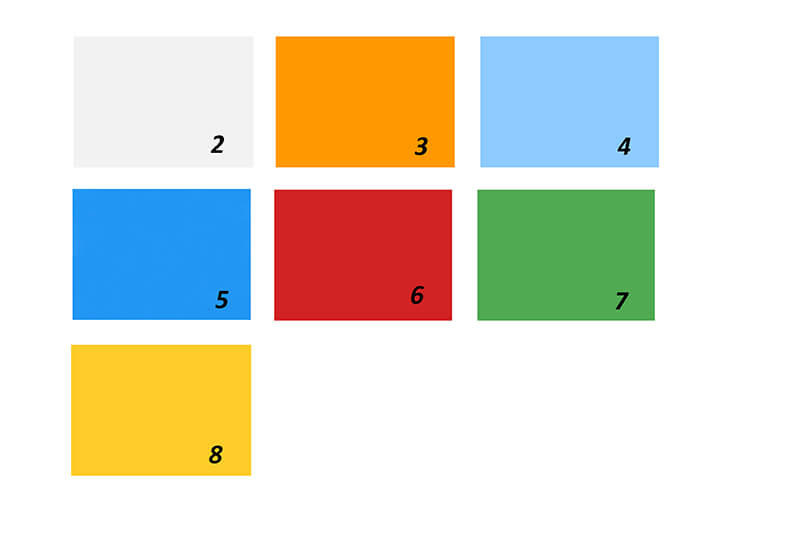

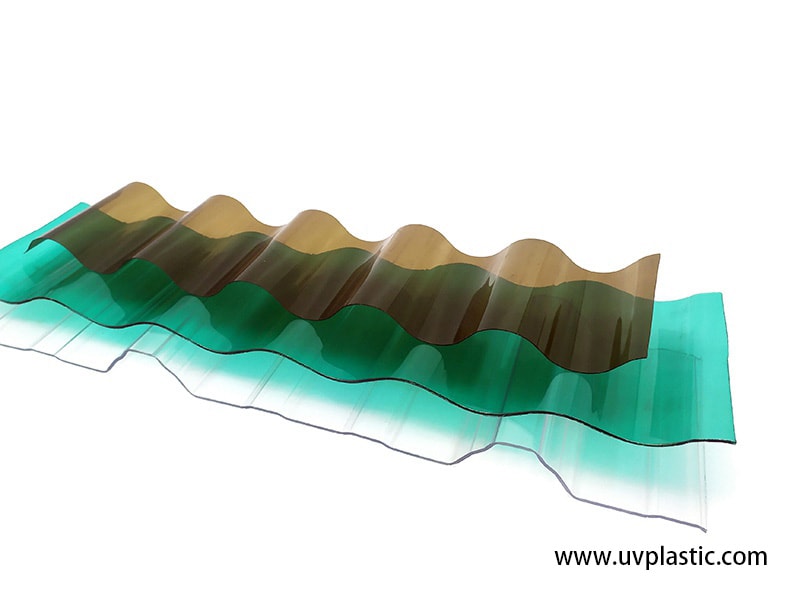

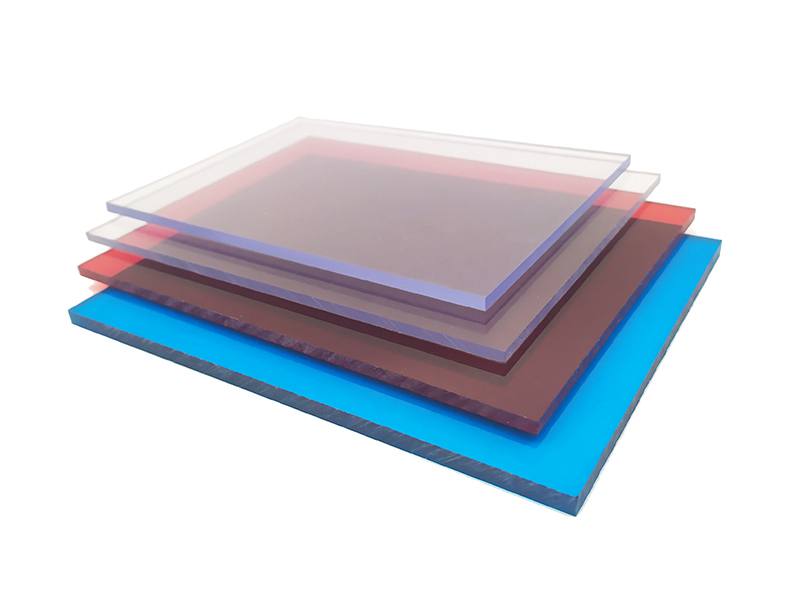

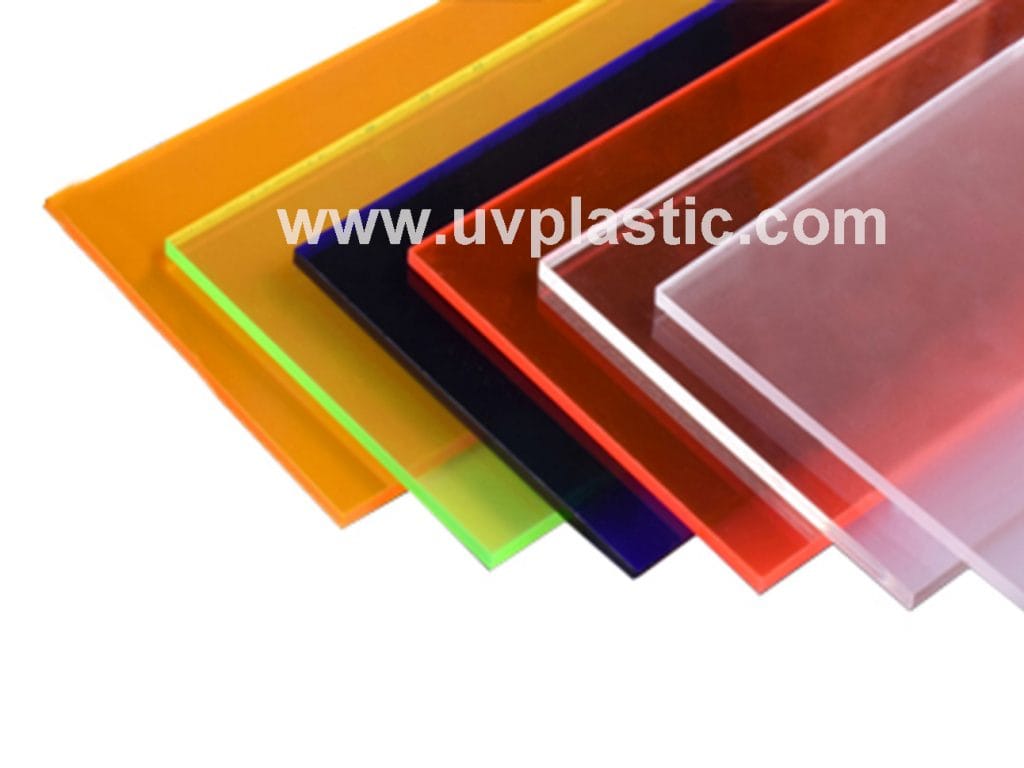

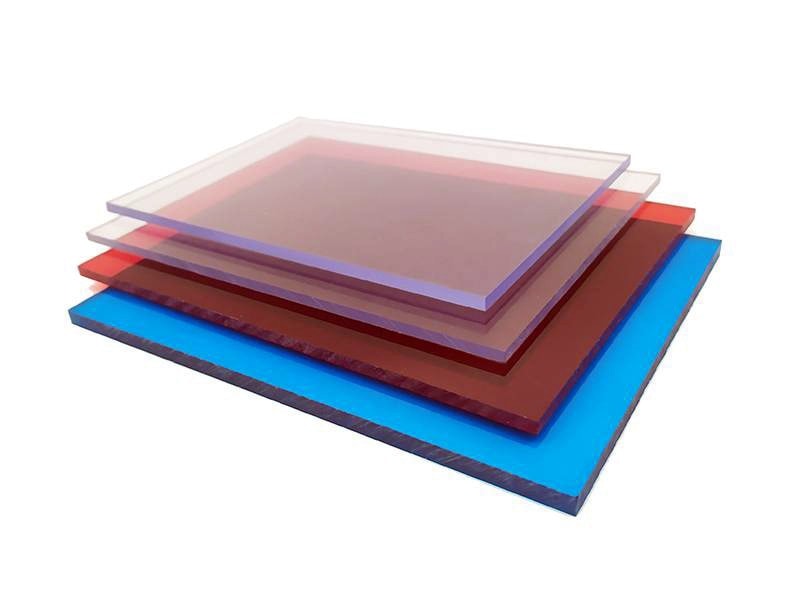

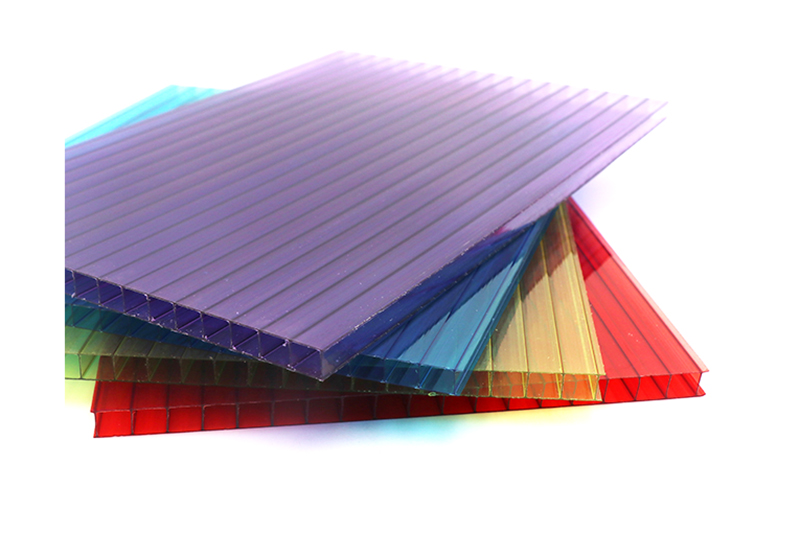

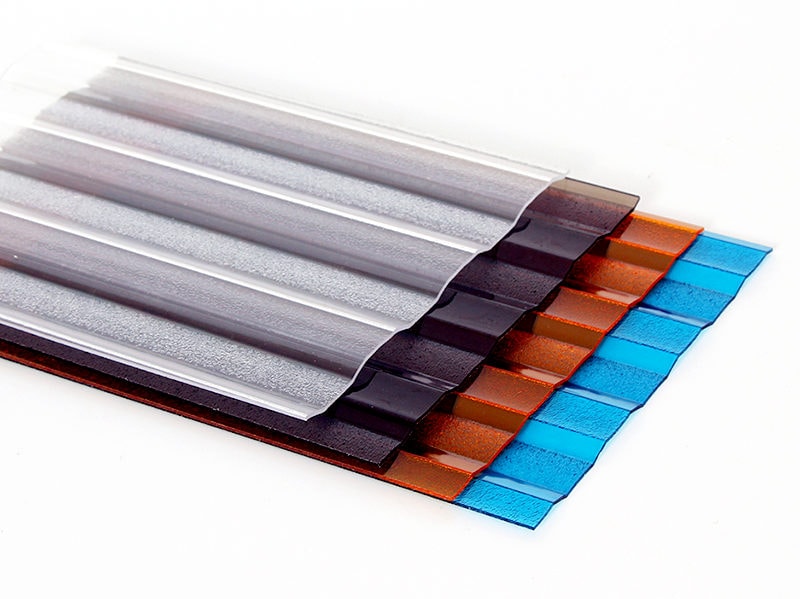

Colors Range for uVFA Polycarbonate Facade System

| Model | Description |

|---|---|

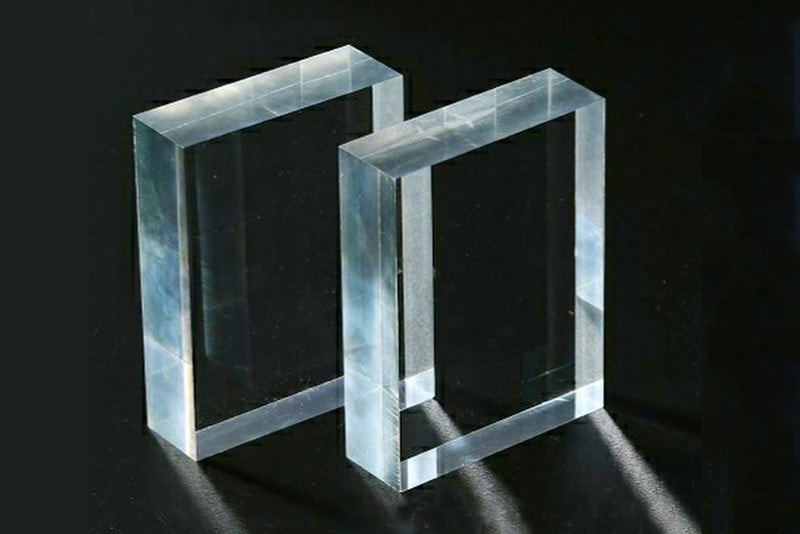

| UVFA-0 | Transparent |

| UVFA-1 | Transparent with bright effect |

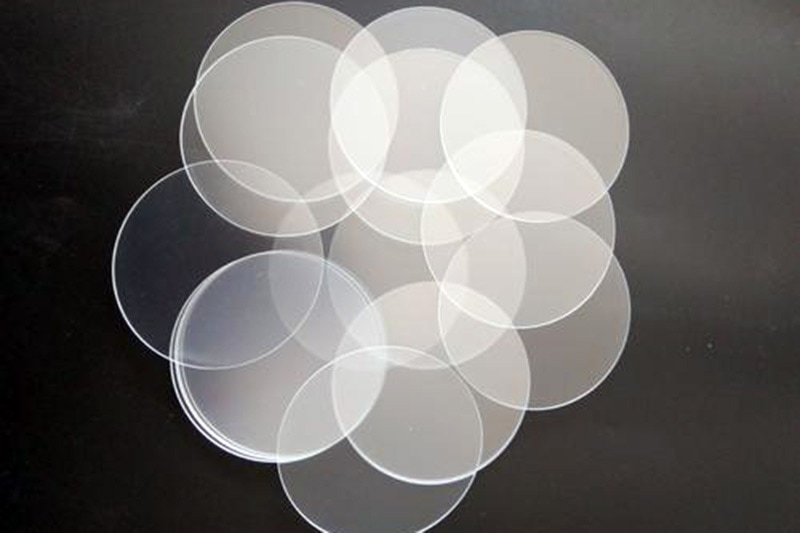

| UVFA-2 | Milky white with diffuser |

| UVFA-3 | Orange |

| UVFA-4 | Pale blue or sky blue |

| UVFA-5 | Brilliant blue |

| UVFA-6 | Red |

| UVFA-7 | Green |

| UVFA-8 | Yellow |

Accessories

UL Flammability Standard Released By Underwriters Laboratories

UVFA Polycarbonate Facade meets the V-0/UL94 and ClassA/B of ASTM E84

Restriction Of Hazardous Substances

UVPLASTIC offers environmentally-friendly polycarbonate sheets and meets RoHS and REACH

Download Catalog

Main Benefits

For a Fast Quotation, You Need to Tell Us Following Information

Application

We need to know your application and the detailed project for the integrated solution of the facade system proposal.

Length

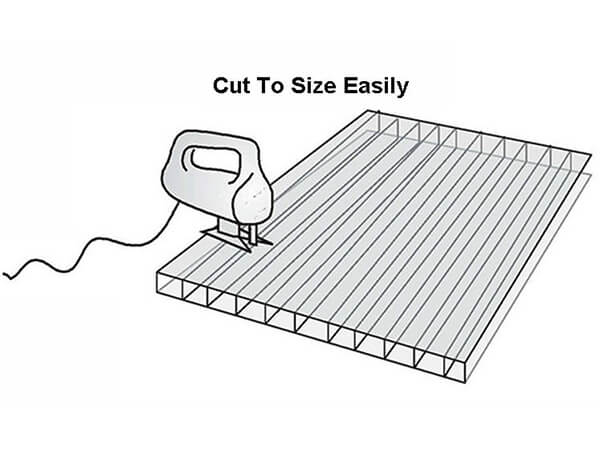

UVFA Polycarbonate facade panel offers standard widths, the length is flexible, you need to tell us the length for an accurate quote.

Coating Requirement

The standard coating layer is one-side UV coating layer, but we provide a custom coating layer, such as UV coating on both layers, solar control coating layer.

Quantity

UVFA polycarbonate roofing sheet has MOQ requirement, you need to indicate the quantity, then we will submit the competitive offer.