Top Supplier of Polycarbonate Tubes in China

High-quality Polycarbonate Tube and Machining service

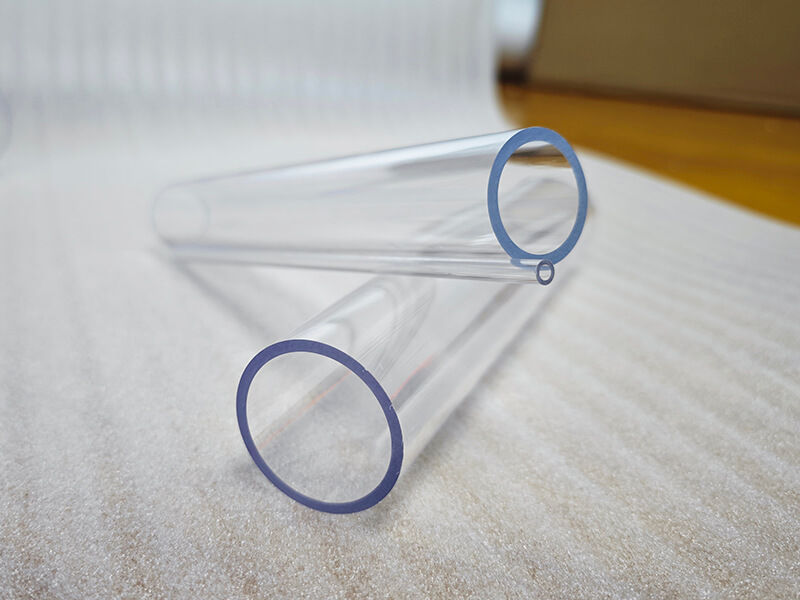

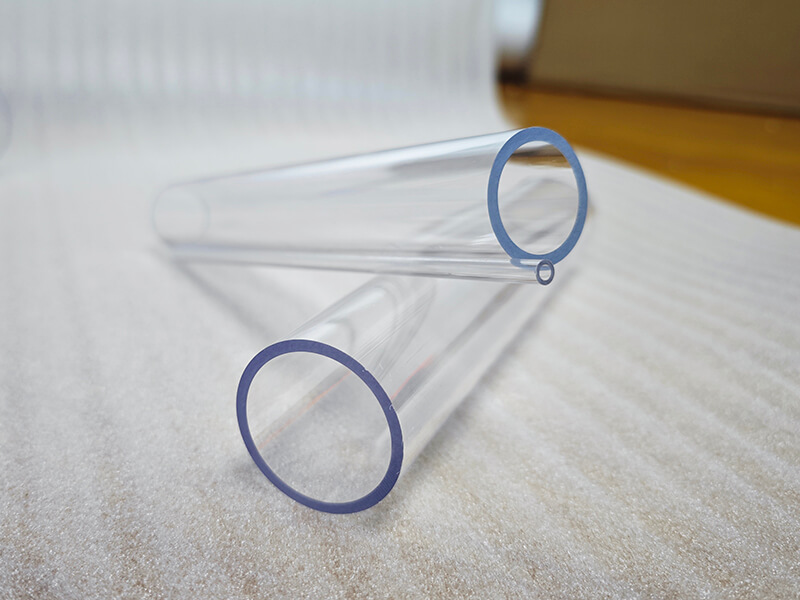

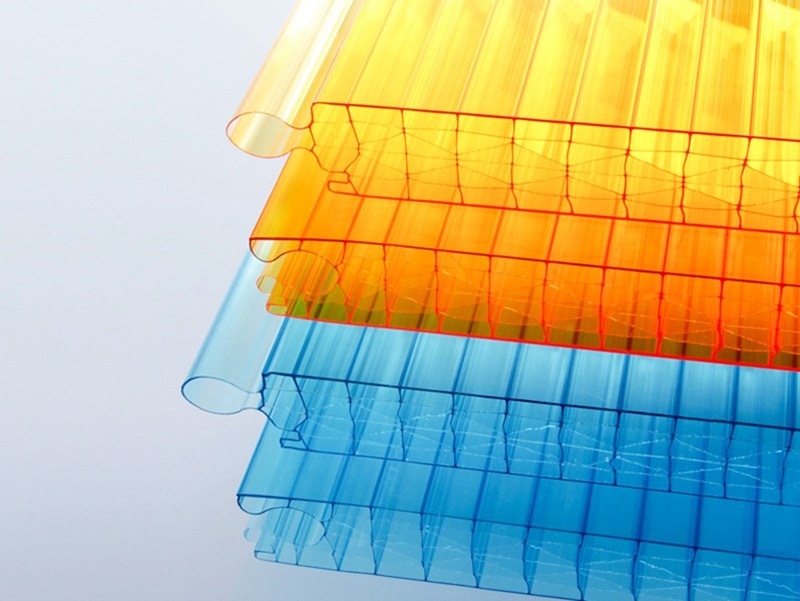

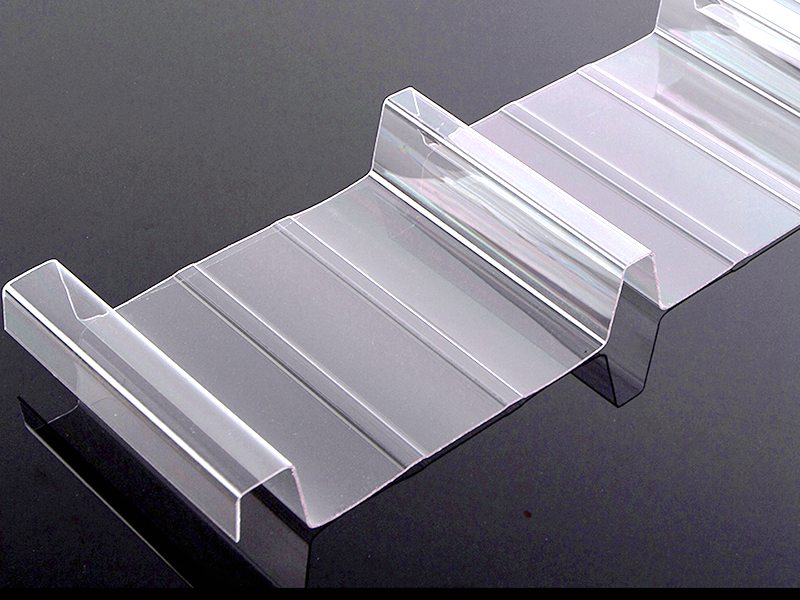

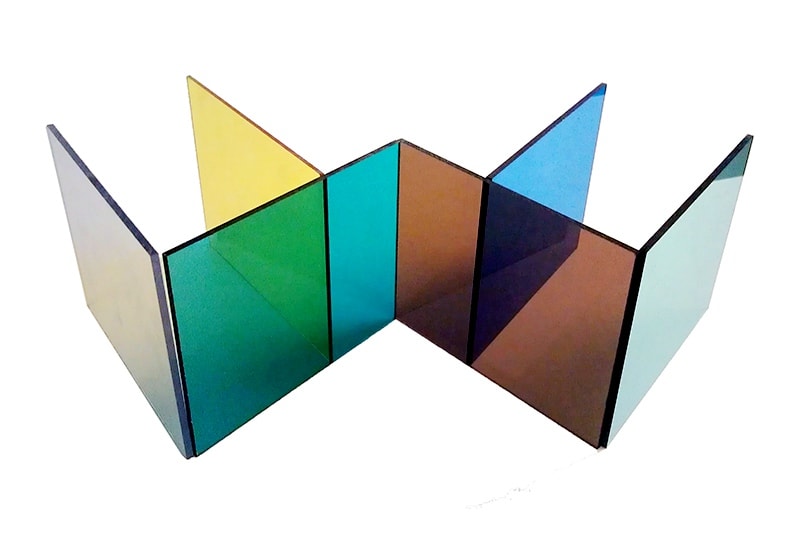

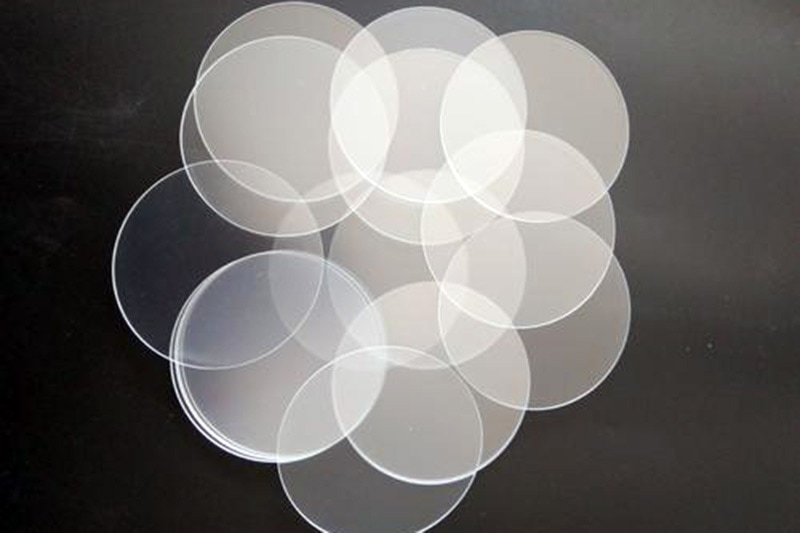

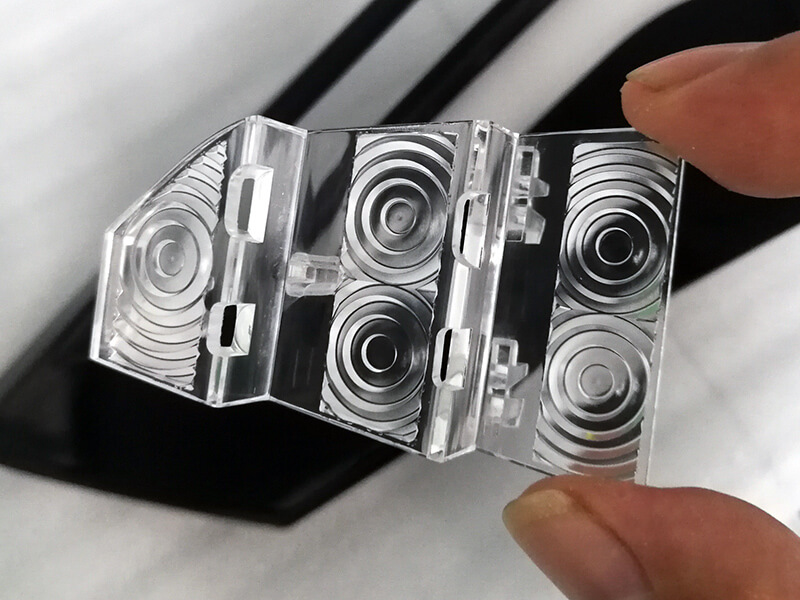

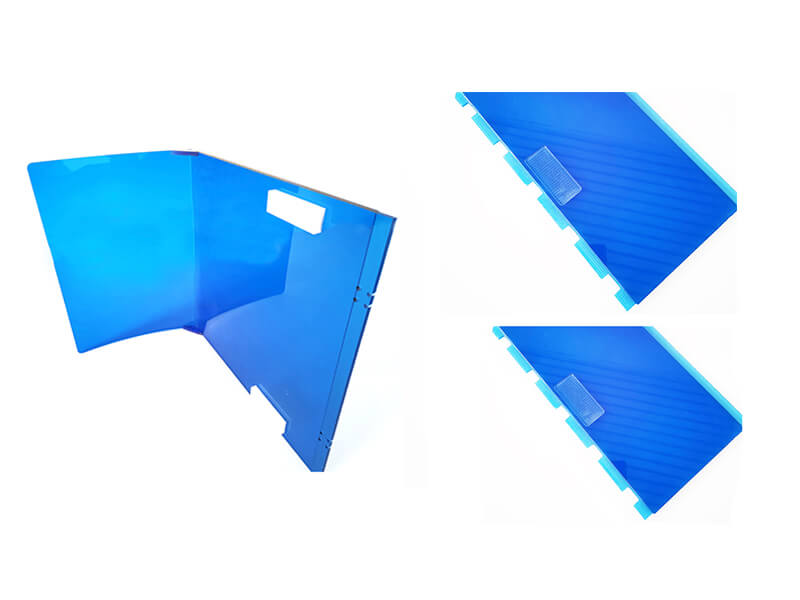

UVPLASTIC Polycarbonate Tube is made of transparent polycarbonate plastic granules by extrusion processing. It is a transparent plastic tube with high impact resistance, good flammability, low water absorption rate, and excellent electrical properties. Compared with acrylic tubes, polycarbonate tubes offer similar light transmittance and density but higher strength, temperature resistance, ultraviolet intensity, etc.

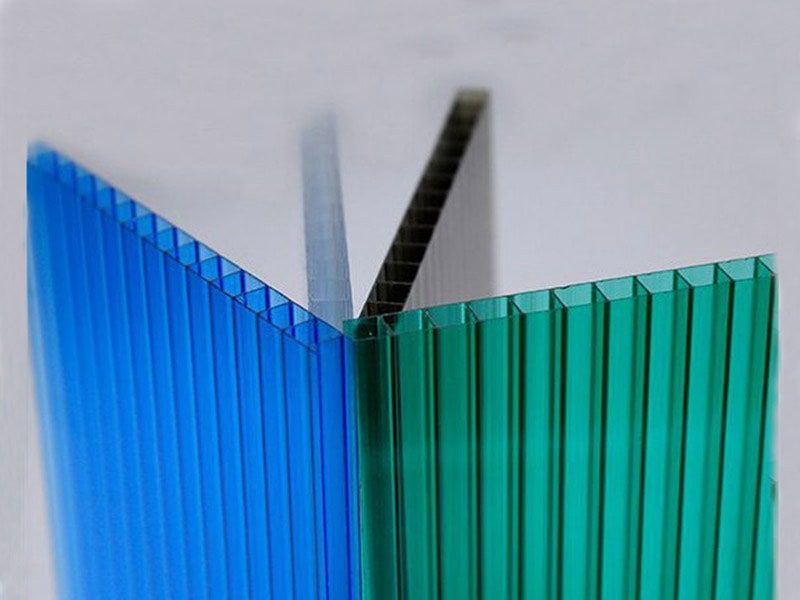

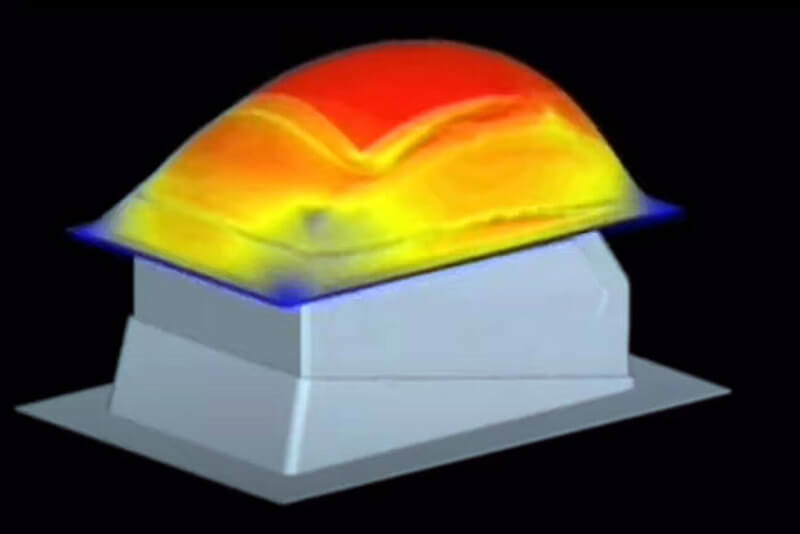

Most polycarbonate tubes are clear, but they can also be manufactured with custom colors subject to the Minimum Order Quantity. Sometimes, they are made with a light diffuser function for LED light. As one of the frequently-used clear plastic tubes, the polycarbonate tube works well from -40°C to 120°C and is used frequently for industrial applications in the auto industry, packaging display, electronic components, mechanical components, etc.

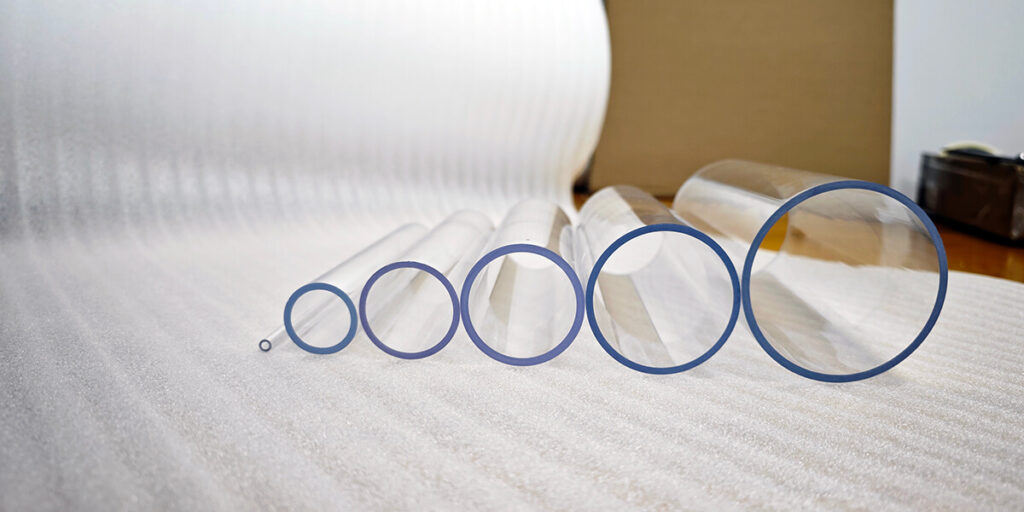

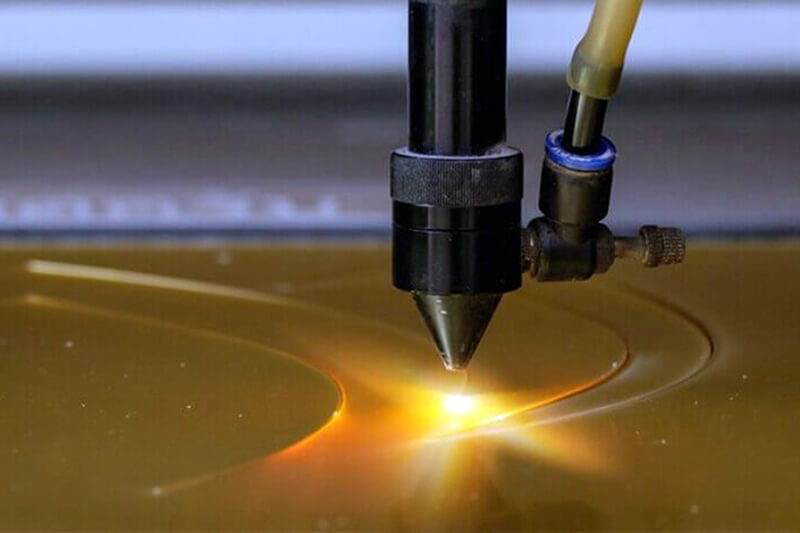

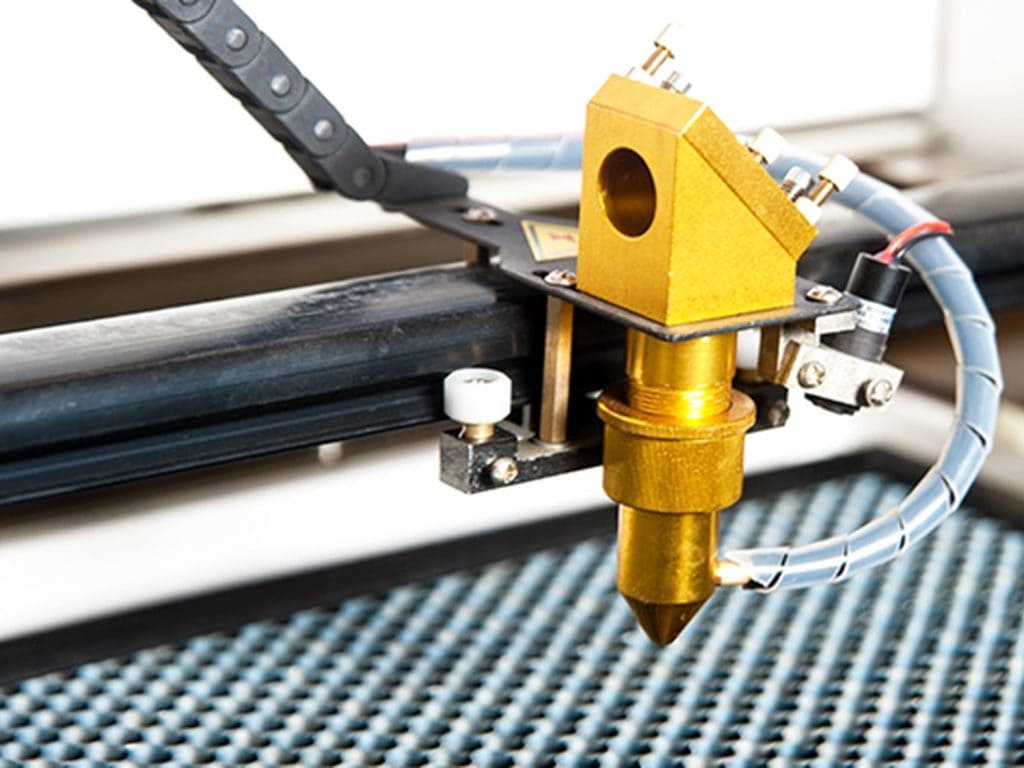

UVPLASTIC is a leading manufacturer of polycarbonate tubes in China. We stock polycarbonate tubes with an outer diameter from 5mm to 400mm. In the meantime, we can machine polycarbonate tubes by using a saw and turning-lathe machines.

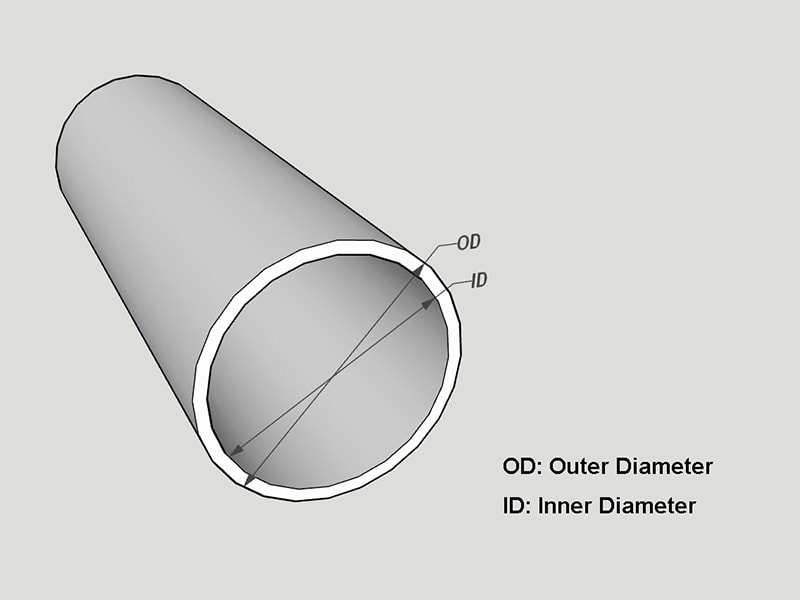

Specification Of Polycarbonate Tubes

Basic information about polycarbonate tube

| No | Item | Description |

|---|---|---|

| 1 | Product Name | Polycarbonate Tube |

| 2 | Model | UVPC-TU-OD-ID |

| 3 | Outer Diameter (OD) | From 5mm to 400mm |

| 4 | Thickness (T) | From 0.8mm to 6mm |

| 5 | Standard Length | 1000mm, 2000mm |

| 6 | Custom Length | Available |

| 7 | Material | Sabic |

UVPLASTIC polycarbonate tube size

UVPLASTIC stocks polycarbonate tubes with outer diameters from 5mm to 400mm for fast delivery and thicknesses from 1mm to 5mm. Meantime, we provide machining services.

Remark

Physical Properties of Polycarbonate Tubes

| Property | Test Method | Testing Condition | Unit | Value |

|---|---|---|---|---|

| Density | D-792 | g/cm3 | 1.2 | |

| Heat Deflection Temperature | D-648 | Load: 1.82 MP | °C | 135 |

| Short Time Service Temperature | °C | from -50 to +130 | ||

| Long Time Service Temperature | °C | from -40 to +100 | ||

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 | |

| Thermal Conductivity | C-177 | W/m K | 0.21 | |

| Tensile Strength at Yield | D-638 | 10 mm/min | Mpa or N/mm² | >65 |

| Tensile Strength at Break | D-638 | 10 mm/min | MPa or N/mm² | >60 |

| Elongation at Yield | D-638 | 10 mm/min. | % | 6 |

| Elongation at Break | D-638 | % | >95 | |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | MPa | 2350 |

| Flexural Strength | D-790 | 1.3 mm/min. | MPa | 100 |

| Flexural Modulus | D-790 | 1.3 mm/min. | MPa | 2600 |

| Impact Falling Weight | ISO 6603/1 E50 | 3mm sheet | J | 158 |

| Flammability rate | UL 94 | V-2 or V-0 |

The default third-party testing organization is SGS;

Main Benefits

UL Flammability Standard Released By Underwriters Laboratories

UVPLASTIC Polycarbonate Tube can meet the V-2 fire rating according to UL94

Restriction Of Hazardous Substances

UVPLASTIC offers environmentally-friendly polycarbonate sheets and meets RoHS and REACH