Leading Manufacturer of Frosted Polycarbonate in China

Best Frosted Polycarbonate You Could Find In China

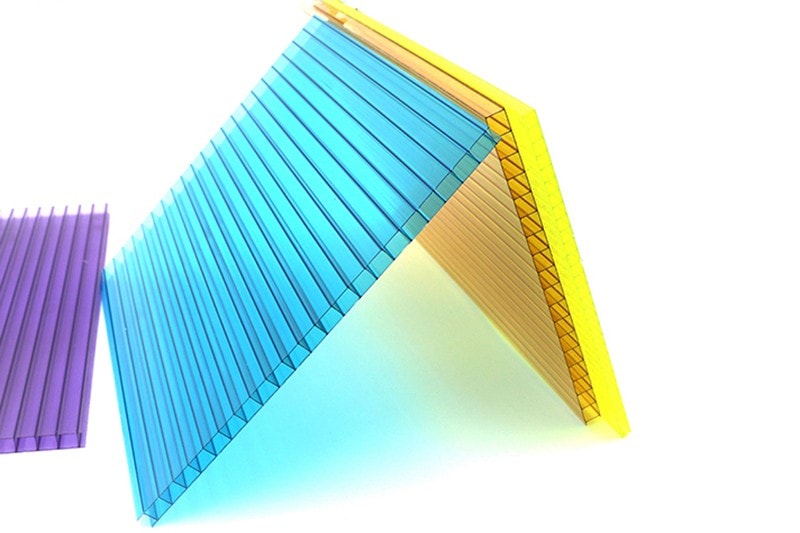

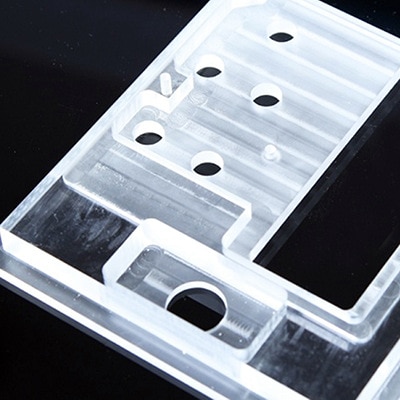

Frosted Polycarbonate sheet Introduction

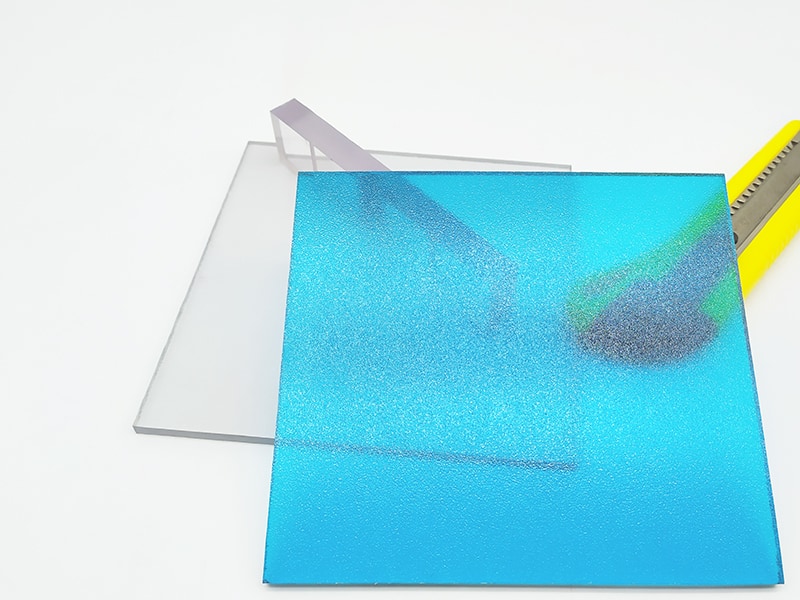

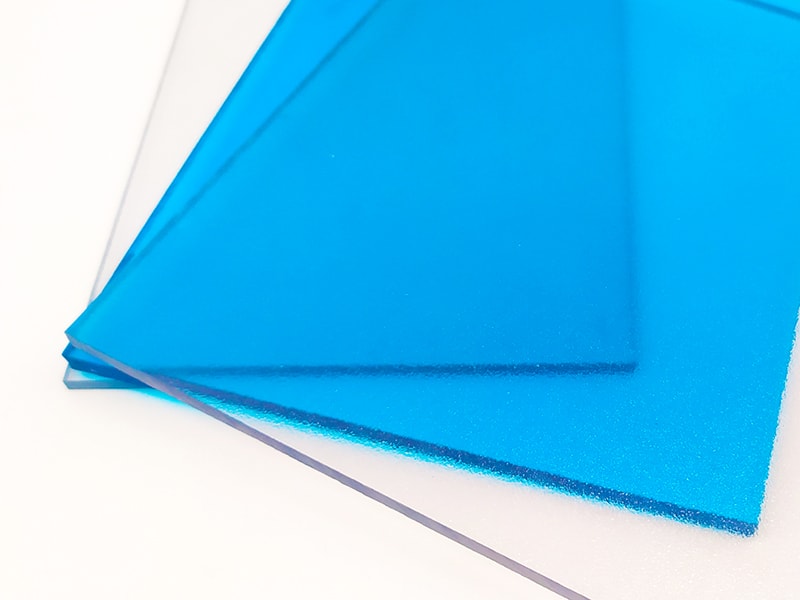

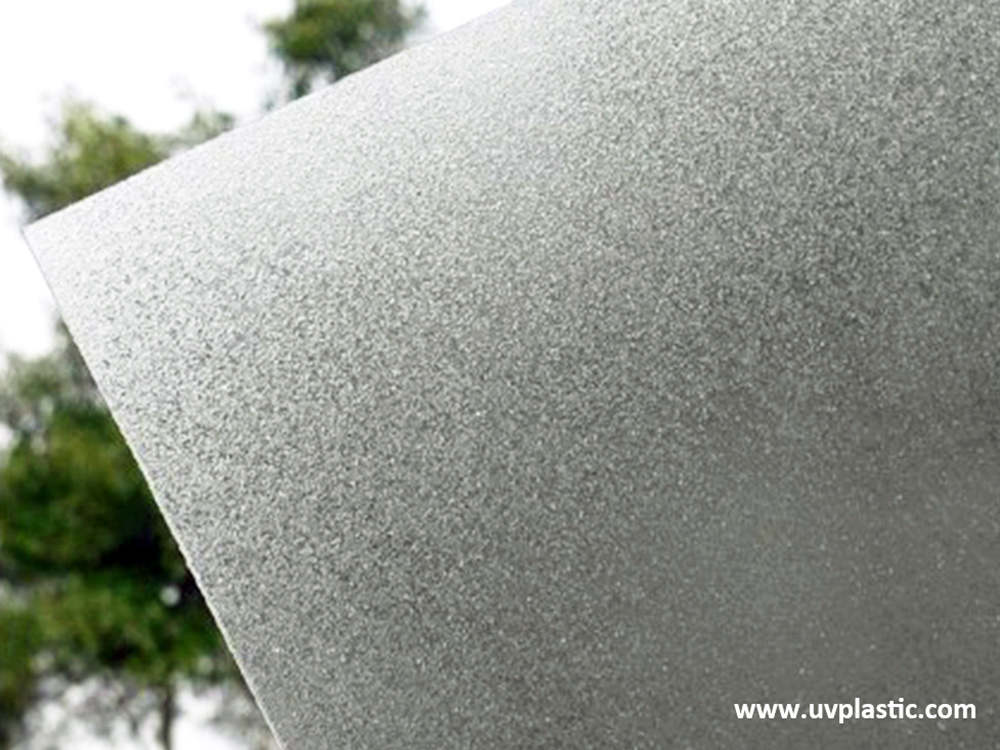

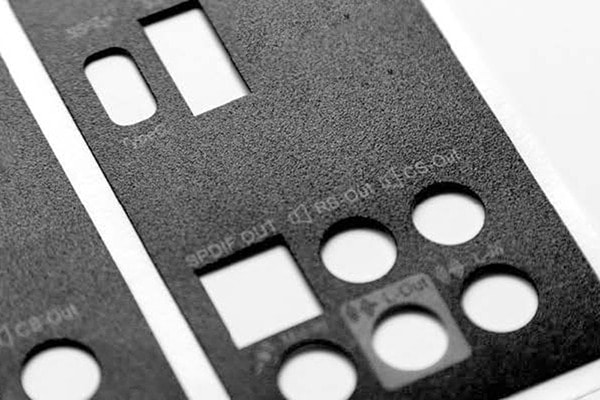

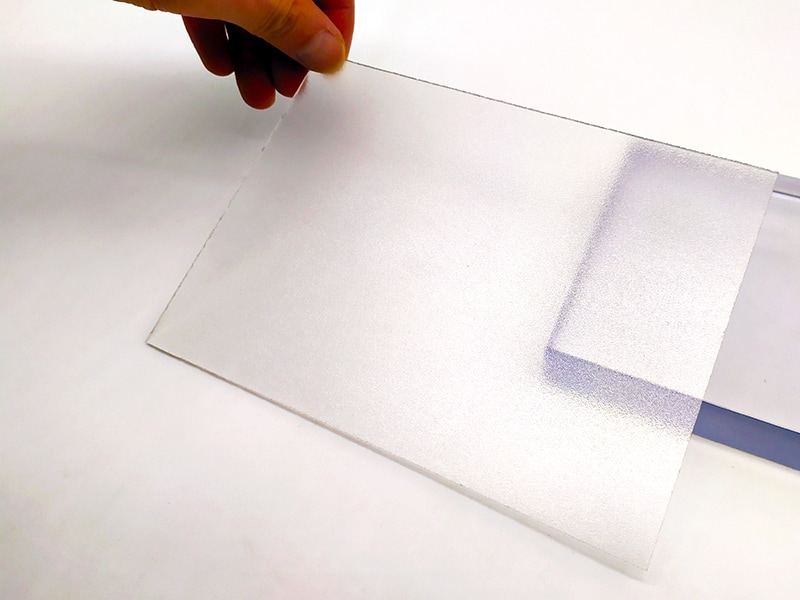

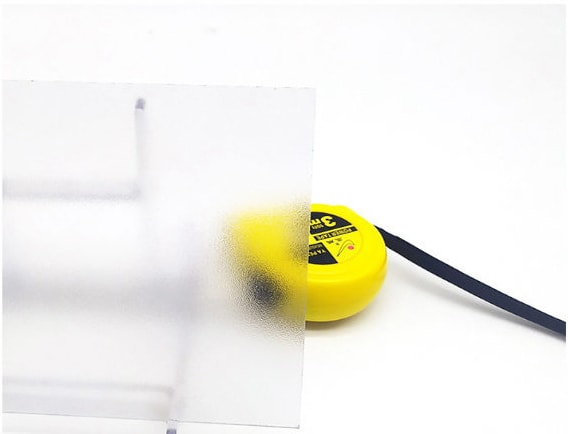

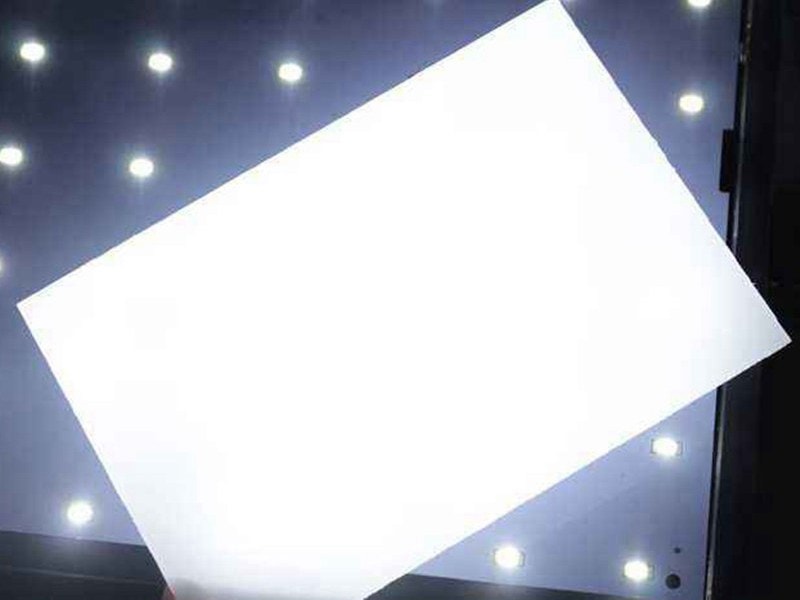

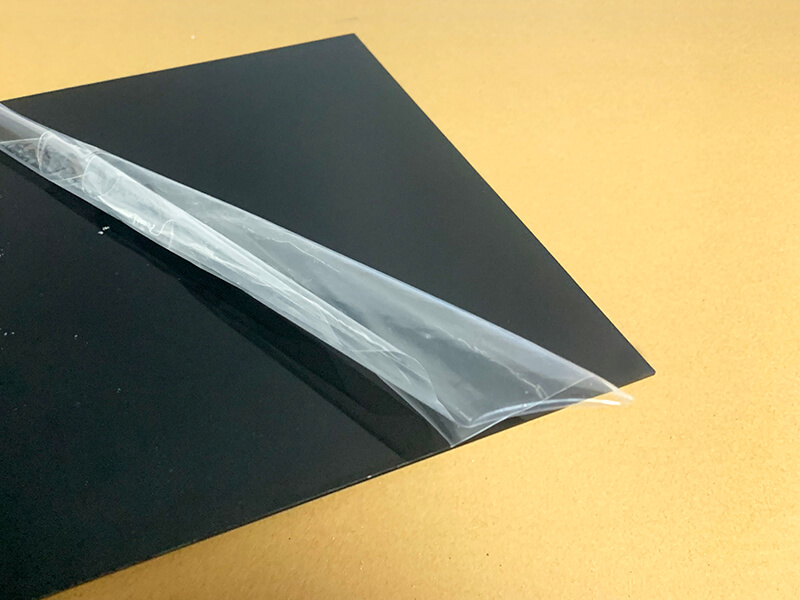

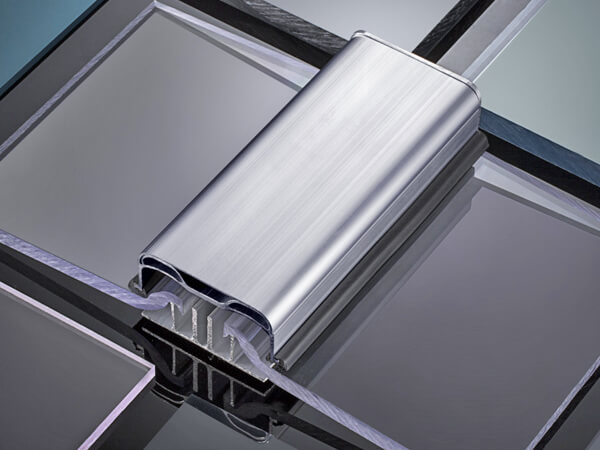

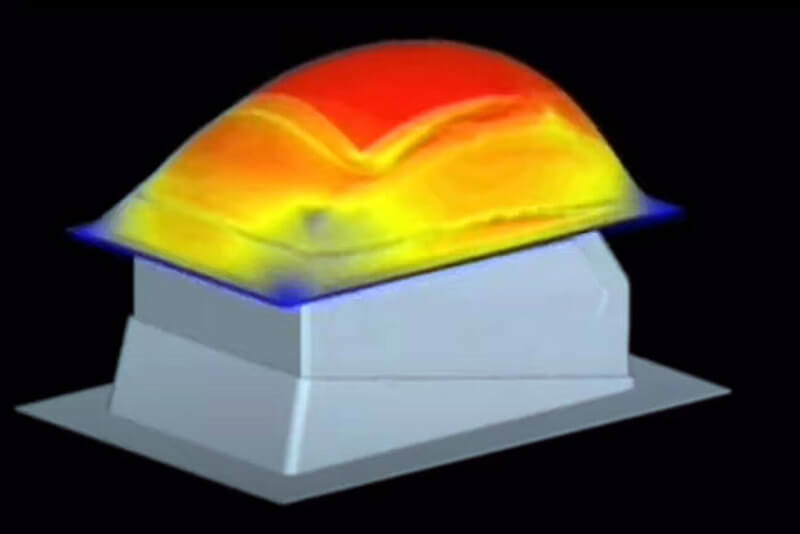

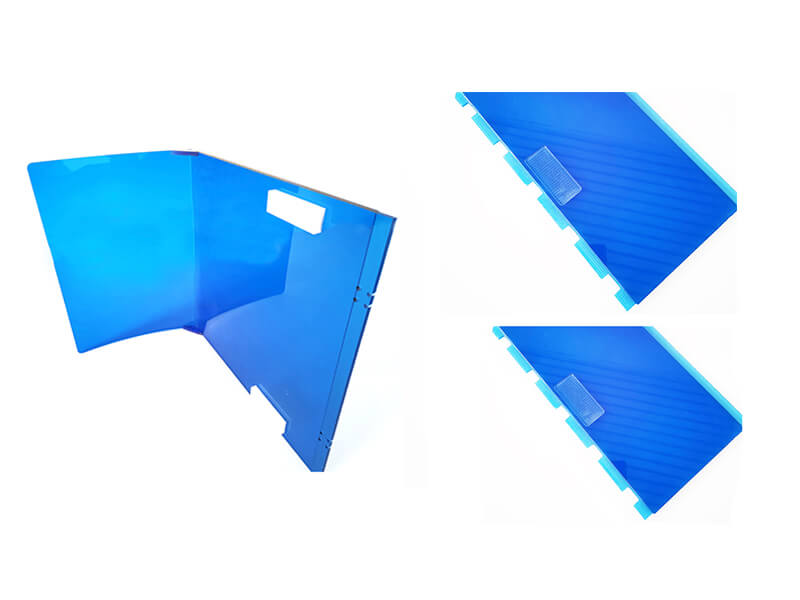

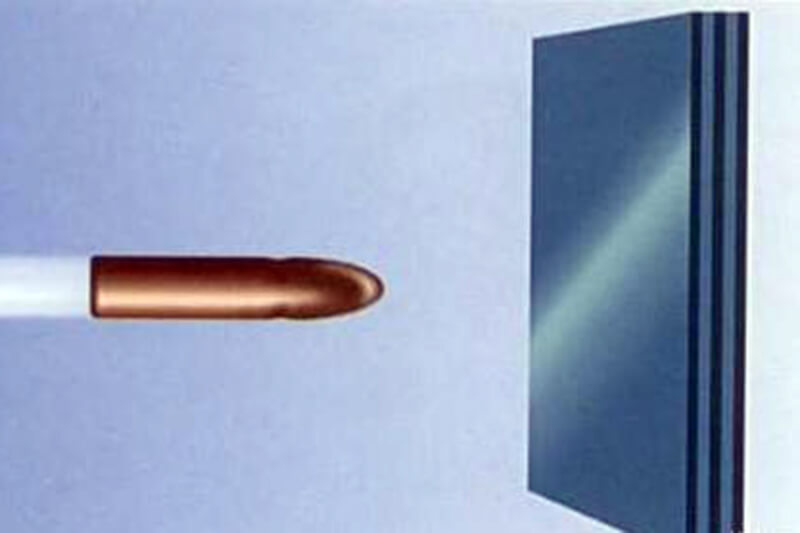

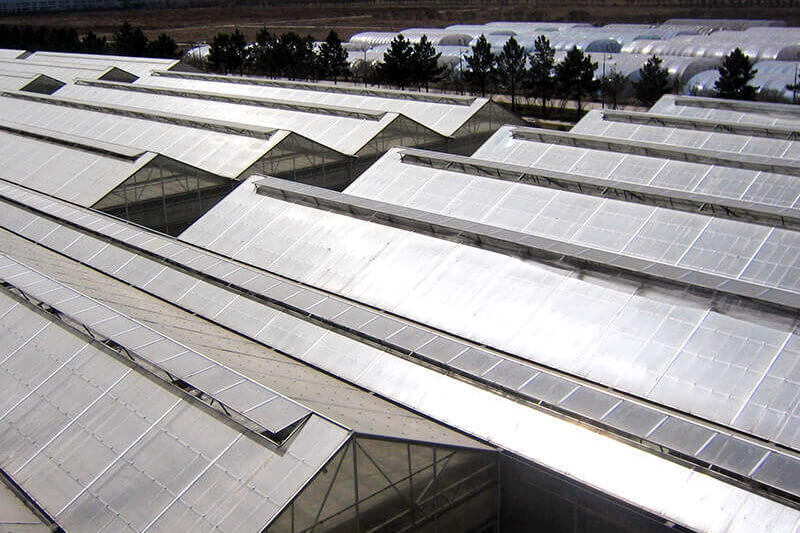

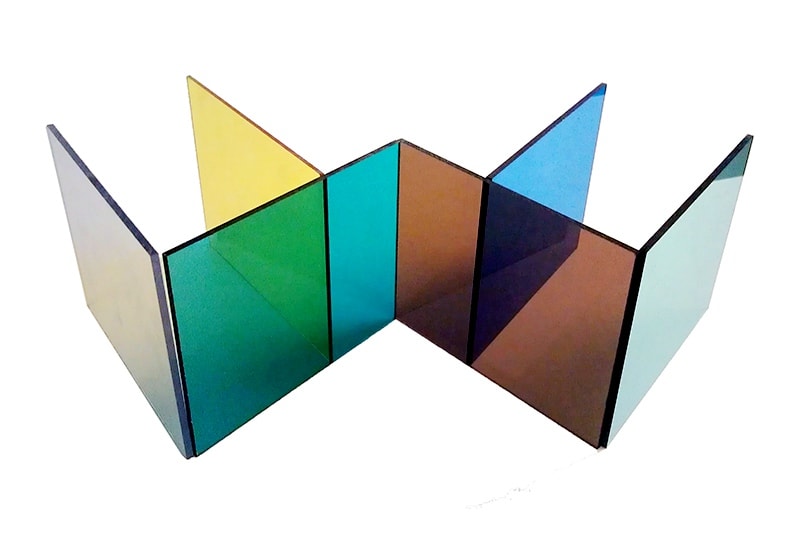

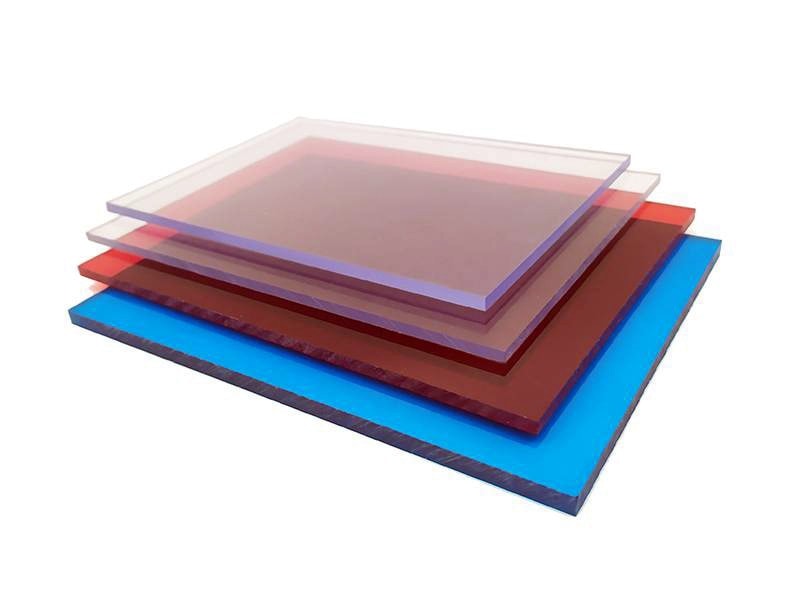

Frosted polycarbonate sheet is also called “Frosted Plastic Sheet” or “Matte Polycarbonate“, which is the right material mainly to add privacy and scratch resistance in office/home applications and printing products. It is also the best material for home decoration applications including printing products, shower enclosure, carport roof, office dividers between rooms, and skylight roof, because of the privacy matte patterns, which is to conceal something on the backface.

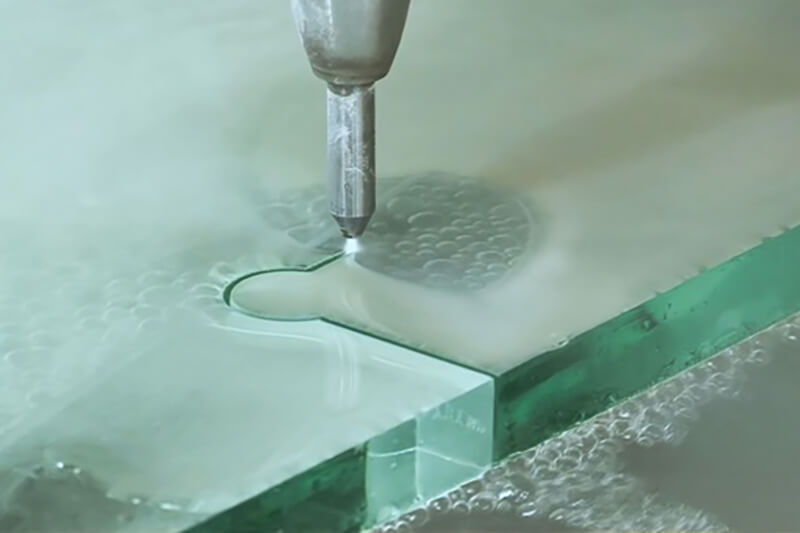

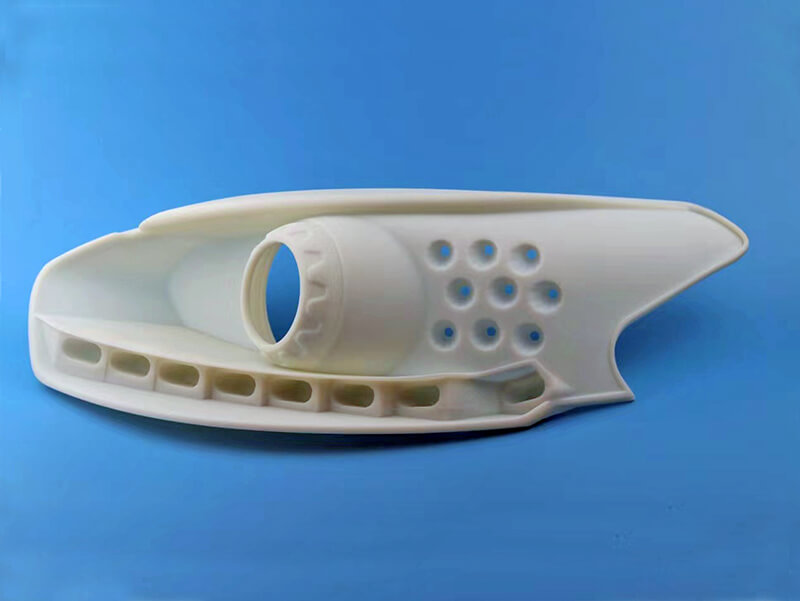

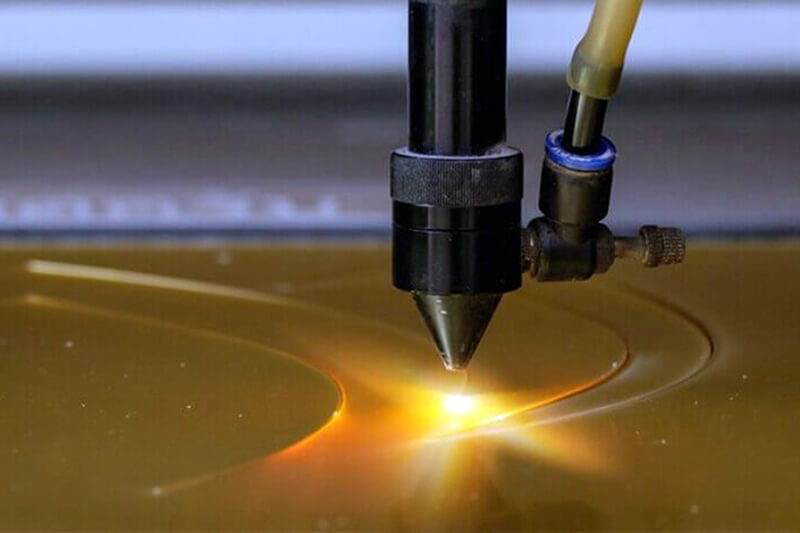

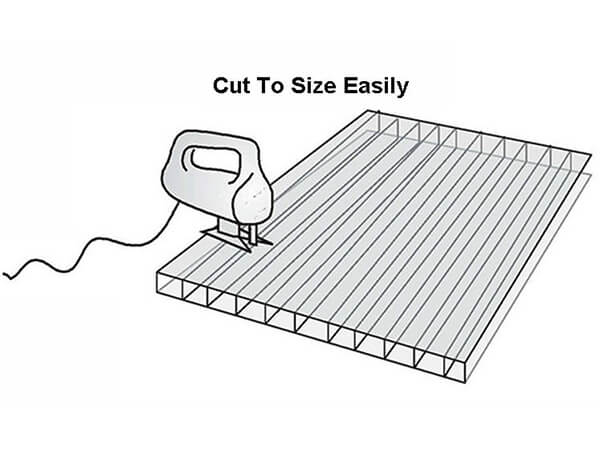

With more than 15 years of experience, UVPLASTIC has been the leading manufacturer of frosted polycarbonate sheets in China. Through cooperation with the different suppliers of raw materials, like Sabic, Covestro, Mitsubishi, and Teijin, we can provide high-quality frosted polycarbonate with thicknesses from 0.125mm to 15mm. It is widely used for home decoration, automotive trim, office, shopping mall, and picture frames. Otherwise, UVPLASTIC provides machining frosted polycarbonate service according to clients’ drawings.

Specification Of Frosted Polycarbonate Sheet

Standard Surfaces of Printable Frosted Polycarbonate

| Model | Textures | Thickness/mm | Width/mm |

|---|---|---|---|

| UVRPC-PP-122 | Matte/Velver | From 0.075 to 0.7mm | 930 or 1230mm |

| UVRPC-PP-121 | Matte/Fine Velver | From 0.075 to 0.7mm | 930 or 1230mm |

| UVRPC-PP-10 | Matte/Gloss | From 0.075 to 0.7mm | 930mm |

| UVRPC-PP-022 | Gloss/Velver | From 0.075 to 0.7mm | 930mm |

| UVRPC-PP-021 | Gloss/Fine Velver | From 0.075 to 0.7mm | 930mm |

Standard Size of Printable Frosted Polycarbonate

| Model | Thickness/mm | Width/mm | Length/m | Weight/Kg |

|---|---|---|---|---|

| UVRPC-PP-75 | 0.075 | 930 | 1066 | 89.3 |

| UVRPC-PP-125 | 0.125 | 930 | 640 | 89.3 |

| UVRPC-PP-175 | 0.175 | 930 | 457 | 89.3 |

| UVRPC-PP-250 | 0.25 | 930/1230 | 320 | 89.3/118 |

| UVRPC-PP-380 | 0.38 | 930 | 216 | 89.3 |

| UVRPC-PP-500 | 0.5 | 930/1230 | 166 | 197/260 |

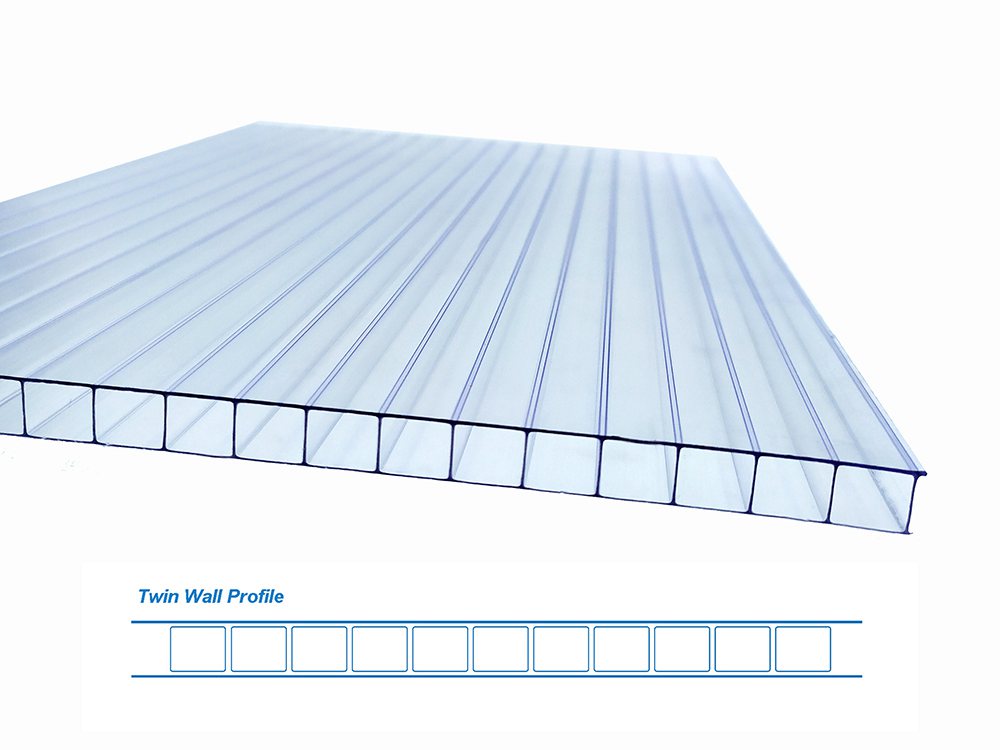

General-Use Frosted Polycarbonate Range

| Model | Surface | Description |

|---|---|---|

| UVFPC-FP | Frosted/Polished | No UV Coating Layer for indoor use |

| UVFPC-FP-UV1 | Frosted/Polished | Co-extruded UV Coating Layer on one side for outdoor use |

| UVFPC-FP-UV2 | Frosted/Polished | Co-extruded UV Coating Layer on both sides for outdoor use |

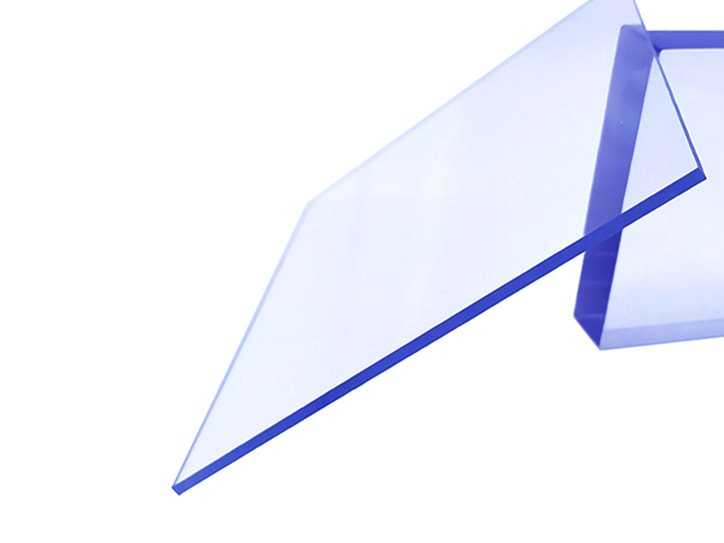

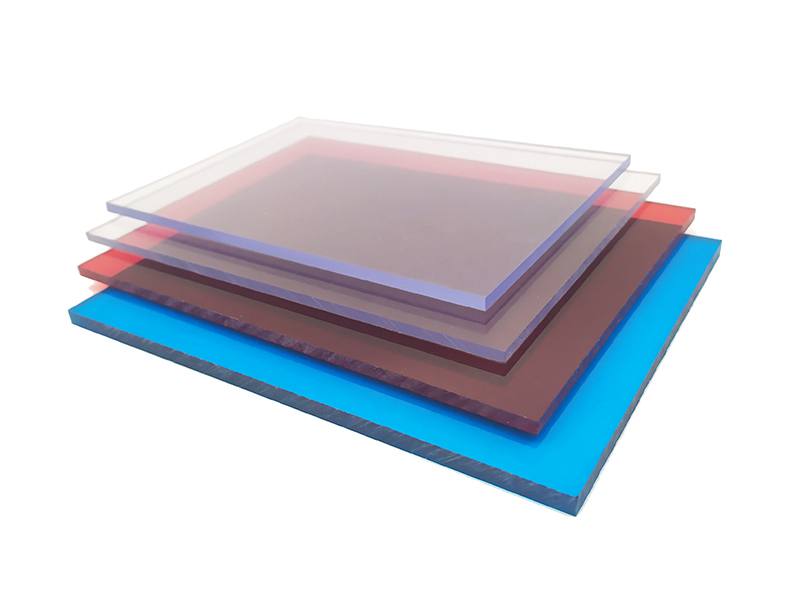

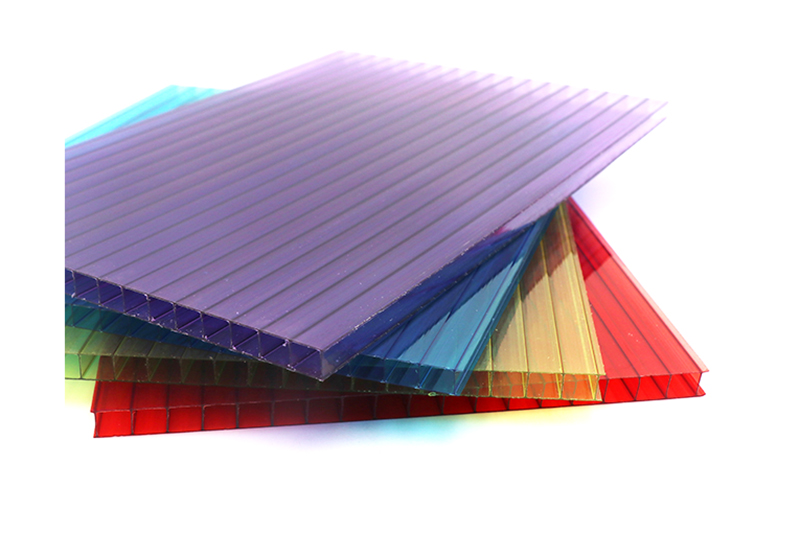

Colors Range: Clear, Blue, Green, White, Custom Color;

Standard Size of General-Use Frosted Polycarbonate

| Model | Thickness/mm | Width/mm | Length/mm |

|---|---|---|---|

| UVFPC-FP | 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10, 12, 14, 15, 20mm | 1000, 1220, 2100mm | 1220, 1830, 2000, 2440, 5800, 12800mm |

Physical Properties

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | D-792 | g/cm3 | 1.2 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Deflection Temperature (264 psi load) | ASTM D648 | °F/°C | 275/135 |

| Vicat Softening Point | ASTM D1525 | °F/°C | 284/140 |

| Maximum Continuous Service Temperature | — | °F/°C | 190/87 |

| Maximum Discontinuous Service Temperature | — | °F/°C | 210/98 |