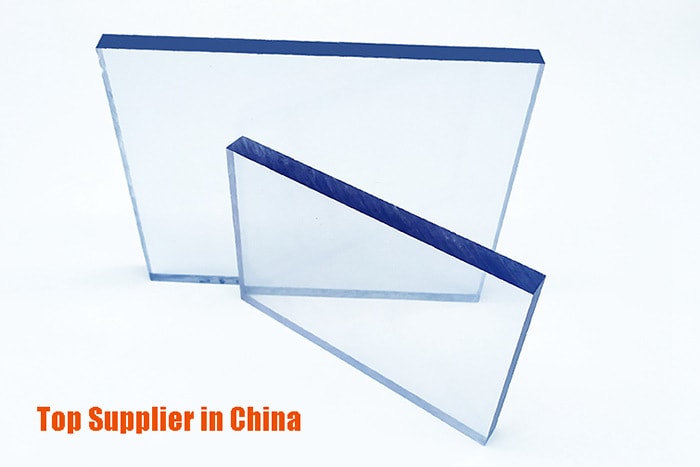

Enhanced Scratch Resistant Polycarbonate Sheets

Durch Beschichtung von Polycarbonatplatten

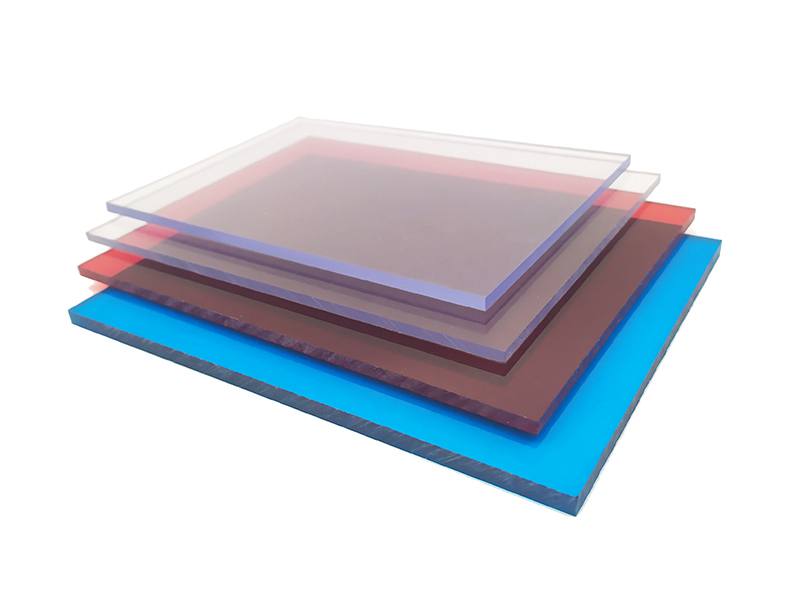

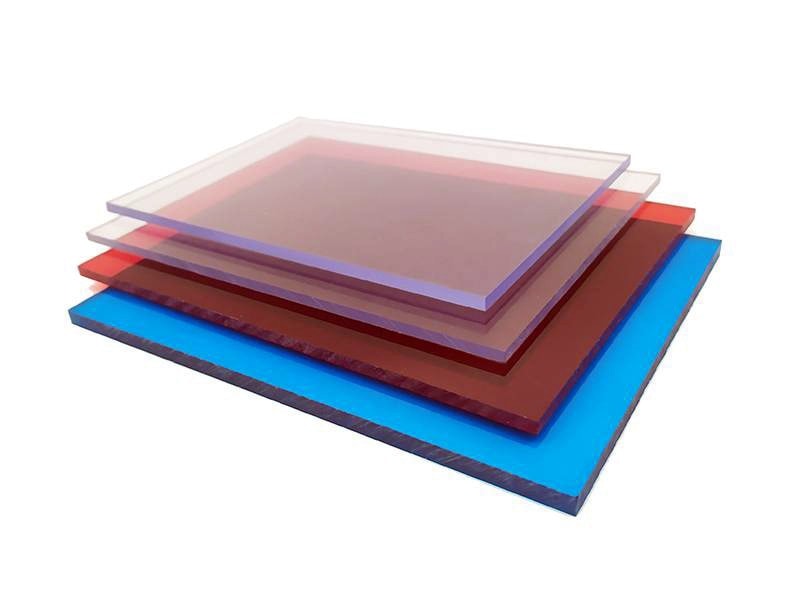

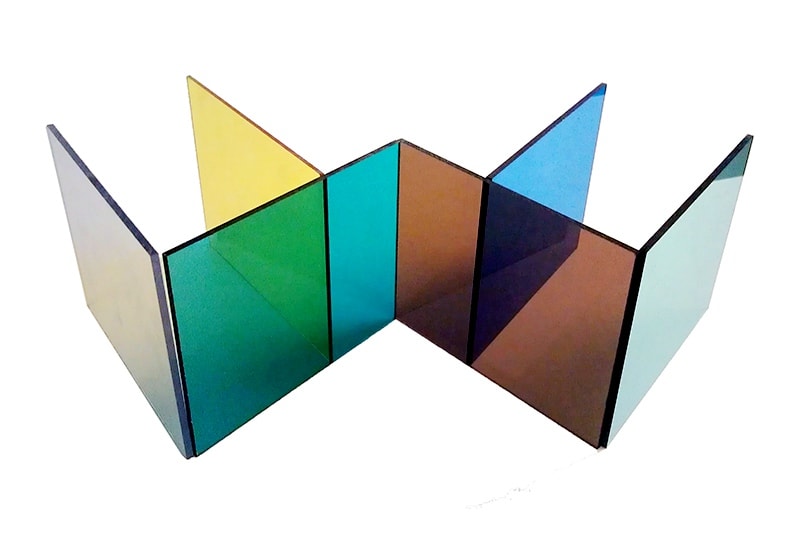

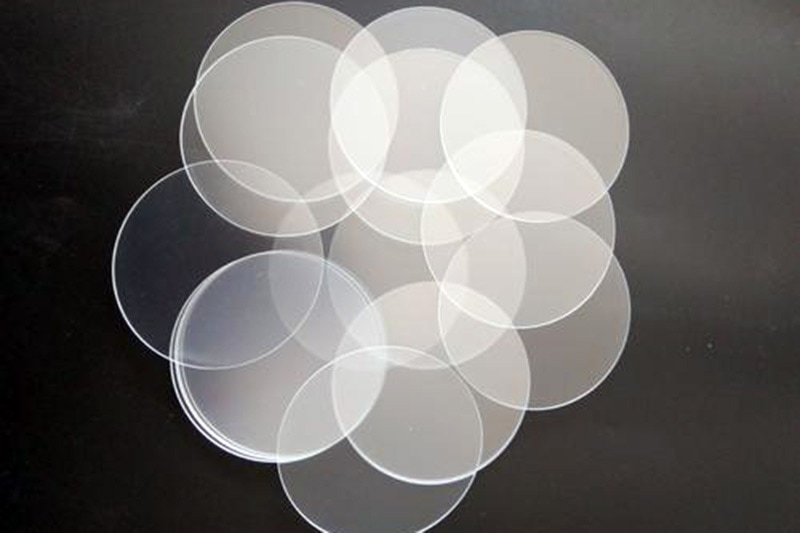

UVPLASTIC Scratch Resistant Polycarbonate is a coated polycarbonate, therefore, it offers the intrinsic properties of solid polycarbonate sheet. Meantime, it offers enhanced surface properties, including Scratch Resistance, Abrasion Resistance, Chemical Resistance, and excellent UV Protection. UVHPC is the family code of UVPLASTIC Scratch Resistant Polycarbonate, including two series of products according to different applications and functions.

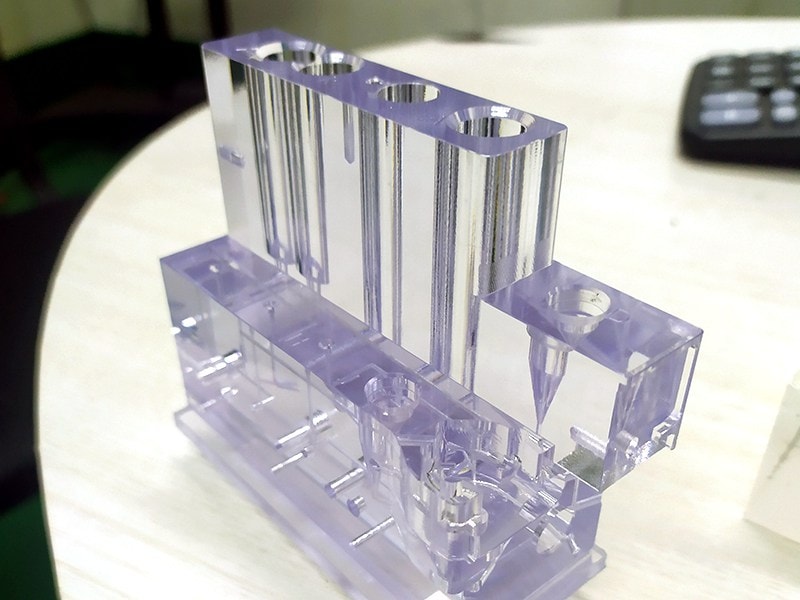

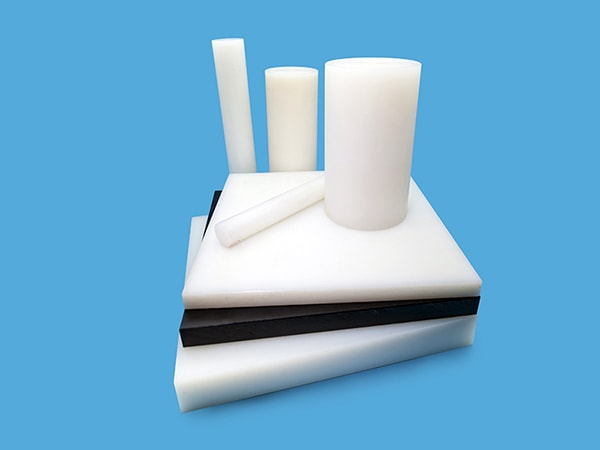

By advanced coating technology, UVPLASTIC is providing Scratch Resistance Polycarbonate with a wide range in thickness from 0.125mm to 18mm, which is used as screen protection, vehicular glazing, safety glass, bullet-proof glazing, laminated glass, etc. Otherwise, UVPLASTIC provides machining services, including silk-screen printing, cutting, thermal forming, drilling, CNC machining, and rapid prototyping service to global clients.

As a leading manufacturer of scratch-resistant polycarbonate in China, UVPLASTIC is providing cost-effective products to more than 2000 clients from more than 40 countries.

Scratch Resistant Polycarbonate Specification

Scratch-resistant polycarbonate for indoor use

| Item | Model | Thickness (mm) | Standard Size (mm) | Description | Applications |

|---|---|---|---|---|---|

| Scratch-resistant Polycarbonate (Thin) | UVHPC-SRT | 0.125mm, 0.25mm, 0.375mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm | 900x1830mm; 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Only flat application; 4. For indoor applications; | Front panel, Display screen |

| Scratch-resistant Polycarbonate (Normal) | UVHPC-SR | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm | 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Only flat application; 4. For indoor applications; | Machine guard, Bullet |

| Abrasion-resistant Polycarbonate (Mar-resistant) | UVHPC-MR | 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm | 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Only flat application; 4. For indoor applications; | Indoor display window, Photo frame |

| Scratch-resistant Polycarbonate (Bendable) | UVHPC-SRB | 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm | 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Can be bent to an angle; 4. For indoor applications; | Machine safety guard |

Scratch-resistant polycarbonate for outdoor use

| Item | Model | Thickness (mm) | Standard Size (mm) | Description | Applications |

|---|---|---|---|---|---|

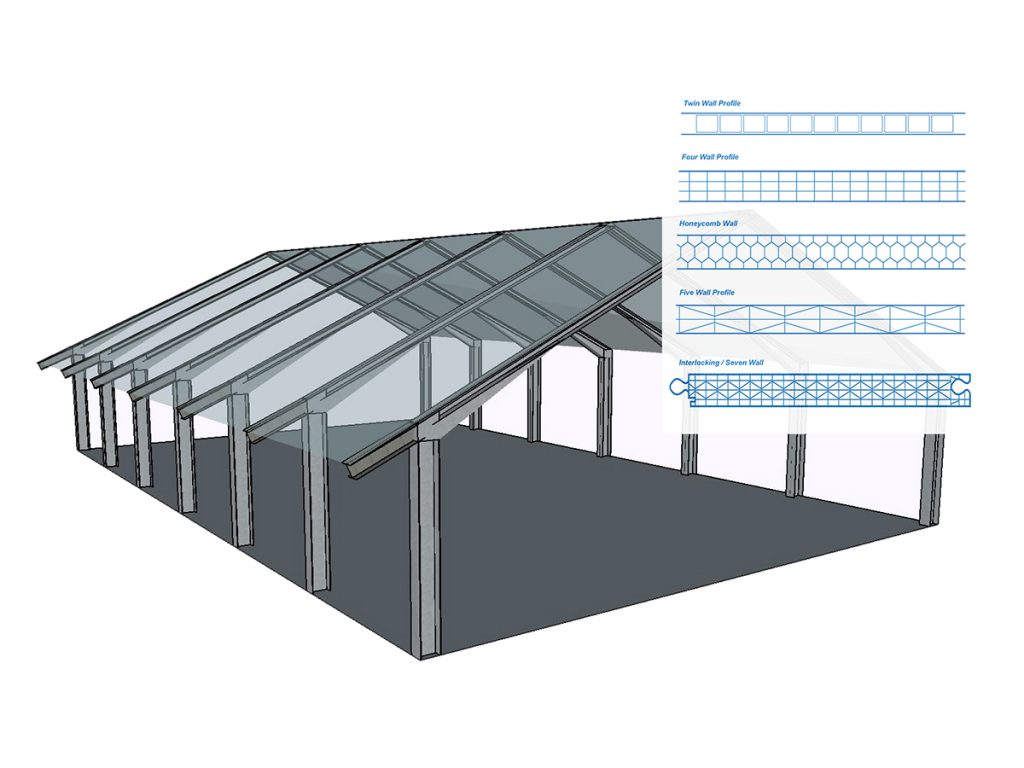

| Scratch-resistant Polycarbonate (Normal) | UVHPC-SRU | 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm | 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Only flat application; 4. For outdoor applications; 5. Good weather performance, 10 years warranty against breakage and 7 years warranty against yellowing; | Security glazing, Front panel, Display screen, Machine guard |

| Abrasion-resistant Polycarbonate (Mar-resistant) | UVHPC-MRU | 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm | 1190x2440mm; 1220x2440mm; | 1. One or two coating sides; 2. Excellent scratch resistance; 3. Only flat application; 4. For outdoor applications; | Lamination with glass in bullet-resistant glazing panels; |

| Scratch-resistant Polycarbonate (Formable) | UVHPC-SRUF | 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm | 1190x2440mm; 1220x2440mm; | 1. For outdoor applications; 2. Excellent scratch resistance; 3. Can be formed to arch or dome shape; 4. Can be cold curved or drape formed; | Face mask, car window, windshield |

Physical Properties

| Physical Properties | Test Condition | Standard Value | Unit | Test standard |

|---|---|---|---|---|

| Density | 1.2 | g/cm3 | ISO 1183 | |

| Taber haze | 500 g, 100/500 | From 1% to 10% | % | ASTM D1044 |

| Abrasion Resistance | 0000# steel wool, with 250 g/cm2 pressure, 5 cm stroke reciprocating for 25 times | No Damage | ||

| Hot Water Resistance | 80°C (hot water) × 10 min | No Change | ||

| Moisture Resistance | 70°C × 80% RH × 48h | No Change | ||

| Heat Resistance | 80°C×40min | No Change | ||

| Coated sample hardening layer wiped with absorbent cotton ball fully immersed in the test solution, then sealed with PE film, left at room temperature for 24 h, rinsed with water, then observation. | -30°C×10h | No Change | ||

| Cold & Heat Cycle Test | From -30°C to 23°C (9h) | No Change | ||

| Adhesion | Cross-hatching test 3M tape (5 times) | No Detaching | ||

| Tensile Strength | 60 | MPa | ISO 527 | |

| Flexural Strength | 85 | MPa | ISO 178 | |

| Ethanol Resistance, Weak Acid Resistance (0.5%) Salt Water Resistance | Coated sample hardening layer wiped with absorbent cotton ball fully immersed in test solution, then sealed with PE film, left at room temperature for 24 h, rinsed with water, then observation. | No Change | ||

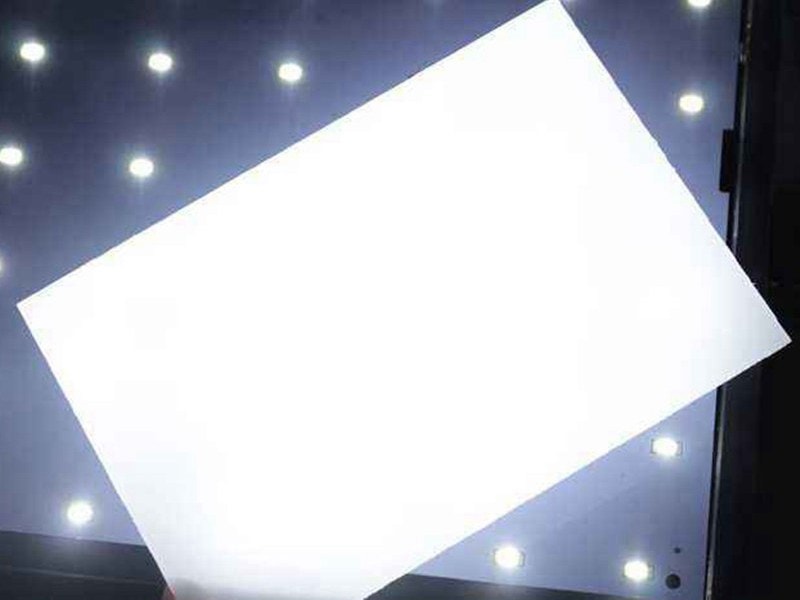

| Transmittance | Thickness from 1mm to 15mm | From 82% to 92% | % | ASTM D1003 |

Main Benefits Of UVPLASTIC Scratch Resistant Polycarbonate

Applications

Motorcycle Windshield

Golf Buggy Windshield

Train Windshield

Car Windshield

Bullet-Proof Glass

Display Screen Of Instruments