Leading Four Wall Polycarbonate Sheet Supplier In China

Four wall Polycarbonate Introduction

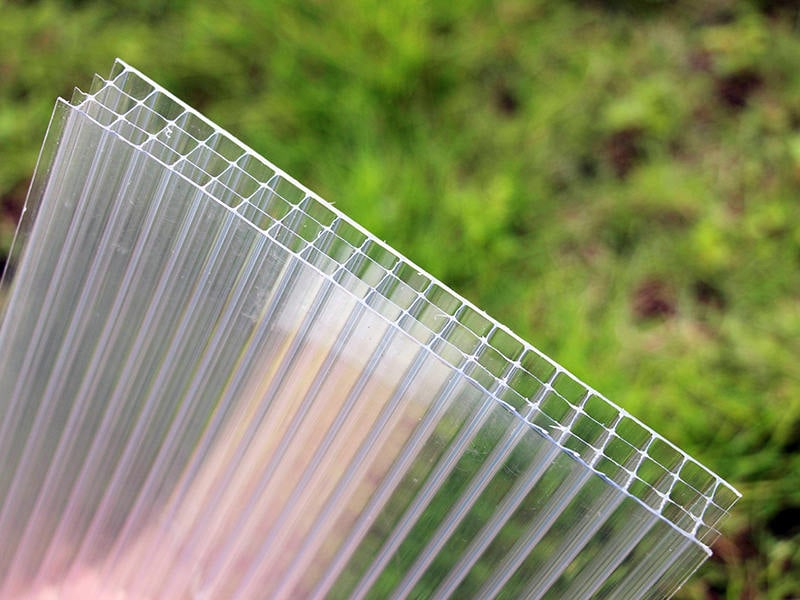

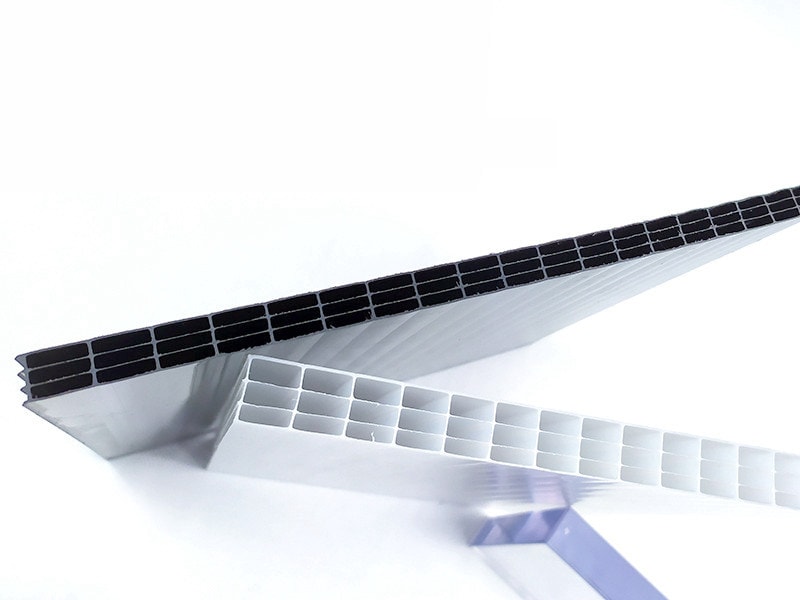

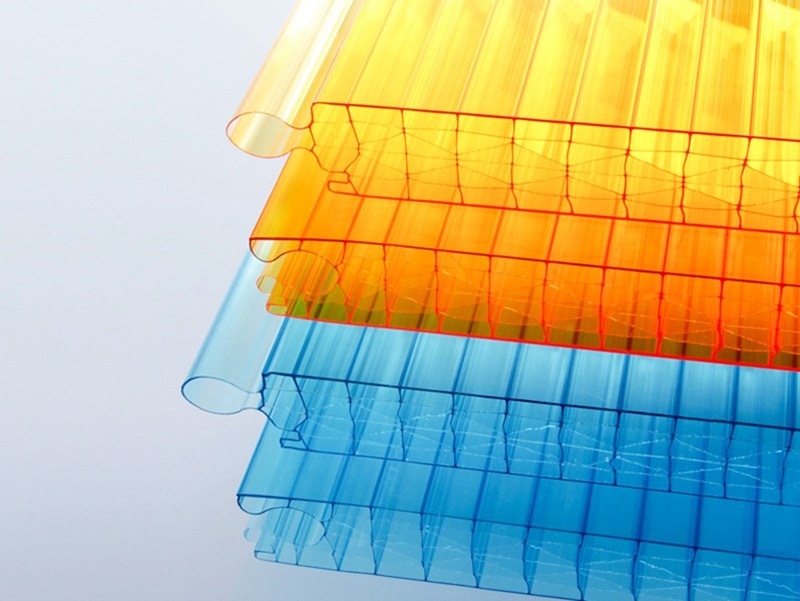

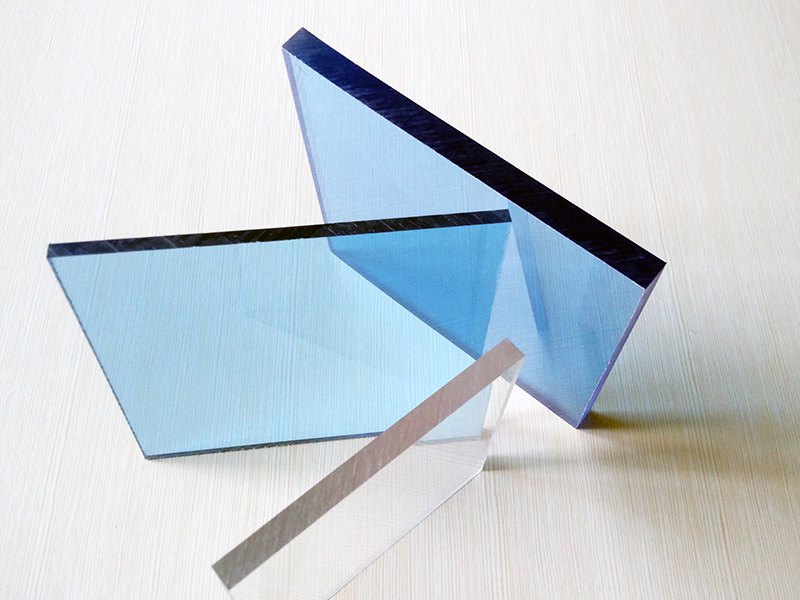

Four Wall Polycarbonate Sheet is significantly lighter than glass but stronger, more flexible, and more impact resistant. Therefore, it is a versatile roofing material, the color can be transparent and translucent. Normally, the co-extruded UV protective layer(s) is/are co-extruded on one or both sides, therefore, it can withstand the rigors of daily abuse in an outdoor environment for more than 10 years or 15 years.

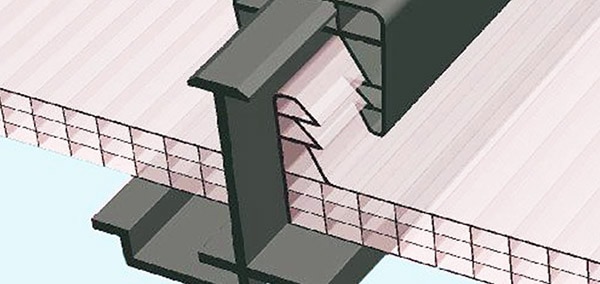

It has four walls and creates three parallel insulation channels. This design adds both impact toughness and the ability to support the large weight. Meantime, four wall polycarbonate sheet offers preferential thermal insulation property. Four wall polycarbonate sheets are widely used for roofing, facade system, and the partition wall between rooms.

UVPLASTIC is one of the leading manufacturers of four-wall polycarbonate sheets in China. With more than 15 years of experience in the polycarbonate plastic field, we provide standard four-wall polycarbonate, meantime, provide custom sheets. Today, we are providing high-quality products to more than 600 clients in 40 countries.

Product Specification About Four Wall Polycarbonate

Products Range

UVMPC-FO Four wall polycarbonate is one member of multiwall polycarbonate, the thickness is from 8mm to 20mm.

| Model | Description |

|---|---|

| UVMPC-FO-U1 | Standard four-wall polycarbonate sheet with co-extruded UV protective layer on one side; |

| UVMPC-FO-U1A | Standard four-wall polycarbonate sheet with co-extruded UV protective layer on the outside, the anti-fog coating on inside for greenhouse wall and roofing; |

| UVMPC-FO-U2 | Standard four-wall polycarbonate sheet with co-extruded UV protective layers on two sides |

Standard Size

| Model | Thickness | U-Value (W/m²·°K) | Light Transmission, clear, % | Width 700 (mm) | Width 1050 (mm) | Width 2100 (mm) |

|---|---|---|---|---|---|---|

| UVMPC-FO-8 | 8 mm | 2.85 | 58 | ✔ | ✔ | ✔ |

| UVMPC-FO-10 | 10 mm | 2.16 | 57 | ✔ | ✔ | ✔ |

| UVMPC-FO-12 | 12 mm | 1.98 | 56 | ✔ | ✔ | ✔ |

| UVMPC-FO-14 | 14 mm | 1.74 | 55 | ✔ | ✔ | ✔ |

| UVMPC-FO-16 | 16 mm | 1.56 | 53 | ✔ | ✔ | ✔ |

| UVMPC-FO-18 | 18 mm | 1.4 | 50 | ✔ | ✔ | ✔ |

| UVMPC-FO-20 | 20 mm | 1.24 | 48 | ✔ | ✔ | ✔ |

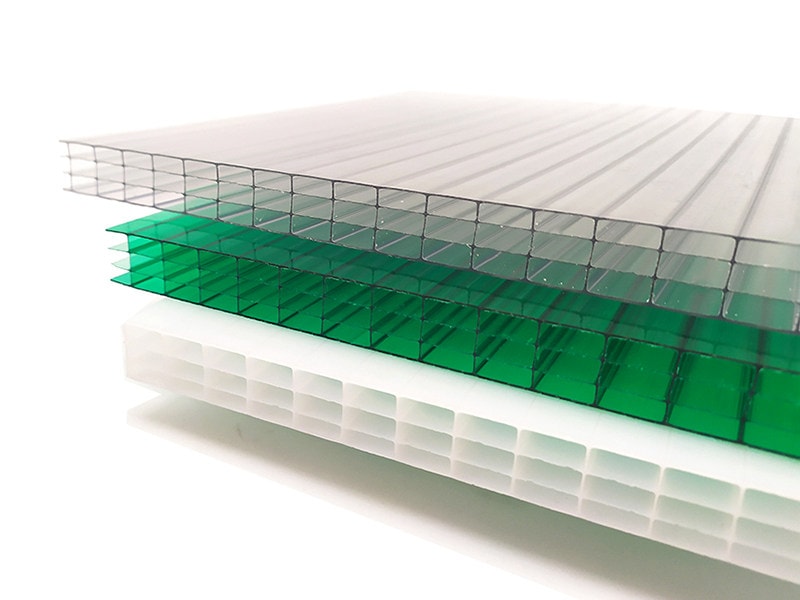

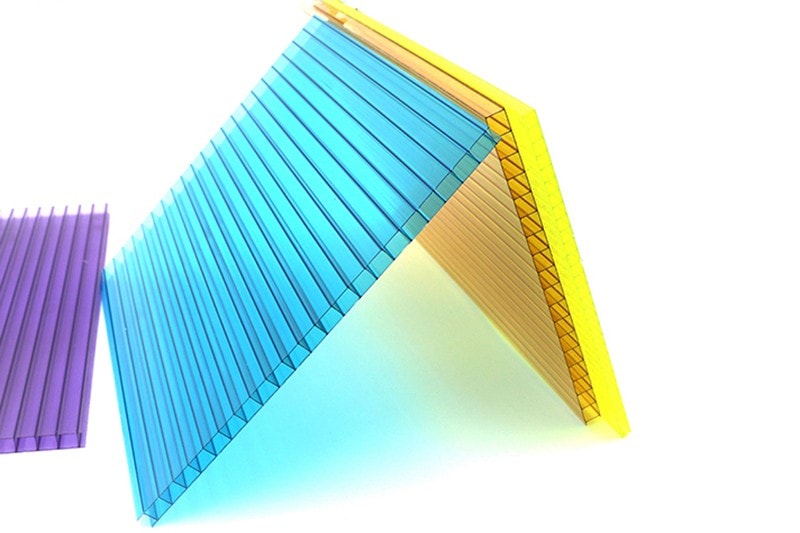

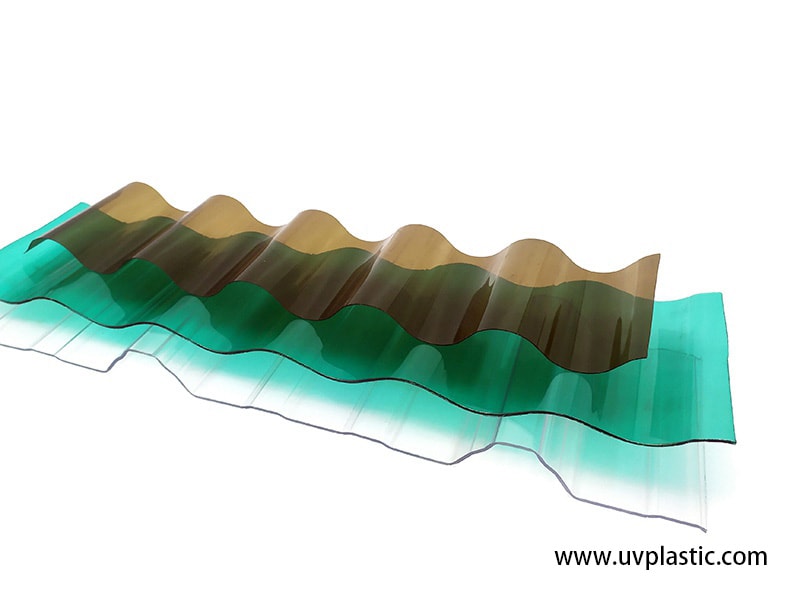

Color Options

| Model | Clear | Bronze | White/Opal | Green | Blue | Custom color |

|---|---|---|---|---|---|---|

| UVMPC-FO-8 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-10 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-12 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-14 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-16 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-18 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UVMPC-FO-20 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Physical Properties

| Optical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Light transmittance | D-1003 | % | >63 |

| Tensile Strength at Yield | D-638 | Mpa or N/mm² | >60 |

| Tensile Strength at Break | D-638 | MPa or N/mm² | >65 |

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 |

| Thermal Conductivity | C-177 | W/m K | 0.21 |

| Elongation at Break | D-638 | % | >100 |

| Tensile Modulus of Elasticity | D-638 | MPa | 2400 |

| Flexural Strength | D-790 | MPa | 100 |

| Fire rating | UL 94 | / | V1 |

Default third-party testing organization is SGS